My cousin's 029 had the spark plug blow out and strip the plug threads completely out. We started taking it apart so as to install a new cylinder kit. The cylinder bolts were very TIGHT and we got three of the four out BUT the last one which is the deepest one into the plastic case had the torx head on the tool break off in the bolt head. WOW, never thought I would see that but it happened. We now are baffled as to how to remove this last cylinder bolt and we have tried drilling it BUT this thing appears to be made of concrete as we can't get a single drill bit to drill much into it. Anyone have any ideas as my cousin went and bought a cobalt drill bit yesterday and it merely spun on top of what little drilling we have got into the bold head. We do have the cylinder and plastic housing on a drill press but so far we can't make much of a dent into the bold head. Sure hate to tear up the plastic housing as then replacing it will make the repair cost more than the saw is worth. Looking for opinions on how best to proceed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl 029 Super repair problem

- Thread starter wardog

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Updating this post. I bought a used cylinder case, cylinder, piston, muffler and have this 029 put back together. GOOD thing I could get pictures and info from the manual i downloaded. I have NEVER torn into a chainsaw before and didn't even take this one apart, so much of it was foreign to me. What I have found is that the used case seems to have the threads that hold the magneto tight against the flywheel has one that will not tighten down. I never looked them mover prior to mounting everything but when I mounted the mag it would not get tight. I suspect the plastic is striped and my question is what good ways there are to repair this stripped bolt hole? I tried to put blue lock tight on it but that didn't seem to help.

Since it is plastic,, there is not much strength to begin with,,,,,,I suspect the plastic is striped and my question is what good ways there are to repair this stripped bolt hole?

I can not see the location,, so ,, guessing,,

you can normally Heli-coil the plastic, then screw into the Heli-coil.

On some plastics, you can get some similar plastic, then "weld" the hole shut, and start over.

In the case of welding, normally a hot glue gun will do small stuff.

If it is truly low stress,, JB -Weld works in some cases.

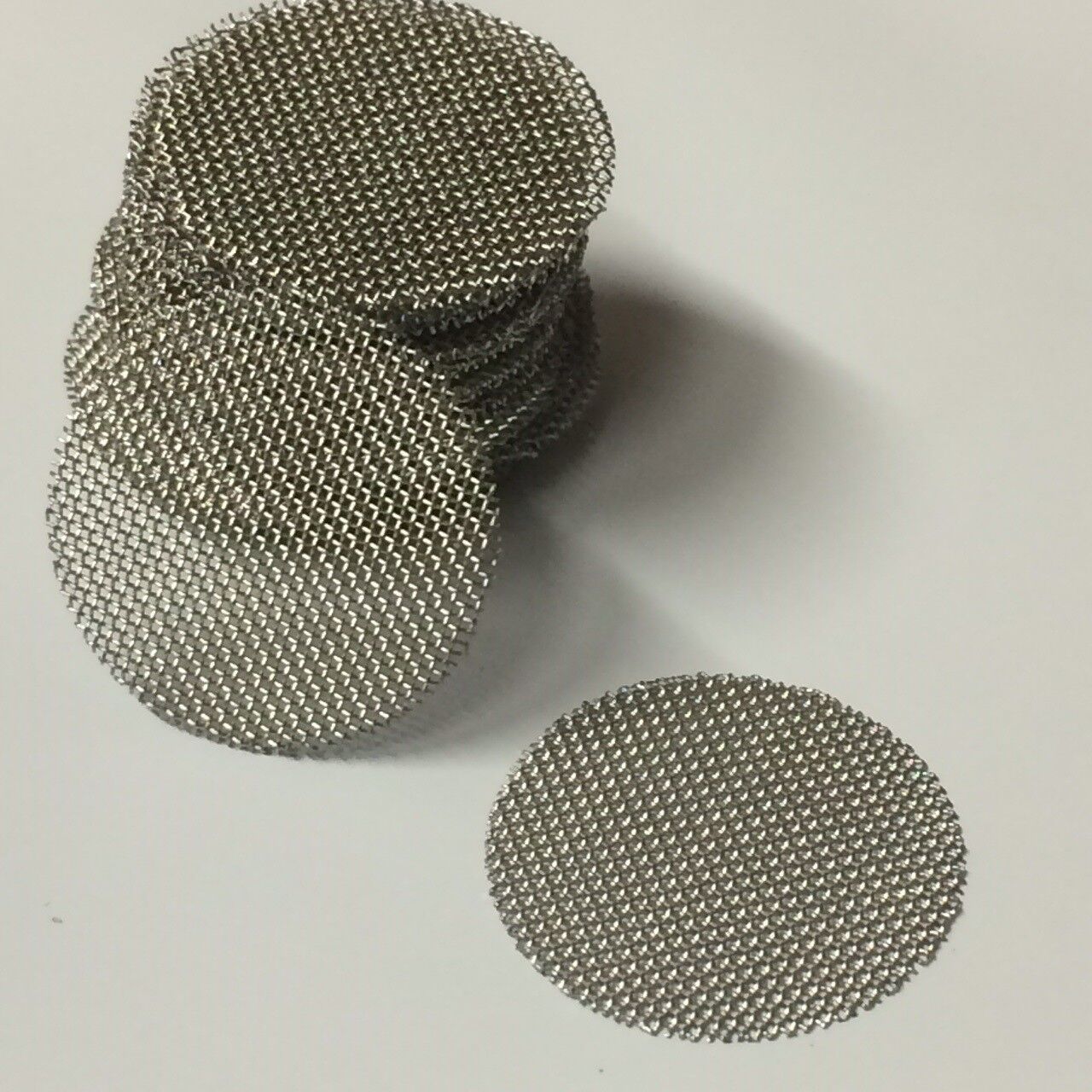

I keep some stainless steel screen JUST for plastic, I even fixed a cracked fuel tank on an ATV with stainless screen.

Cut an appropriate size piece of screen, then "sink" the piece of screen right into the plastic.

Where you want to put a screw in,, fold the screen so that it is double, or triple, then sink the screen into the plastic.

I use a Weller soldering gun to heat the screen, when the screen is hot, it just goes right down into the plastic.

The screw will REALLY hold,, biting into stainless steel screen,,,

If you are just doing a screw hole, stop at a tobacco shop, they sell a small stainless screen,, cheap, usually under a dollar.

With any of these techniques, they are all pretty easy,, so practice on some scrap first,, THEN do the saw.

The hard plastic of the Farm Boss chassis lends itself well to use 5mm Helicoil repair inserts.

I’ve fixed buffer mount holes, starter mount and coil mounts.

You actually end up with a stronger thread.

I’ve fixed buffer mount holes, starter mount and coil mounts.

You actually end up with a stronger thread.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 0

- Views

- 377

Latest posts

-

-

-

-

-

Please recommend a small chipper- Boxer x7 vs Vermeer bc700xl or....

- Latest: clydesdale6

-