csmitty

ArboristSite Lurker

Hey guys, first post here along with first saw, though not new to them. I picked up a used 460, and 06 that had a bad mix and scored the piston and lightly got the cylinder walls. So planning on replacing those. Are the big bore kits from Baileys worth the money or should just go with Stihl replacements or like a Weisco 52mm?

Next the porting. I've read on the muffler porting, but is there also some cylinder porting that can be done? I guess maybe I'm getting the same muffler mod confused when I hear porting with out the muffler mentioned. Mine is the non DP. So was thinking of just doing it myself since I have a TIG for some baffling.

Any other mods that can be done while its torn apart? He said it probably less than 50 hrs when it got tore up. Been sitting for 2 years. but had all the fluids drained. Be worth it to check the vacuum/pressure?

Thanks!!

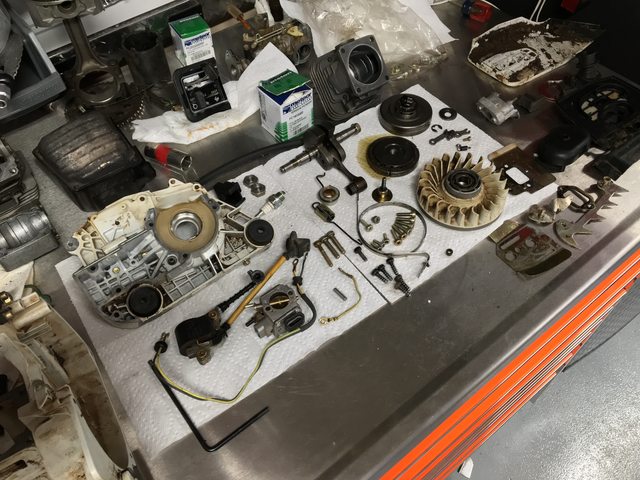

Some pics for your viewing pleasure

Next the porting. I've read on the muffler porting, but is there also some cylinder porting that can be done? I guess maybe I'm getting the same muffler mod confused when I hear porting with out the muffler mentioned. Mine is the non DP. So was thinking of just doing it myself since I have a TIG for some baffling.

Any other mods that can be done while its torn apart? He said it probably less than 50 hrs when it got tore up. Been sitting for 2 years. but had all the fluids drained. Be worth it to check the vacuum/pressure?

Thanks!!

Some pics for your viewing pleasure