jar944

ArboristSite Operative

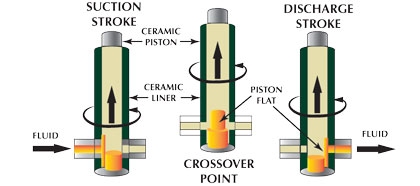

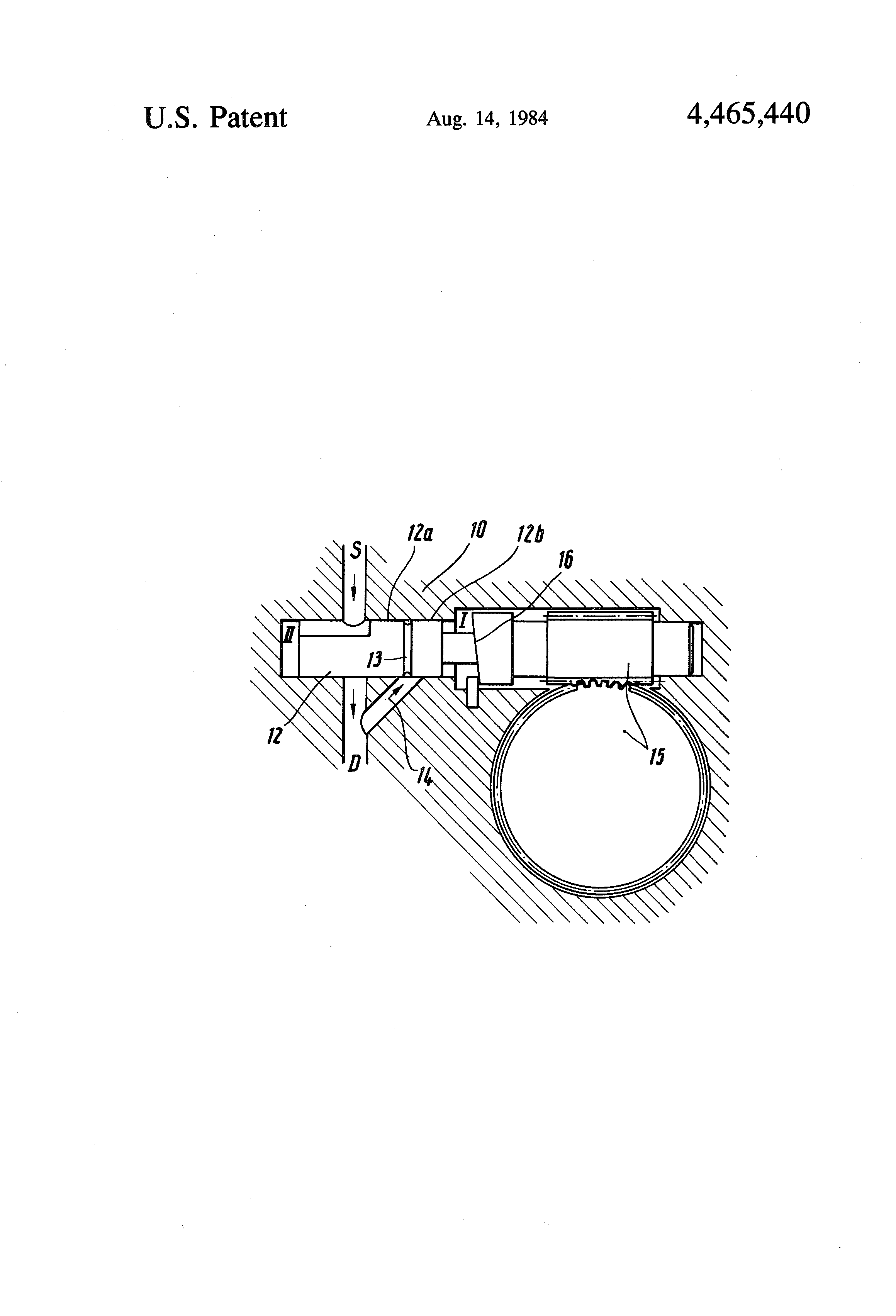

For anyone still following, The plunger/rotor/spurgear is both the piston and the valve for the pump. The flow control screw actually changes the flow by altering the opening/closing timing of the ports. By changing the location of the pin (turning the adjuster) It shortens the time the intake port is open during the charging portion of the "stroke"

Moving the pin more toward center (as the black adjuster does) reduces the total stroke and displacement of the pump

There is a limit to how much stroke the pump body will allow. Interference with the top screw/spring assembly, (the spur gear hits past a certain point), Too much angle could leave the ports uncovered at the wrong time. The last potential issue is that the steeper the angle the higher the shear load on the adjusting screw pin.

Moving the pin more toward center (as the black adjuster does) reduces the total stroke and displacement of the pump

There is a limit to how much stroke the pump body will allow. Interference with the top screw/spring assembly, (the spur gear hits past a certain point), Too much angle could leave the ports uncovered at the wrong time. The last potential issue is that the steeper the angle the higher the shear load on the adjusting screw pin.