You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Safe rope use to guide a falling tree.

- Thread starter sgbotsford

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Gotta admit I have been extremely lucky when winching trees over but to be honest I was just adding a little extra pull to one side so all my trees to date knock on wood I’ve fallen exactly where I wanted them. my real concern is and always will be a tree that is rotten in the middle and barber chairs on me that’s what really scares the snot out of me. Pros make it look easy but in reality it probably the most dangerous thing to do on a day to day basis

i got a more power puller that has worked great so far. If a tree isn't leaning in the direction i need it to fall It gets a rope and usually the more power puller. I got the monster straps to attach to anchor tree. i've gotten pretty good at getting the trees to land where they are supposed to.

I have a bunch of tall poplar that are nearing end of life, and are leaning the wrong way to fell normally without putting house, barn, or shed at risk.

Check my calculations:

A 2 foot diameter poplar with have a stump area about 3 square feet. 80 feet tall. Let's assume that the branches make up for the trunk taper and for weight purposes it is a cylinder. 240 cubic feet.

Wet poplar at 40 lbs/cuft gives me a mass of 9600 pounds -- about 5 tons

If it leans 15 degrees, (over estimate) then there is about 25% of that load is in the horizontal direction. 2400 lbs.

I have 150' 3/4" nylon solid braid) rope with a rated breaking strength of 20,000 pounds in new condition, with an eye splice on either end.

My thought is put a messenger line into the crown, draw the rope up and over, bring the eye down, and pass thorugh. Attach the other end to my tractor (Deuzt 55 hp -- weighs about 3 tons)

Coefficient of friction on a tractor tire on firm soil is aobut .5 So maximum force tractor can put on rope is about 3000 lbs.

So use the tractor to tension the rope until wheels start to skid, OR it stretches 8% (Estimate of elastic stretch. I have an inquiry with the rope maker for this number)

My plan was to make the wedge cut first, then tension the rope, then make the back cut.

Is this a reasonable approach?

I haven't checked all your math, but I'm pretty sure that the branches do far more than make up for the taper. It is startling how much more the leaves and twigs weigh when compared to the mass of the branch that supports them. Furthermore, the distance they are displaced from the centerline makes a huge difference.

I agree with others that you are planning on pulling way too hard.

I think there are a lot of things you haven't considered. I'll just mention a few.

- I think 5 tons is considerably light for an 80' tall poplar. BTW: how did you measure that height?

- The higher you attach your rope, the weaker the wood will be. Poplar breaks real easy, by the way. You are likely to break the crown out if you put it too high and pull too hard.

- The higher you hang your rope on the tree, the more weight you will take off your tractor, especially if you attach to the rear drawbar. Traction will be reduced! Where you tie to the tractor can dramatically affect what happens when you pop the clutch as the chainsaw operator hollers "Go!"

- How are you going to tie on to the tractor? I've seen many a rope broken wrapped around hard steel.

- What knot can you tie in nylon rope that won't weaken the rope or even fuse under pressure? (Nylon is famous for doing that, you know)

- The amount of torque you need when attaching high in the tree is difficult to calculate. Even though the tree is pitched at perhaps 15° off-center, how much weight are you actually lifting when you pull the tree against the lean? You are practically at the tangent to the arc of the crown's travel downward, and pulling sideways against gravity doesn't take that much force. It certainly isn't equal to the weight of the tree, 'cause you have a lot of leverage.

Then put a really good tug on the tree and rope, just to see how it all acts before you need to worry about the tree actually falling. You should be able to gently sway the tree with your rope & tractor prior to ever starting the saw. If it's going to break out the crown, the best time to find out is when no one is standing at the bottom.

Now loosen the load on the rope, and have the operator put just enough tension on it to make the rope "not loose".

Then make a good face cut of about 1/3 diameter, and move around to the back cut. As you make your back cut, watch VERY carefully for the tree to begin settling on the saw. When you detect that the gap is closing, have your tractor operator slowly advance his tension until the tree is no longer settling on the cut. At this point, you are fairly assured of having everything in balance, and you can proceed through the back cut until you think it is safe for the tractor to pull the tree over.

Obviously, this is a risky operation, and depends upon having the experience of knowing how to make the cuts, how to set the rope, and how to pull it with the tractor. But that's how I would do it, and I have pulled a lot of trees over with a tractor.

A last caveat: heavy leaners often fall sideways when pulled over by a tractor. A little breeze, an imbalance in the tree, the feller cuts the hinge too thin... Plop! The damned tree went sideways, because the tractor was going too slow.

Be careful. When your tractor has the tree going his way, that's the wrong time to go slow.

I thought there was a few great disscutions that a could have added to before I left the thread. May get back to some of them today.

I was meaning to correct my math disaster from the next day after my first post of the thread but didn't get around to it. I apologize to the OP if he was to chech back in. I misinterpreted what he wrote (Did) and then did it wrong myself.

As Timber Fallers, we do the math in our head and average the log measurements to get a rough estimate. Close enough to get a rough volume if the ends are not too different and then just minus 20% for the curvature.

Certainly did not work on a true cone shape. Put me out 50%.

Properly, they would calculate face area on both ends and cone you just half the butt cu ft then times by ' length.

I was meaning to correct my math disaster from the next day after my first post of the thread but didn't get around to it. I apologize to the OP if he was to chech back in. I misinterpreted what he wrote (Did) and then did it wrong myself.

As Timber Fallers, we do the math in our head and average the log measurements to get a rough estimate. Close enough to get a rough volume if the ends are not too different and then just minus 20% for the curvature.

Certainly did not work on a true cone shape. Put me out 50%.

Properly, they would calculate face area on both ends and cone you just half the butt cu ft then times by ' length.

Thought it was a beaver tree. I have seen chicken wire around big cottonwood in the BC interior parts of the Fraser. Cottonwood is not big on the menu in west Canada. They seem to love the Aspen of the interior though.With a few wedges and a tag on the opposite side it fell where I wanted it too. Beavers been chomping on it for 15 years thats why the base looks like that.

Looks like a certified beaver though.

Certified beaver goes around the tree and takes out all the live cell sapwood..which is the strongest wood and where barber chairs happen. May be a lesson to us in there somewhere.

They say a lazy beaver has long curly teeth.

A thought a lazy beaver had coarse blonde hair and lives in the bed.

Ok , must be a bad Canadian joke.

Glad the tree went well for you.

Fell a hand full of beaver trees just hanging on a thread.

Instead of a support line you can do a "Jonny hold me right " a channel cut. I use a conventional felling cut then cut out three slim plates each no fatter than chain width then snap the plate with bar by twisting handle up. Make sure the back face is 90° or you are defeating the purpose. This should gives you about 1 1/2 to 2" of vertical face in the back to peel down and hold on much longer.

Sometimes I do it with a bore cut and start with the bore cut first. In small trees you can get away with the 4" bore and 2 flat cuts to match the 2 back corners to complete the channel. You can still aim.. get behind sight lines and put tip against the tree then just imagine top over the distance from sight line to centre of tree.. when the tree is growing straight.

On bigger trees you can just do the bore..2 flat cuts and a modified Swanson out of the front cut (a sharp angle out of the bottom to delay the cut closing and let the butt slip to grownd quicker.)

Lots of wedges. That's good.

Lots of the right wedges and a little hammer will serve you better than a bigger one and 1 fat wedge

That's alot of knowledge and experience in that post. I will save it for future reference. Thanks! There's a beaver on our property that has been gnawing on big cottonwood trees along the river edge. He must have messed up teeth he even tried gnawing the bark off a 4" beech. He never took a tree down yet that I could see. I tried to do the beaver a favor and left the top 40-50' of the tree in the bottomland/floodplain for him to snack on. He didn't take any branches but he cleaned quite a few of them bare of bark. I keep the 'how to fell a tree' book by Jeff jepson with me wherever I go just incase I need to double check what I am doing.

newbomb

ArboristSite Lurker

Time to apply some physics here.

I have been falling some 15+ year old poplars which are up to about 20" in diameter and about 90' tall. Many of them are leaning toward the neighbor's house at up to 7 degrees (I doubt the OP's lean is > 10, and if it is I would have second thoughts). Get an inclinometer. These trees would also hit my house if I 'missed'.

One can easily calculate the needed 'force' to prevent the tree from moving (i.e. pull it back over). Let's provide an example with some real data. See diagram in tree.jpg.

We calculate the moment about the holding wood using the tree mass and a 5/16" chain pulling at only 25' up the tree straight out (I'll correct for this later).

Using extremely conservative values:

- Assuming 18" tree is a perfect cylinder 80' tall.

- Mass, using density of 47 lbs/ft^3 (which was measured with a real chunk of wood) is 6700 lbs (3000 kg).

- Force needed on chain for 7 degree lean is calculated at 5781 N, or 589 kg.

- Force needed with chain angle to ground is 604 kg, or 1331 lb.

- Again, this calculation is very conservative, and I expect less than 1000 lb. is needed.

I just fell one of these trees using a 5/16" chain attached at 25' height pulling with my JD2305. Tractor weight (bare) is ~1500 lbs, but I have extra weight (loader, etc.) of about 1200 lbs. so I am at ~ 2700 lbs.

25' is very low, but it still does not approach the shear strength of the holding wood as long as the lean is not enough to overcome holding wood elasticity. Roughly, poplar/cottonwood has a shear strength of 600-700 psi, so unless you cut your holding wood down to a measly 2 in^2, it will hold. This is yet another reason why a 10+ degree lean is dicey.

If one is to attach a rope at 40', the force needed drops considerably: 811 lbs. At 60': 540 lbs.

Point is this can be done safely if you think about it:

- Cut your notch exact

- Use a large tri-square to verify the fall line by putting it in the notch

- (See picture and tractor in background which was exact intended direction)

- Strap the tree so it won't barber chair on you (see picture)

- The notch cut will have more bearing on the fall direction when pulling it down (not the back cut)

- Don't pull hard until the back cut is almost complete

- You will get some pull-out on the holding wood, but that is OK.

I have 9 trees down and 13 more to go. At $900 per tree for a pro to do it, I am doing OK.

~T

I have been falling some 15+ year old poplars which are up to about 20" in diameter and about 90' tall. Many of them are leaning toward the neighbor's house at up to 7 degrees (I doubt the OP's lean is > 10, and if it is I would have second thoughts). Get an inclinometer. These trees would also hit my house if I 'missed'.

One can easily calculate the needed 'force' to prevent the tree from moving (i.e. pull it back over). Let's provide an example with some real data. See diagram in tree.jpg.

We calculate the moment about the holding wood using the tree mass and a 5/16" chain pulling at only 25' up the tree straight out (I'll correct for this later).

Using extremely conservative values:

- Assuming 18" tree is a perfect cylinder 80' tall.

- Mass, using density of 47 lbs/ft^3 (which was measured with a real chunk of wood) is 6700 lbs (3000 kg).

- Force needed on chain for 7 degree lean is calculated at 5781 N, or 589 kg.

- Force needed with chain angle to ground is 604 kg, or 1331 lb.

- Again, this calculation is very conservative, and I expect less than 1000 lb. is needed.

I just fell one of these trees using a 5/16" chain attached at 25' height pulling with my JD2305. Tractor weight (bare) is ~1500 lbs, but I have extra weight (loader, etc.) of about 1200 lbs. so I am at ~ 2700 lbs.

25' is very low, but it still does not approach the shear strength of the holding wood as long as the lean is not enough to overcome holding wood elasticity. Roughly, poplar/cottonwood has a shear strength of 600-700 psi, so unless you cut your holding wood down to a measly 2 in^2, it will hold. This is yet another reason why a 10+ degree lean is dicey.

If one is to attach a rope at 40', the force needed drops considerably: 811 lbs. At 60': 540 lbs.

Point is this can be done safely if you think about it:

- Cut your notch exact

- Use a large tri-square to verify the fall line by putting it in the notch

- (See picture and tractor in background which was exact intended direction)

- Strap the tree so it won't barber chair on you (see picture)

- The notch cut will have more bearing on the fall direction when pulling it down (not the back cut)

- Don't pull hard until the back cut is almost complete

- You will get some pull-out on the holding wood, but that is OK.

I have 9 trees down and 13 more to go. At $900 per tree for a pro to do it, I am doing OK.

~T

Attachments

Your math looks good. Just two observations, raise your backcut and your hinge will work better with less tearout, and no need to use a square, just use the sight line on your saw.Time to apply some physics here.

I have been falling some 15+ year old poplars which are up to about 20" in diameter and about 90' tall. Many of them are leaning toward the neighbor's house at up to 7 degrees (I doubt the OP's lean is > 10, and if it is I would have second thoughts). Get an inclinometer. These trees would also hit my house if I 'missed'.

One can easily calculate the needed 'force' to prevent the tree from moving (i.e. pull it back over). Let's provide an example with some real data. See diagram in tree.jpg.

We calculate the moment about the holding wood using the tree mass and a 5/16" chain pulling at only 25' up the tree straight out (I'll correct for this later).

Using extremely conservative values:

- Assuming 18" tree is a perfect cylinder 80' tall.

- Mass, using density of 47 lbs/ft^3 (which was measured with a real chunk of wood) is 6700 lbs (3000 kg).

- Force needed on chain for 7 degree lean is calculated at 5781 N, or 589 kg.

- Force needed with chain angle to ground is 604 kg, or 1331 lb.

- Again, this calculation is very conservative, and I expect less than 1000 lb. is needed.

I just fell one of these trees using a 5/16" chain attached at 25' height pulling with my JD2305. Tractor weight (bare) is ~1500 lbs, but I have extra weight (loader, etc.) of about 1200 lbs. so I am at ~ 2700 lbs.

25' is very low, but it still does not approach the shear strength of the holding wood as long as the lean is not enough to overcome holding wood elasticity. Roughly, poplar/cottonwood has a shear strength of 600-700 psi, so unless you cut your holding wood down to a measly 2 in^2, it will hold. This is yet another reason why a 10+ degree lean is dicey.

If one is to attach a rope at 40', the force needed drops considerably: 811 lbs. At 60': 540 lbs.

Point is this can be done safely if you think about it:

- Cut your notch exact

- Use a large tri-square to verify the fall line by putting it in the notch

- (See picture and tractor in background which was exact intended direction)

- Strap the tree so it won't barber chair on you (see picture)

- The notch cut will have more bearing on the fall direction when pulling it down (not the back cut)

- Don't pull hard until the back cut is almost complete

- You will get some pull-out on the holding wood, but that is OK.

I have 9 trees down and 13 more to go. At $900 per tree for a pro to do it, I am doing OK.

~T

newbomb

ArboristSite Lurker

Thanks for the input.Your math looks good. Just two observations, raise your backcut and your hinge will work better with less tearout, and no need to use a square, just use the sight line on your saw.

It's hard to tell from the picture but the back cut on that stump is a good two inches above. I use the tri-square as a second check. Some of these trees have to go exactly where I want or I'm going to hit something that will cause damage. Tri square gives me an exact line.

Attachments

So does your saw, that's what the black line is for.Thanks for the input.

It's hard to tell from the picture but the back cut on that stump is a good two inches above. I use the tri-square as a second check. Some of these trees have to go exactly where I want or I'm going to hit something that will cause damage. Tri square gives me an exact line.

Wow, just wow. Can't believe all the different comments on this thread.

As for the original question. Use a arborist bull rope rated for the weight of the pull or better. I have a 3/4" with a rated breaking at 23000lb. Never a issue. 2nd piece of advise. Never cut problem trees when it is windy. 3rd use common sense and experience. If you are lacking the latter find someone to help you. If the first hire someone and sell the saw.

In the multiple thousands of trees I have dropped I have only had 1 barber chair. It was a 50" + oak leaning into a farmers field at about 15 degrees with a 10"+ widowmaker just above my head. I chickened out and did not finish the cut as it was falling. I only had my 372 as this was just supposed to be a firewood trip. I have done 0 dollars worth of damage to anyone's property and yes I have insurance. I use at least 2 tie off points, 1 pulling and 1 for the what if moment. Normally just use the tractor, stand it up against the tree off the ground and the weight pushes it over. The majority of my cutting is done by myself. Unless it is a problem tree then you will always have a audience! Remember, things are replaceable you are NOT. Cj

As for the original question. Use a arborist bull rope rated for the weight of the pull or better. I have a 3/4" with a rated breaking at 23000lb. Never a issue. 2nd piece of advise. Never cut problem trees when it is windy. 3rd use common sense and experience. If you are lacking the latter find someone to help you. If the first hire someone and sell the saw.

In the multiple thousands of trees I have dropped I have only had 1 barber chair. It was a 50" + oak leaning into a farmers field at about 15 degrees with a 10"+ widowmaker just above my head. I chickened out and did not finish the cut as it was falling. I only had my 372 as this was just supposed to be a firewood trip. I have done 0 dollars worth of damage to anyone's property and yes I have insurance. I use at least 2 tie off points, 1 pulling and 1 for the what if moment. Normally just use the tractor, stand it up against the tree off the ground and the weight pushes it over. The majority of my cutting is done by myself. Unless it is a problem tree then you will always have a audience! Remember, things are replaceable you are NOT. Cj

You said neverNever cut problem trees when it is windy.

I often wait until it's windy to cut problem trees.

That's the problem with giving advice on the net, you're not there and it's difficult to transfer your experience in a book let alone a couple paragraphs.

Yea, me too unless it is near a home. It is hard to tell someone how to use the wind when it stops in mid cut!! CJYou said never.

I often wait until it's windy to cut problem trees.

That's the problem with giving advice on the net, you're not there and it's difficult to transfer your experience in a book let alone a couple paragraphs.

To many rules for ropes.

One rule. Make sure you are 100% in what you do

One rule. Make sure you are 100% in what you do

That cut looks interestingThanks for the input.

It's hard to tell from the picture but the back cut on that stump is a good two inches above. I use the tri-square as a second check. Some of these trees have to go exactly where I want or I'm going to hit something that will cause damage. Tri square gives me an exact line.

Dangerous

ArboristSite Lurker

When I cut trees the wind direction and intensity are determining factors what tree get felled that day.You said never.

I often wait until it's windy to cut problem trees.

That's the problem with giving advice on the net, you're not there and it's difficult to transfer your experience in a book let alone a couple paragraphs.

D

Poplar not best hinging wood; but in general...

Have the inline to fall, squared to face, across narrow part of hinge as aligned axis(cos)

>>then the cross-axis along the length of hinge(sine)

Would use rope, and then tap wedge as anti sitback/safety.

.

Would not look to bull dawg to ground, with tractor full force, but use much more finesse than METERED force.

PLEASE, are looking to tip scales to lightly flow correctly, not break scales..

>>for one thing as load system with tractor pull, that is then a greater loaded power axis

>>and if something (rope) overloads as fuse, can even fold backwards like standing behind breach end of rocket launcher

.

Can instead look to force stronger hinge with fake load of forward pull

>>since hinge thickness as a strength is a response to pulls on that axis

Then alter shape of hinge to Tapered Hinge

>>fat side to counter(what Dent's manual calls off-side) the side lean as a ballast against the side lean(removing side lean from equation more)

>>so then the fall only reveals the forward force on target axis (assuming NOT backleaner)

.

Also note compressed part of hinge is pivot, so some of the force leaning towards target, some away on that inline to face axis

>>so partially depends on how much hinge as pivot undermines the CoG as force

But for sideleans favor greatest breadth of hinge across generally at center of tree

>>as reach for to undermine CoG more, past the center risks less sideLean control in trade then..

>>only need to convince the part on the far side of hinge pivot to go home to target

>> which is automatic if Center of Gravity(CoG) is past the pivot,

>>but still best to give some pull to thicker hinge, especially if try to use Tapered Hinge, to empower it more.

Force hinge stronger as if rope pull is 80# backpack to exercise stronger

>>then rope goes slack as fall starts and now have fatter exercised hinge with less leveraged load on it.

.

Would look to place rope at side to side balanced position for balanced pull

>>above CoG to take leverage over it, but gripping firm rigidity of spar

>>no wind, for even friendly wind can shift

And have overwhelming force available, but w/bear force be Gentle Ben of only judiciously metering force from force pool, not running scared with it overloading the circuit.

This is a feel, as well as an understanding.

Really, should get enough leverage higher than CoG that 2 men can effect properly, if not then 3/1 pulley(rolling levers) jig as input for them against tree.

>>so scared tractor use is serious overload of force

.

.

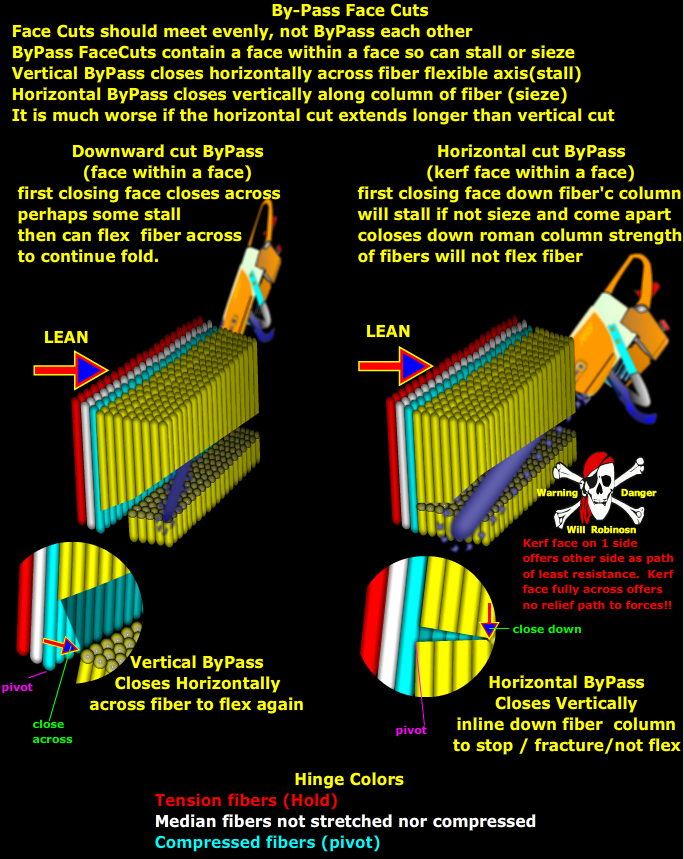

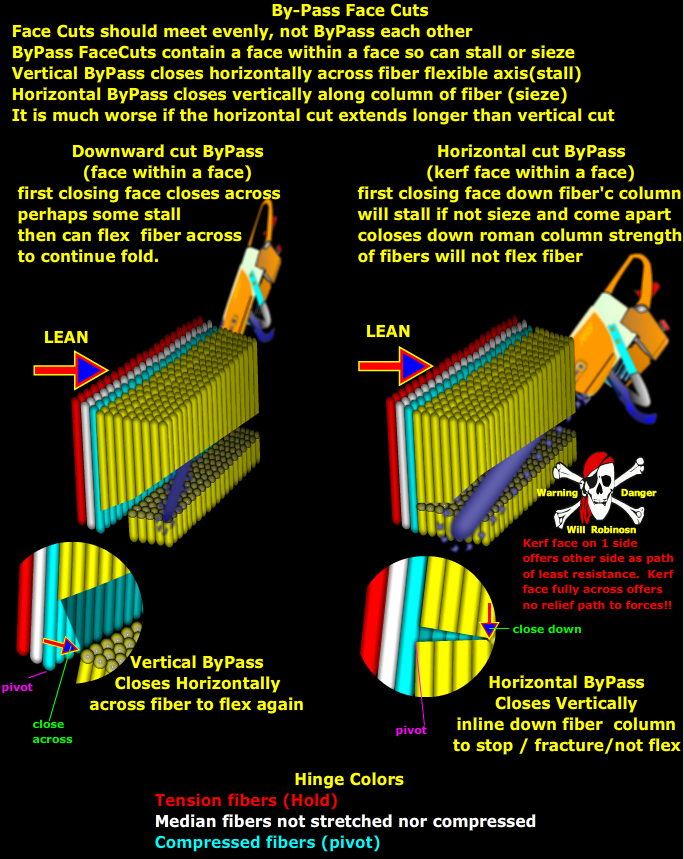

BarberChair is from too slow of fall or closing too early in face(or mix of both)

>>especially in brittle wood....

Closing of face too early can happen across breath of face especially if slant and horizontal cut not machined square

>>you do NOT want to create a face within a face that internal /ruling face closes very early

>>not much speed and not much lean as factors to not be committed to fall and fail instead of throw cleanly thru riskiest part of fall.

Fail can be from a fight that overrules the constitution of the spar as a container

>>of part of tree needing to rush forward and dead stop of that close in face, getting a split decision /BC.

>>2 bad azzes in the ring, neither ever been beat, neither giving up any ground and at matched stall against each other, something has to give and it can be the tree itself.

If specifically allow the horizontal cut to bypass the slanted can get the close vertically on the vertical fiber columns for a dead stop !!

Classic: The Fundamentals of General Tree Work by G.F. Beranek /hosted by Educated Climber.com

Great: Tree_Felling_Presentation.pdf

Article: Tree Care Industry: Greater Falling Accuracy Using the Tapered Hinge

Mini course: COURSE IN REDUCED-IMPACT LOGGING: Chainsaw Use, Safety Practices & Directional Tree Felling Techniques

YouTube: Tree Felling Don't Become a Statistic (~8.30 in felling cuts)

from Previous Thread:standard-rectangular-strip-vs-tapered-triangular-hinge-when-sidelean

VERY counter-intuitively look at sideLean managed by hinge,

and rope pull not against sideLean really (at all except in extreme); as so much forward to force hinge stronger

>>think of model of pulling to side some against side lean babying hinge weaker

>>then as rope goes slack that side load that was relieved jumps back with impact possibly.

Look at as if to NOT work rope to make better hinge to then run show

>>is leaving hinge multiplier out of the multiplier chain....

The geometric shape change of the hinge would be more correct against side load in any material

>>Tapered hinge even works in tree, fat end up against gravity to get more horizontal sweep sideways off house, into rig etc. from more horizontal limbs.

>>Even some in bucking, all are same model at different angles, but SAME angle against the side force to target in all....

Have the inline to fall, squared to face, across narrow part of hinge as aligned axis(cos)

>>then the cross-axis along the length of hinge(sine)

Would use rope, and then tap wedge as anti sitback/safety.

.

Would not look to bull dawg to ground, with tractor full force, but use much more finesse than METERED force.

PLEASE, are looking to tip scales to lightly flow correctly, not break scales..

>>for one thing as load system with tractor pull, that is then a greater loaded power axis

>>and if something (rope) overloads as fuse, can even fold backwards like standing behind breach end of rocket launcher

.

Can instead look to force stronger hinge with fake load of forward pull

>>since hinge thickness as a strength is a response to pulls on that axis

Then alter shape of hinge to Tapered Hinge

>>fat side to counter(what Dent's manual calls off-side) the side lean as a ballast against the side lean(removing side lean from equation more)

>>so then the fall only reveals the forward force on target axis (assuming NOT backleaner)

.

Also note compressed part of hinge is pivot, so some of the force leaning towards target, some away on that inline to face axis

>>so partially depends on how much hinge as pivot undermines the CoG as force

But for sideleans favor greatest breadth of hinge across generally at center of tree

>>as reach for to undermine CoG more, past the center risks less sideLean control in trade then..

>>only need to convince the part on the far side of hinge pivot to go home to target

>> which is automatic if Center of Gravity(CoG) is past the pivot,

>>but still best to give some pull to thicker hinge, especially if try to use Tapered Hinge, to empower it more.

Force hinge stronger as if rope pull is 80# backpack to exercise stronger

>>then rope goes slack as fall starts and now have fatter exercised hinge with less leveraged load on it.

.

Would look to place rope at side to side balanced position for balanced pull

>>above CoG to take leverage over it, but gripping firm rigidity of spar

>>no wind, for even friendly wind can shift

And have overwhelming force available, but w/bear force be Gentle Ben of only judiciously metering force from force pool, not running scared with it overloading the circuit.

This is a feel, as well as an understanding.

Really, should get enough leverage higher than CoG that 2 men can effect properly, if not then 3/1 pulley(rolling levers) jig as input for them against tree.

>>so scared tractor use is serious overload of force

.

.

BarberChair is from too slow of fall or closing too early in face(or mix of both)

>>especially in brittle wood....

Closing of face too early can happen across breath of face especially if slant and horizontal cut not machined square

>>you do NOT want to create a face within a face that internal /ruling face closes very early

>>not much speed and not much lean as factors to not be committed to fall and fail instead of throw cleanly thru riskiest part of fall.

Fail can be from a fight that overrules the constitution of the spar as a container

>>of part of tree needing to rush forward and dead stop of that close in face, getting a split decision /BC.

>>2 bad azzes in the ring, neither ever been beat, neither giving up any ground and at matched stall against each other, something has to give and it can be the tree itself.

If specifically allow the horizontal cut to bypass the slanted can get the close vertically on the vertical fiber columns for a dead stop !!

Classic: The Fundamentals of General Tree Work by G.F. Beranek /hosted by Educated Climber.com

Great: Tree_Felling_Presentation.pdf

Article: Tree Care Industry: Greater Falling Accuracy Using the Tapered Hinge

Mini course: COURSE IN REDUCED-IMPACT LOGGING: Chainsaw Use, Safety Practices & Directional Tree Felling Techniques

YouTube: Tree Felling Don't Become a Statistic (~8.30 in felling cuts)

from Previous Thread:standard-rectangular-strip-vs-tapered-triangular-hinge-when-sidelean

VERY counter-intuitively look at sideLean managed by hinge,

and rope pull not against sideLean really (at all except in extreme); as so much forward to force hinge stronger

>>think of model of pulling to side some against side lean babying hinge weaker

>>then as rope goes slack that side load that was relieved jumps back with impact possibly.

Look at as if to NOT work rope to make better hinge to then run show

>>is leaving hinge multiplier out of the multiplier chain....

The geometric shape change of the hinge would be more correct against side load in any material

>>Tapered hinge even works in tree, fat end up against gravity to get more horizontal sweep sideways off house, into rig etc. from more horizontal limbs.

>>Even some in bucking, all are same model at different angles, but SAME angle against the side force to target in all....

Lucky to be alive with that one. If in fact nothing happened, almost looks like he ran into the tree falling, tree went 3 different ways probably not sure where to go on that one in regards to escape route

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 47

- Views

- 7K

- Replies

- 81

- Views

- 3K