Thanks Mark.

Do I hear an echo?

Do I hear an echo?

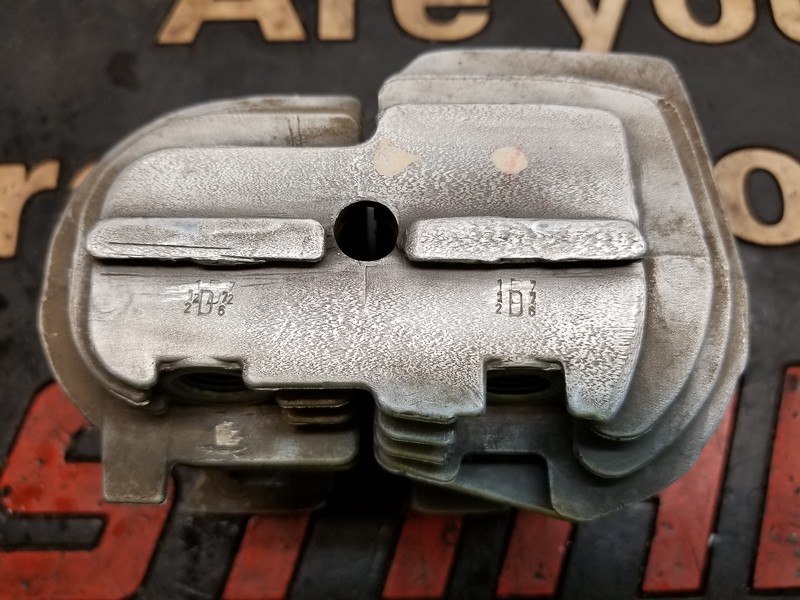

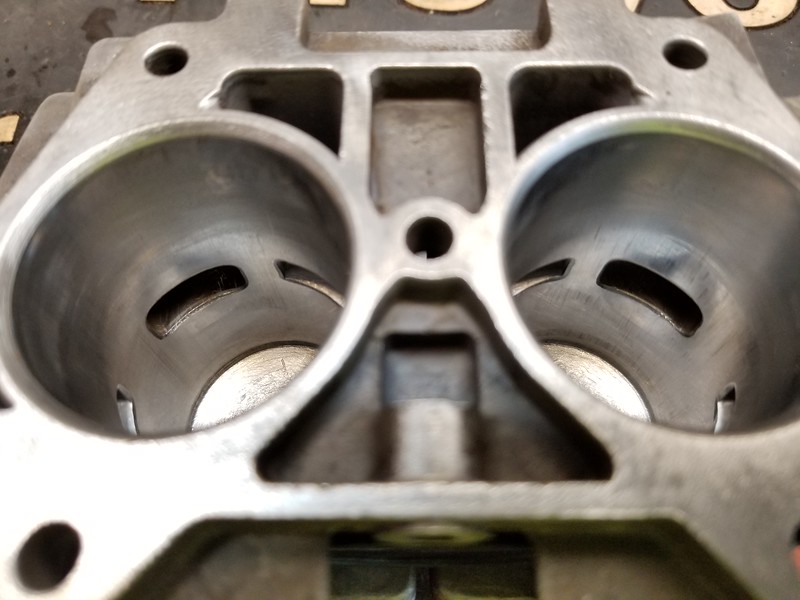

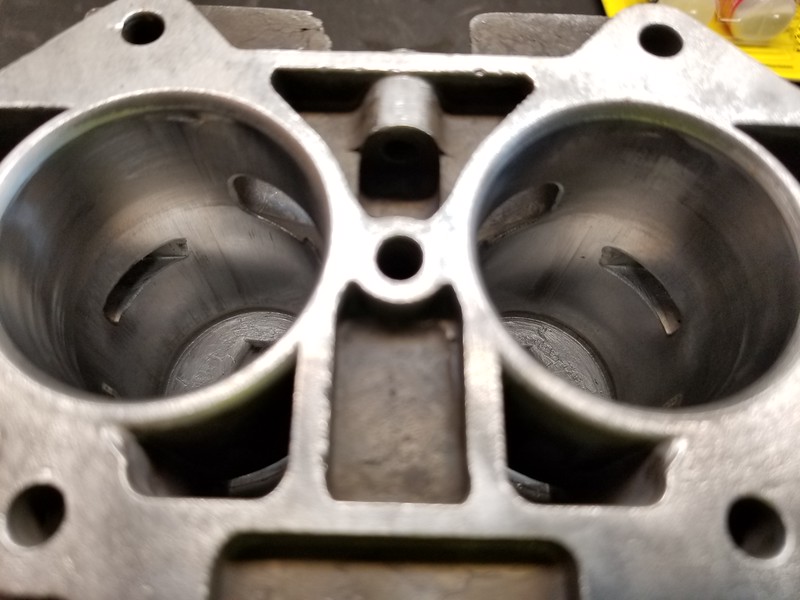

I thought they were identical until I tried to bolt the outer one to the CC. With just a hair of trimming, I believe they would be swappable. The bolt pattern is the same.Do you happen to know if there are differences in the inner and outer spikes? Mine only has an inside one at this moment and judging from my photos the spikes appear to be a bit longer.

View attachment 598128

Maybe just the perspective in the photos.

Mark

Nothing serious. They just took my colon out, lolCongrats on getting that treasure going. Didn't know that you had been out of commission, hope it wasn't serious, and glad to hear that you can go all night without compromise.

Please forgive my memory, but did you or 3000 FPS do the welding for me?

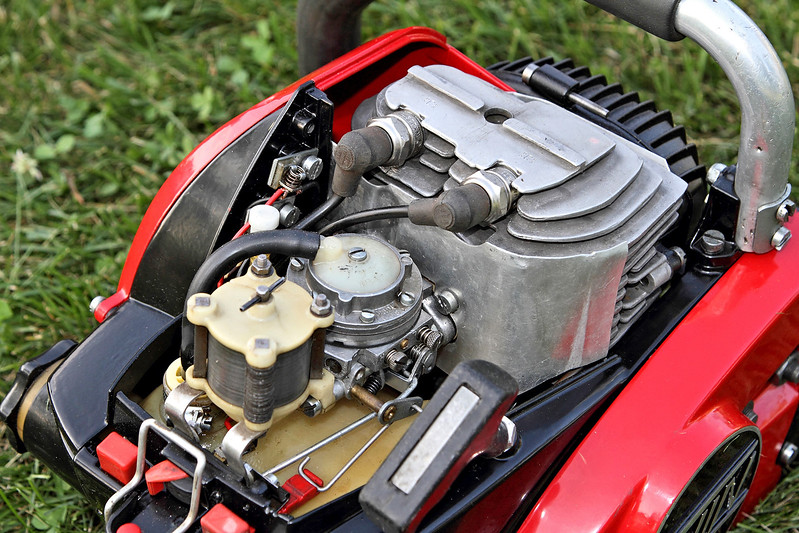

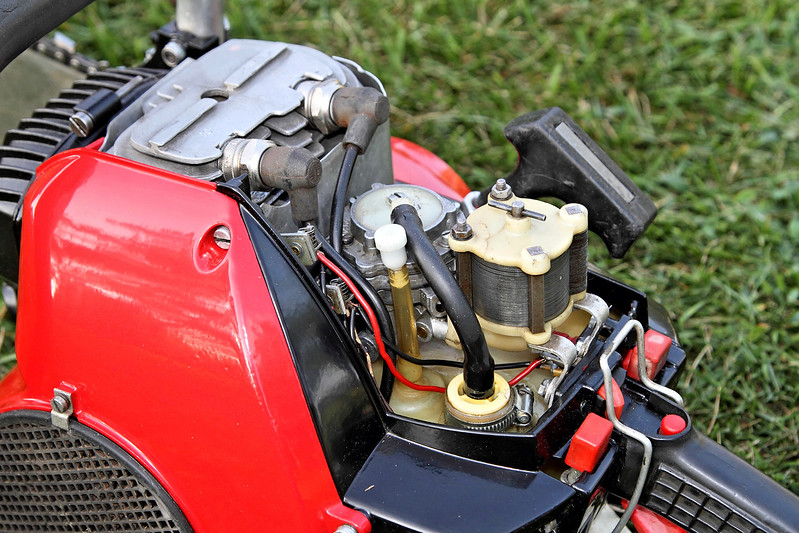

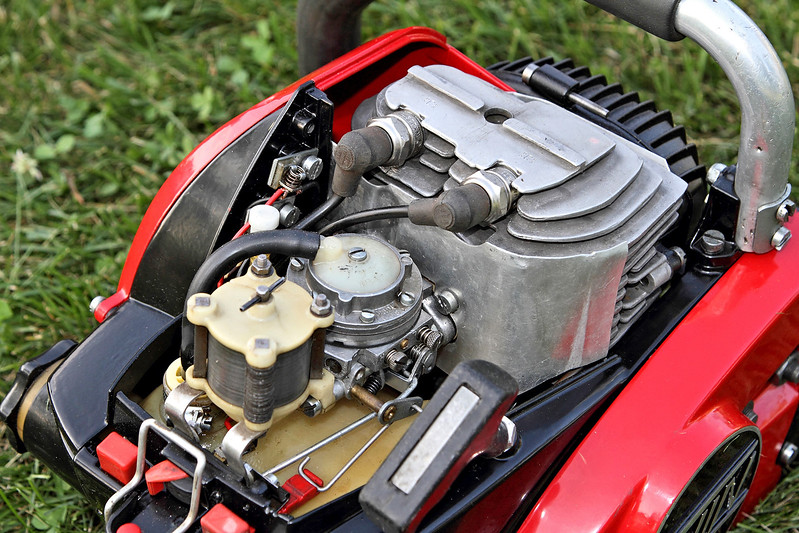

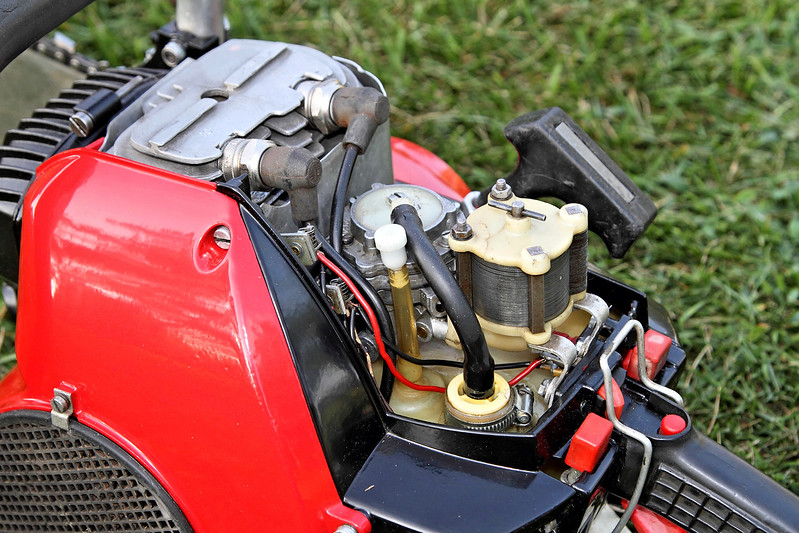

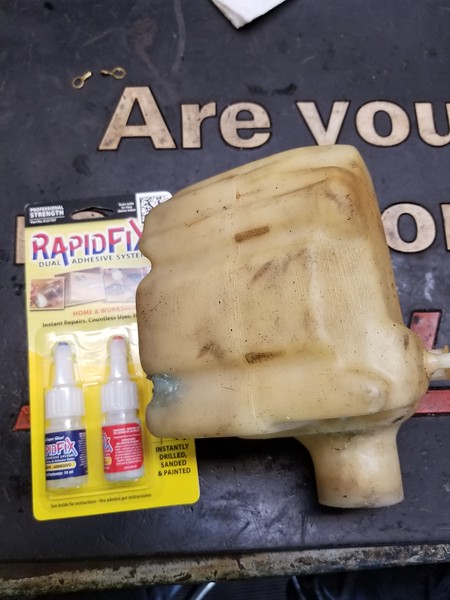

Glamour Shots!

Nice job Brad. Thinking I had that saw in my possession for a bit. She sounds great

and now gives me a little inspiration to get mine up and running.

Hope your feeling better.

Lee

That's a HORRIBLE job, lol. I'll have to measure it.Is that handle 3/4" ?

I'd gladly install new hose if so.

That's a HORRIBLE job, lol. I'll have to measure it.

Oh wow, must be a post on that, glad your better. You have the most interesting posts, but this is well, wow. JRNothing serious. They just took my colon out, lol

I APPRECIATE THE OFFER!After installing a couple of 10' rolls, I'm fairly good at it.

Enter your email address to join: