You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

whadja do today?

- Thread starter treevet

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

JRoland

ArboristSite Operative

Cooled off and super windy today here. Unseasonably warm lately though, even for California.

Logging in February!

Logging in February!

JeffGu

Antagonist/Heckler

40's here... supposed to hit 60 this week... watched the white stuff melting away while we worked on the shop today. Tonight, playing with video editing software. I broke down and bought a GoPro because I didn't want to be the only guy left on the planet that doesn't have one. Gonna hook it to the dog tomorrow, and have some fun.

Yeah they will you just have to fight with them. I had the same issue with my engine cover and it was at the end of its five year warranty. I complained about it on bandits fb page, a lady got me in touch with an Ed Casper that's who you need to talk to.With the exception of where the machine catches rocks from its tires and the truck tires this is the main paint issue. Around the bolts on the hood. My guess is the bolts were stored in a light lubrication to prevent rust prior to assembly, not properly cleaned of oil and contaminates, pieced together and then painted. I had the control panel replaced under warrantee but bandit won't cover paint past one year.

DR. P. Proteus

Addicted to ArboristSite

- Joined

- Dec 2, 2013

- Messages

- 2,358

- Reaction score

- 1,356

Blog

Recent posts

Have you entered a tree climbing comp yet?

SRT - What is all the fuss about?

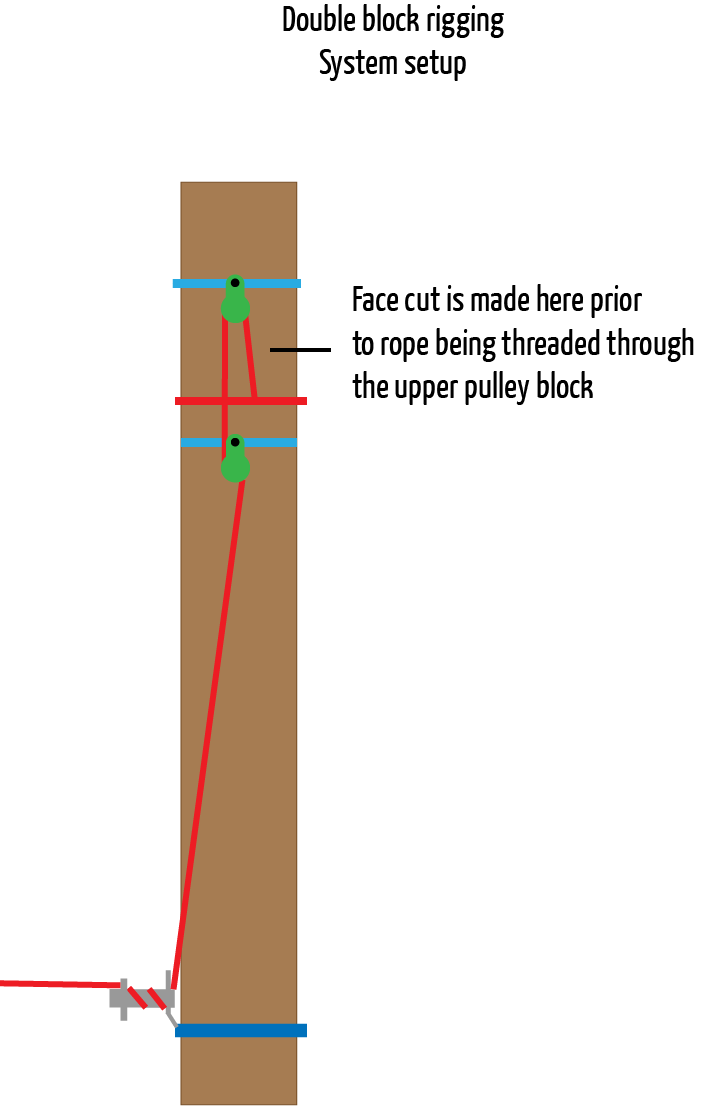

Double block rigging

Is DdRT really 2:1 mechanical advantage?

Double block rigging

Date: 11 January 2016

Written by: Daniel Holliday

I have been witness only once to the failure of rigging equipment when a colleague was removing a large London Plane tree about 8 years ago. London Plane is very dense and heavy wood. The tree had been pollarded multiple times over the years at the same point. When it came to rigging this piece out, he continued to tie up the chuck in a conventional negative rigging system around the whole of the pollard point. If a quick calculation had been done we would have known that once rigging off, the force this piece would generate would by far exceed some of the rigging component’s breaking strength. The inevitable happened and the rigging line snapped at the point where the knot had been tied. Luckily none of the crew where injured but a retaining wall and part of the driveway were damaged and this was a luxury property in St. Johns wood, London..

As Climbing Arborists we should constantly be looking for new ideas, techniques and equipment to use in order to overcome different tasks that we may be face in the future. This industry seems to be evolving everyday so we should always be trying to stay at the top of our game.

Think about the largest (in diameter) tree that you have removed. If it wasn’t rigged, imagine you had to rig this tree due to objects or structures below that couldn’t be damaged. When it comes to the point of rigging down huge chucks of wood from the stem you have a few options… Continue with your conventional negative rigging technique that you think “should be fine” when it comes to your rigging equipment and the chance something may fail. The next option is to start cutting down the grain, halving the pieces instead of cutting them thinner to prevent the rope from sliping off the piece. You may think cutting grooves in the piece for the rope to sit in is the way to go so you can cut a smaller piece but this is still a risky maneuver. Depending on the job there may be other options, but now lets throw double block rigging into our arsenal.

A few months ago I was shown the rigging technique ‘Double Block Rigging’ by Gareth Tudor-Jones of Bartlett Tree Experts. Gareth did some field-testing with this rigging technique using load cells to demonstrate its advantage and get real life readings and results.

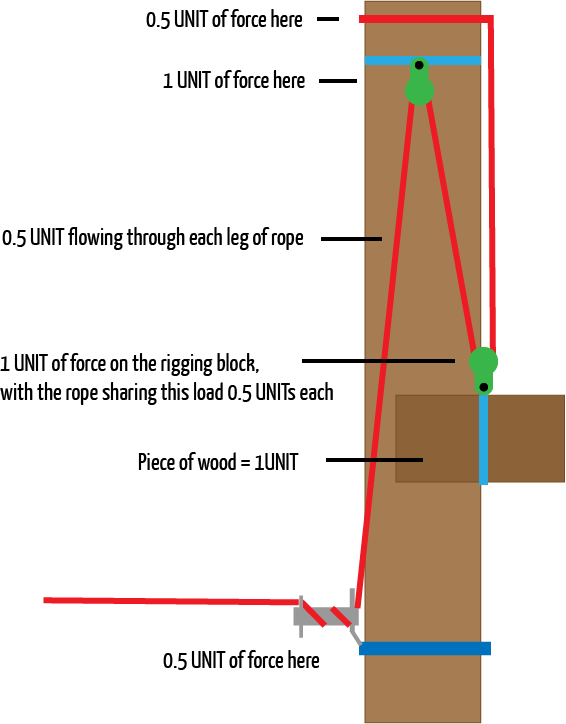

The double block rigging technique is a great technique for rigging large/heavy pieces as it helps to spread the force of the piece(s) being rigged. It uses more rope in the system to help absorb energy, using more components to help spread the load and reduce the shock load on the stem its self.

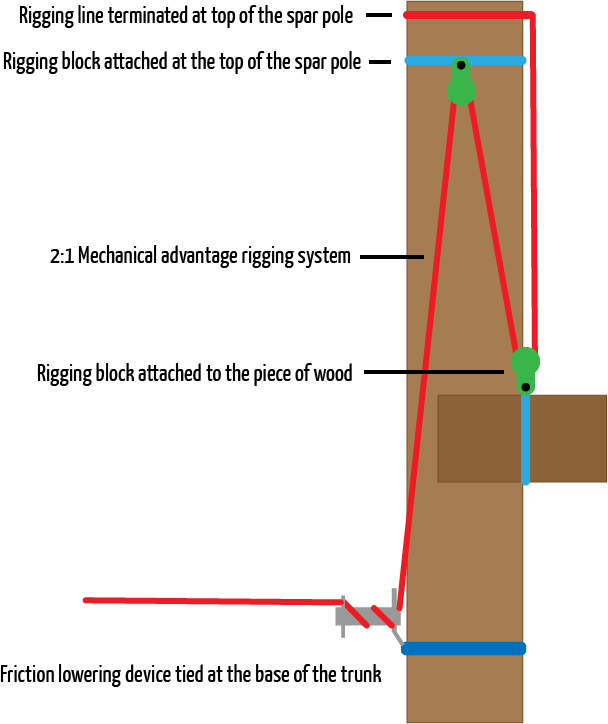

How it works

Looking at the illustration the first thing to note is that the rigging system has created a 2:1 mechanical advantage, this part of the system is where we get the greatest reduction in forces and load, as opposed to the conventional rigging system that actually multiplies the load at the block. In addition to the M/A this system requires 1/3 more rope, which equates to the rope absorbing force over a longer length of rope.

Looking at the system we can see three separate points of attachment, the termination of the rigging line, rigging block on the section of wood and the block on the top of the stem. Using a system with two pulley blocks like this one means that the load is spread between them, these are hugely important factors when thinking about the life span of your rigging components.

To the left is a video that demonstrates how to set up and execute this system.

To the right is an illustration including the field data gathered from Gareth Tudor-Jones (of Bartlett tree experts) to show how this system works in the real world.

One of the considerations Gareth needed to solve was to determine where the best termination end location was for DBR. Gareth decided to test various levels.

Level 1 - top of the spar pole

Level 2 - level with base of the rigging block

Level 3 - about 1 foot below the rigging block

However, this system is specialist and not the type of setup you would use on an everyday basis. There are some fairly obvious downsides to using the DBR system, to start with it is more time intensive to setup especially the first few times you use this system. Secondly you need more equipment for this setup, extra rigging block, additional rigging sling/strop and possibly a longer rigging line etc. You should select heavy duty rigging blocks if piecing down a stem, they would need smooth side plates as not to cause damage to the rope as the rigging blocks may twist.

To sum up, this is a system primarily for rigging large sections using a method designed to reduce excessive loading across your rigging components. It is a technique that due to the time disadvantage will require a specific job but is another great tool to add to your toolbox and helps open the mind a little more about they way we can configure our equipment to get different results. The next time you do a removal it would be worth giving this technique a try to familiarize yourself with it before executing it on larger pieces. Climb safe… Work safe…

Woof!

Somewhere around the four minute mark this guy hammers the living crap out of the top block. I didn't think that was very groovy at all. I mean the concept of the rigging is pretty cool, its just the smashing of the block that has me feeling a little queasy. You?

gorman

Addicted to ArboristSite

Had one of my groundies no show. Luckily it was the *******. Too bad we had this thing to do. Just one guy on the ground.

Pelorus

Uva uvam vivendo varia fit

The abuse of the block was mildly disconcerting, but taking 2X as long to setup and remove the rigging for each cut would get to me. Usually by the time I'm negative blocking a spar, I'm getting to the point of wanting to be out of the tree, and offa my spurs, so I can say goodbye / good riddance to my associates. Cause I want the misery to end as soon as possible, and anything that is gonna prolong it, like that method, is wrongo.

mckeetree

Addicted to ArboristSite

Some of our "competition" ended up getting the contract to take care of the trees on a commercial property we have had for the past 17 years. Yesterday they drove a loaded chip truck through the side of one of the buildings and took out an expensive fountain along with doing mega damage. I was told it was the unlicensed drivers sixth day to be in the United States. Oh well.

They might be giving you a call back.

Griff93

ArboristSite Operative

It's a swampy mess around here right now. It's frustrating having jobs to do and bills to pay but not being able to work due to the weather. I decided to get some stuff done in the shop until it dries out.

Finished a set of heavy duty jaws with teeth for a Branch Manager Grapple. We just don't have much luck with the jaws holding up. We love them otherwise. There three of these floating around between mine and a couple of friends that do tree work. Of these three we've had 5 small jaws and one large jaw get torn up. I decided to just make some heavy duty ones from scratch. I'm thinking about putting these up for sale if there's some interest.

Finished a set of heavy duty jaws with teeth for a Branch Manager Grapple. We just don't have much luck with the jaws holding up. We love them otherwise. There three of these floating around between mine and a couple of friends that do tree work. Of these three we've had 5 small jaws and one large jaw get torn up. I decided to just make some heavy duty ones from scratch. I'm thinking about putting these up for sale if there's some interest.

I need to do that for mine. If I ever get the time.

I'm interested.It's a swampy mess around here right now. It's frustrating having jobs to do and bills to pay but not being able to work due to the weather. I decided to get some stuff done in the shop until it dries out.

Finished a set of heavy duty jaws with teeth for a Branch Manager Grapple. We just don't have much luck with the jaws holding up. We love them otherwise. There three of these floating around between mine and a couple of friends that do tree work. Of these three we've had 5 small jaws and one large jaw get torn up. I decided to just make some heavy duty ones from scratch. I'm thinking about putting these up for sale if there's some interest.

ChoppyChoppy

Tree Freak

Sick as a dog.

Anybody had problems with chipper blades bending? I pulled the blades off our 15" morbark went to bolt um in the sharpener and noticed the one blade had like a 1/4" cup to it while the other had about 1/8". Both edges (bolt center to cutting edge) were bent like the pic the lines represent the blade ignore the extra material above the blade...

blades are simonds only one maybe two sharpenings on them

blades are simonds only one maybe two sharpenings on them

Sent from my SM-G900T using Tapatalk

Sent from my SM-G900T using Tapatalk

That ain't good. Never seen a blade do that.

Rain day. I still had 8 hours though. 10 trucks all fueled to the max plus 4 chippers and 6 skid loaders. All greased as well. Doing tool inventory sucks when it's not on my truck. Takes way to long. Only thing missing was 1 out of 150 traffic cones and two broken rakes. Not bad for a monthly check

Rain day. I still had 8 hours though. 10 trucks all fueled to the max plus 4 chippers and 6 skid loaders. All greased as well. Doing tool inventory sucks when it's not on my truck. Takes way to long. Only thing missing was 1 out of 150 traffic cones and two broken rakes. Not bad for a monthly check

Were all your hitch pins in place?

Well of course they were. And if they weren't I know where they're kept.

I was just joking. It was a reference to Jeff and his obsession with hitch pins.

Similar threads

- Replies

- 19

- Views

- 1K

- Replies

- 1

- Views

- 246

- Replies

- 0

- Views

- 486

- Replies

- 1

- Views

- 390