logicallycompromised

ArboristSite Lurker

hello good sirs or possible misses!

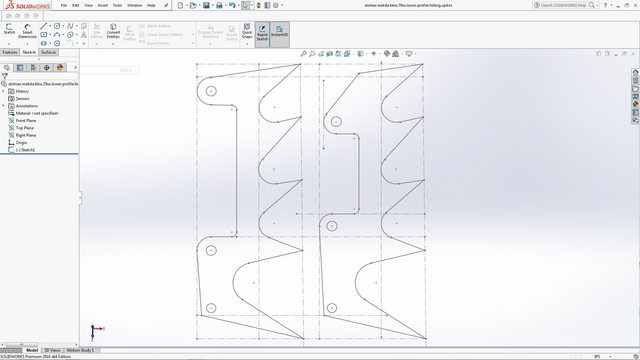

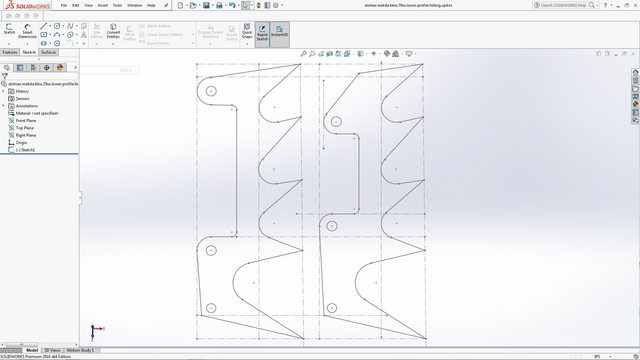

i made some felling spikes a couple weeks ago and found out they were a combination of too thin and too flexible, likely do to cheap steel alloyed with next to zero carbon. well i have put the stock ones back on for the time being and have drawn up a very similar design. the gullet in the lower section is deeper and the three upper teeth aim upwards where as the original design i made had horizontal top edges. i will be heading back to school around the end of the month and plan on making myself a pair of these. once the fitment has been verified i would be happy to cut several more out for others. i would sell them as a set with a roller chain catch. i would like to try and get around 28$ shipped for the kit but will consider and likely yield to the community.

i would like to hear others ideas on the roller catch. the idea i will toss out is...an aluminum bolt provided i can source them locally and then using some sort of plastic as a roller.

as the images will suggest and the caliper confirmed these will be a little more then 1/2" shorter then stock set. they are very similar length on the bottom so that the saw can use them as a point of contact just as the stock ones do.

i imagine within a month or so i will have them on my saw and could have them available to others soon there after that.

i will not hold anyone to it until i have a functional set on my saw but i will use this thread to try and gauge any interest.

the ultimate goal would be to sell enough to take a dent out of the cost of a top handle saw; either tanaka or echo 355t should suit me fine.

i am open to feedback and can alter them to suit the masses if a handful of people agree they prefer another style; e.g. longer spikes in either 4 or 5 tooth versions.

thank you for your time and live long and prosper!

the version i will be moving forward with as of the time of this post.

this image shows the slight offset in the upper mounting ears between the two spikes; the proposed design accounts for this.

they meet their demise when bucking a ~40" ash tree...i was letting the saw slide across to the back side during my top cut so that i could then let her bite in good and feed her all the wood on the far side before returning to the near side and those stumps sitting proud at ~ .040" were just a little to aggressive for the 20f degree ash...lol the lower tooth got all jacked up and here we are.

i made some felling spikes a couple weeks ago and found out they were a combination of too thin and too flexible, likely do to cheap steel alloyed with next to zero carbon. well i have put the stock ones back on for the time being and have drawn up a very similar design. the gullet in the lower section is deeper and the three upper teeth aim upwards where as the original design i made had horizontal top edges. i will be heading back to school around the end of the month and plan on making myself a pair of these. once the fitment has been verified i would be happy to cut several more out for others. i would sell them as a set with a roller chain catch. i would like to try and get around 28$ shipped for the kit but will consider and likely yield to the community.

i would like to hear others ideas on the roller catch. the idea i will toss out is...an aluminum bolt provided i can source them locally and then using some sort of plastic as a roller.

as the images will suggest and the caliper confirmed these will be a little more then 1/2" shorter then stock set. they are very similar length on the bottom so that the saw can use them as a point of contact just as the stock ones do.

i imagine within a month or so i will have them on my saw and could have them available to others soon there after that.

i will not hold anyone to it until i have a functional set on my saw but i will use this thread to try and gauge any interest.

the ultimate goal would be to sell enough to take a dent out of the cost of a top handle saw; either tanaka or echo 355t should suit me fine.

i am open to feedback and can alter them to suit the masses if a handful of people agree they prefer another style; e.g. longer spikes in either 4 or 5 tooth versions.

thank you for your time and live long and prosper!

the version i will be moving forward with as of the time of this post.

this image shows the slight offset in the upper mounting ears between the two spikes; the proposed design accounts for this.

they meet their demise when bucking a ~40" ash tree...i was letting the saw slide across to the back side during my top cut so that i could then let her bite in good and feed her all the wood on the far side before returning to the near side and those stumps sitting proud at ~ .040" were just a little to aggressive for the 20f degree ash...lol the lower tooth got all jacked up and here we are.