Or wear out the PTO side bearing prematurely.And too tight will break a crank.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are these drive links correct for Stihl 361 ?

- Thread starter HansFranz

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Looking at your chain there is issues. The side plates have been riding on the top of the bar and wearing down. The drive links have worn down. I would inspect your bar groves for wear and metal roll over. There is a adjustment on the bottom of the saw to turn up the oiler flow all the way, you most likely have all ready done that.

I think you have been too loose on the chain. As mentioned loose chain can hammer on a sprocket.

Picture of your chain.

Picture of new Stihl RS chain.

Picture of new sprocket

.

I think you have been too loose on the chain. As mentioned loose chain can hammer on a sprocket.

Picture of your chain.

Picture of new Stihl RS chain.

Picture of new sprocket

.

Loose chain hammers the tail of the bar too.

Patrick1903

ArboristSite Operative

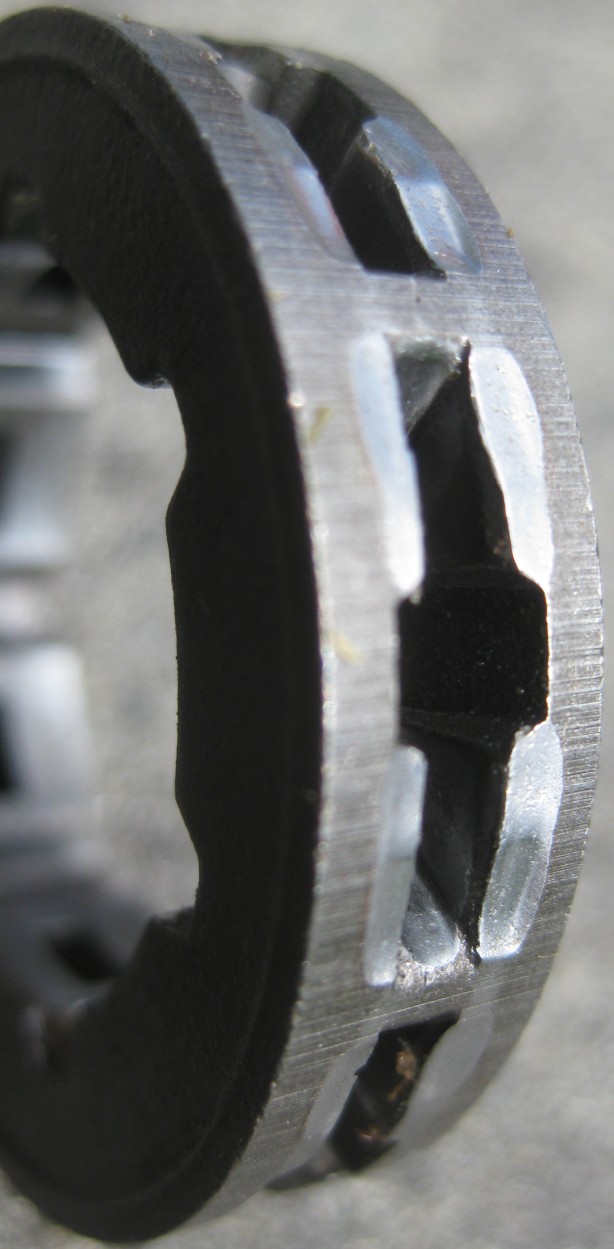

Those sprockets are reversible, right? May want to flip it for the new chain. Not sure how much longer it would make your sprocket last.Here it is ... I'm guessing the divots in the rim on each side of the "holes" shouldn't be there...

I suspect this wear might have something to do with my piss-poor oiler (replaced 2X under warranty and still doesn't oil worth a damn)...one of these days I need to put in a 460 high-volume oiler...

Huh, I had not noticed that but now that you point it out in the photo, it makes sense. Thanks!The side plates have been riding on the top of the bar and wearing down. The drive links have worn down...

.

View attachment 1088192

ETA: The more I unpack this, the more I seem to be getting contradictory ideas:

Question: On a new OEM bar and chain, should the pointy tips of the drive links "bottom out" in the bar groove before the side plates contact the rails?, If so, it seems like the tips (bottoms) of the drive links should either wear down first, or the groove in the bar should be "deepened" by the drive links rubbing against it, before the side plates contact the rails.

On the other hand, if there should be clearance between the pointy tips of the drive links and the bottom of the bar groove, then the side plates should contact the rails right from the get-go, and one or the other (or both) should wear down before the pointy tips of the drive links contact the bottom of the groove.

I've never needed to dress/square/deburr the tops of the rails with a file, so the rails should be close to their original height, minus normal wear.

Question: What do you do when the rails wear down enough (or get filed down enough) that the drive links are rubbing against the bottom of the bar groove? Is there any way to deepen the bar groove? Or will the drive links deepen the bar groove through wear? Or will the drive links wear down because they're softer than the bottom of the bar groove? Now I'm confused

(I keep chains sharp. Dull cutting tools are dangerous.)

The chain is tensioned correctly when it does not sag off the bottom of the bar, you cannot pull a whole driver out of the top groove and you can still pull the chain around by hand. That used chain is beating up the links because it it too loose. Bet the bar also is wearing a divot just behind the top of the nose of the bar from the chain slapping it as it comes around.

Sharp cures many ills. Extra oil will not compensate for a dull chain.

Sharp cures many ills. Extra oil will not compensate for a dull chain.

James Sawyer

ArboristSite Operative

Oregon makes good bars and sprocket! You don't have to buy a Stihl . If you don't have good a source, locally try https://www.madsens1.com/ and https://www.baileysonline.com/ . Lube the Clutch bearing while changing the sprocket before it ruins the crank, you're half way there at that point! It's never a bad idea to have extra rim sprocket, clutch bearing, starter rope, spark plug, fuel filter, and air filter. Your clutch bell is probably going to be stuck I'm betting.

James Sawyer

ArboristSite Operative

oh... and clean the spark arrestor screen.

Thanks, James.Lube the Clutch bearing while changing the sprocket before it ruins the crank, you're half way there at that point!

I grabbed a screenshot from a Youtube video of a guy working on a MS250 showing a needle bearing under the clutch bell:

Is that the bearing you're referring to, that I should lubricate? I guess use grease? (I have a few different types of grease...would black moly grease be OK?)

Thanks again for all the help guys.

James Sawyer

ArboristSite Operative

Yes that's the bearing! The bearing only spins when the saw is idling not when you're cutting, the clutch locks up when chain starts to turn. I use a water proof wheel bearing grease. Just a very light coat of grease just enough to lube the bearing, you don't want the grease to migrate into the clutch.

I assume that saw has an adjustable oiler..

Yep, the OEM did, as well as the two oilers that were replaced under warranty. I gave up after that.I assume that saw has an adjustable oiler..

It stihl doesn't oil worth a crap, though it does deliver enough to prevent burning the bar...in the winter I sometimes thin the oil with kero or ATF.

Patrick1903

ArboristSite Operative

Is it not showing good oil output with bar off the saw?Yep, the OEM did, as well as the two oilers that were replaced under warranty. I gave up after that.

It stihl doesn't oil worth a crap, though it does deliver enough to prevent burning the bar...in the winter I sometimes thin the oil with kero or ATF.

I'm not sure I've ever checked, TBH. Is it OK to spin up a chainsaw with no B&C installed? For some reason I thought that was a no-no.Is it not showing good oil output with bar off the saw?

Whatever the case, the dealer returned it to me -- twice, with two new pumps -- and it never oiled right, even turned all the way up.

On the other hand, my Chinese 660 needs Depends, even with it turned all the way down.

The good news is, thanks to all of your replies, I've given the 361 some 15-year maintenance! Greased the clutch needle bearing, flopped the rim sprocket ... if I keep going, I'll have the thing not running before you know it.

Thanks a lot, everyone. I really appreciate all your help.

Similar threads

- Replies

- 3

- Views

- 705