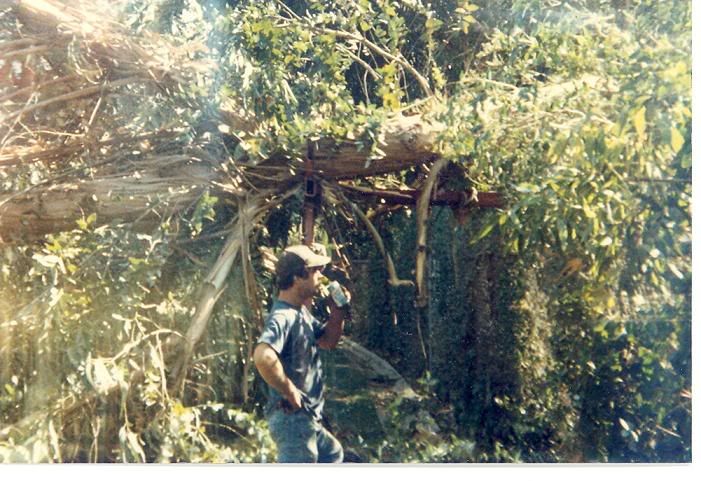

The year was 1986,

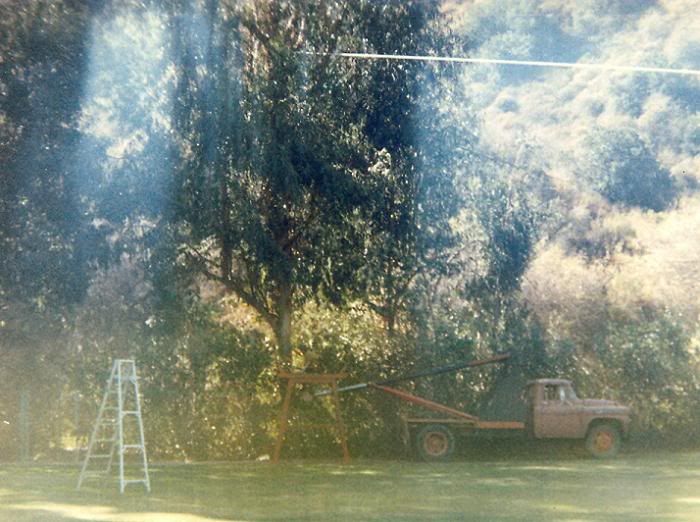

I got a call from the Cemetery they wanted a price on removing abot 85 Eucalyptus

trees. The trees were along there property line on the other side of a 6ft fence.

They wanted the trees cut off at ground level. The trees were abot 4 to 8 feet in

from the fence. There was no access from the other side it droped down in to a

a natural strom drain. All around the trees were large bushes that they did not

want damaged. So to climb each tree and and lower all the limbs and wood down by

ropes. This would work but would smash down some of the bushes right by the trees

and they did not want this to happen. A crane that would work but cost to much and

they would not allow heavy equipment like that to drive on there lawns.

So I got this idea. I went home and started drawing up my idea. When I was

at the Cemetery I took mesurements. The next day I turned in my bid.

Abot three days later they told me I got the job. Off to the steel yard I went to

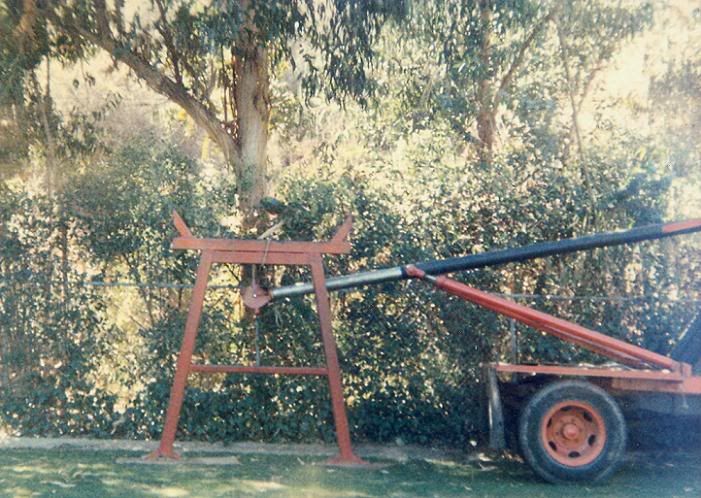

get heavy duty 3x5 box tubing 1/4 thick and a few other steel items. In my

garage I built my tree catching stand. Cutting,grinding and welding and

in a few nights after work I had it done. This for me was exciting to try out

because if this worked well it was going to save so much time and make this

job very profitable. It would also make it easy to do. Some of these trees

were close to 100ft tall. Chainsaws we were using 056, 064 stihl Super EZ

Super XL and Super XL925. This stand is 7ft 6inch tall, 6ft wide at the top,

Has a 10ft long arm with sharks teeth on the end.

What we did was clamp the end with the sharks teeth to the tree with a

chain and binder. I took my little 59 chevy boom truck and hooked on to the

stand and pulled down on it to keep it from moving.

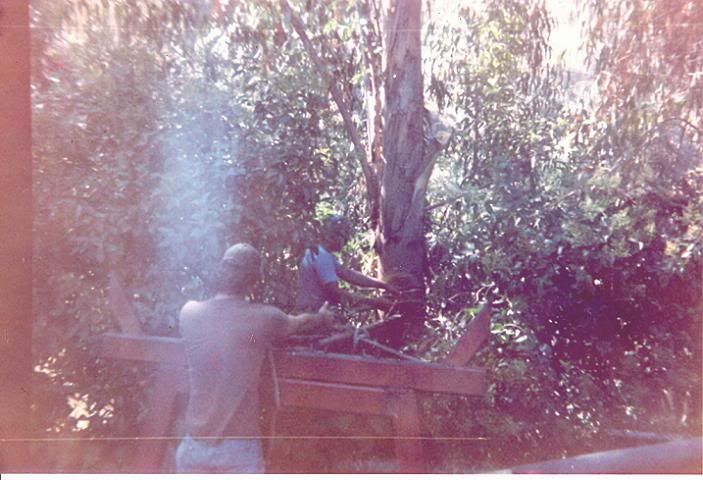

In every tree we would first put a rope in it to pull it over with.

After we fell the tree I would take the boom truck and lift the tree

off of the stand and saw it up.

This tree catching stand worked out very good. It was great.

I still have it but have not used it in over 20 years

Heres some pics there old and not real great.