You need bias ply tires on those F150's before they become a real truck

...by static pressure dampers you mean the blower blows it open and when it stops the flap falls back shut?

Yes, exactly...

But mine didn't need to be "optimal", the gas furnace is a backup system... honestly, it hasn't run for three or four years now, except for a yearly test run and a couple real cold nights before I installed the latest wood furnace last fall. If my wood furnace was a "supplemental" heating system, rather than "the" heating system, I'd have likely put a bit more thought into design.

Yeah, we use the "front" (forced draft) blower and thermostat... but it doesn't run a lot this time of year. During milder weather it's more about how much, with what, and when you load the thing to keep the house comfortable. It runs more during mid-winter, and makes for fast temperature recoveries. I used a programmable thermostat, so it warms up nicely in the morning, drops back down during midday, warms up a little in the evening, and cools down during sleeping hours. I'm also a bit of a tinkerer; I changed a couple settings and added another sensor so the draft blower doesn't run continuously under demand... it cycles on/off according to firebox temperature (that way it doesn't eat near as much fuel). I rewired the thing for 230-volts and used a large three speed furnace blower for heat circulation... it automatically changes speeds depending on heating demand. To keep the draft blower from running on a cold firebox I wired the thermostat (on the wall upstairs) through a snap switch on the furnace... when the firebox goes cold it cuts power to the thermostat. I added a bypass circuit on a timer switch so I can use the draft blower for start-up on a cold, dead box... I can set that for up to an hour if I want. Finally I put an on/off toggle switch on the draft blower so, if it is running, I can conveniently shut it off during a reload or such.

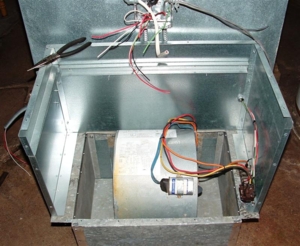

Here's some pictures of the damper I built for the gas furnace...

First I removed the plenum, took measurements, and made a plan... fabrication...

Some final fitting and riveting...

"Flapper" installed with blower off... and blower on...

Reassembly of the plenum... and installation of the 14-inch tie-in duct...

And then I cut the rectangle hole in the top of the wood furnace air jacket, built the plenum for it, and final connection.

If I was to re-do it I'd have made a double or triple "flapper" rather than a single... the single is just a bit heavy.

It works fine as a backup... but if the gas furnace was used often (I even have the gas shut off) I'd want two or three lighter "flappers".

I don't have any pictures of the damper installed on the wood furnace... but it's a real simple affair.

It's just a small aluminum door mounted on the blower housing... it swings up and open when the blower starts, falls back down when it stops.

Both dampers are seated closed "tighter" by static pressure from whichever blower is running.

If you'd like to see more pictures of the total installation here's a link to my "album" where you can scroll through it step-by-step.

http://www.arboristsite.com/community/gallery/photos/263/

*