Yotaismygame

Juiced Saws #GetJuiced

Sounds like a solid piston swap

Breaking in well

Next project is 066

Heimannm, on the PM6's do you have a hard time getting the tank section (fuel line) to seal up against the carb when you pull the tank/recoil? I have several of them and even using a small amount of teflon lube in order to get the end of the formed fuel line to seat it's a battle at best. I have put in NOS lines and still have one that fights me.

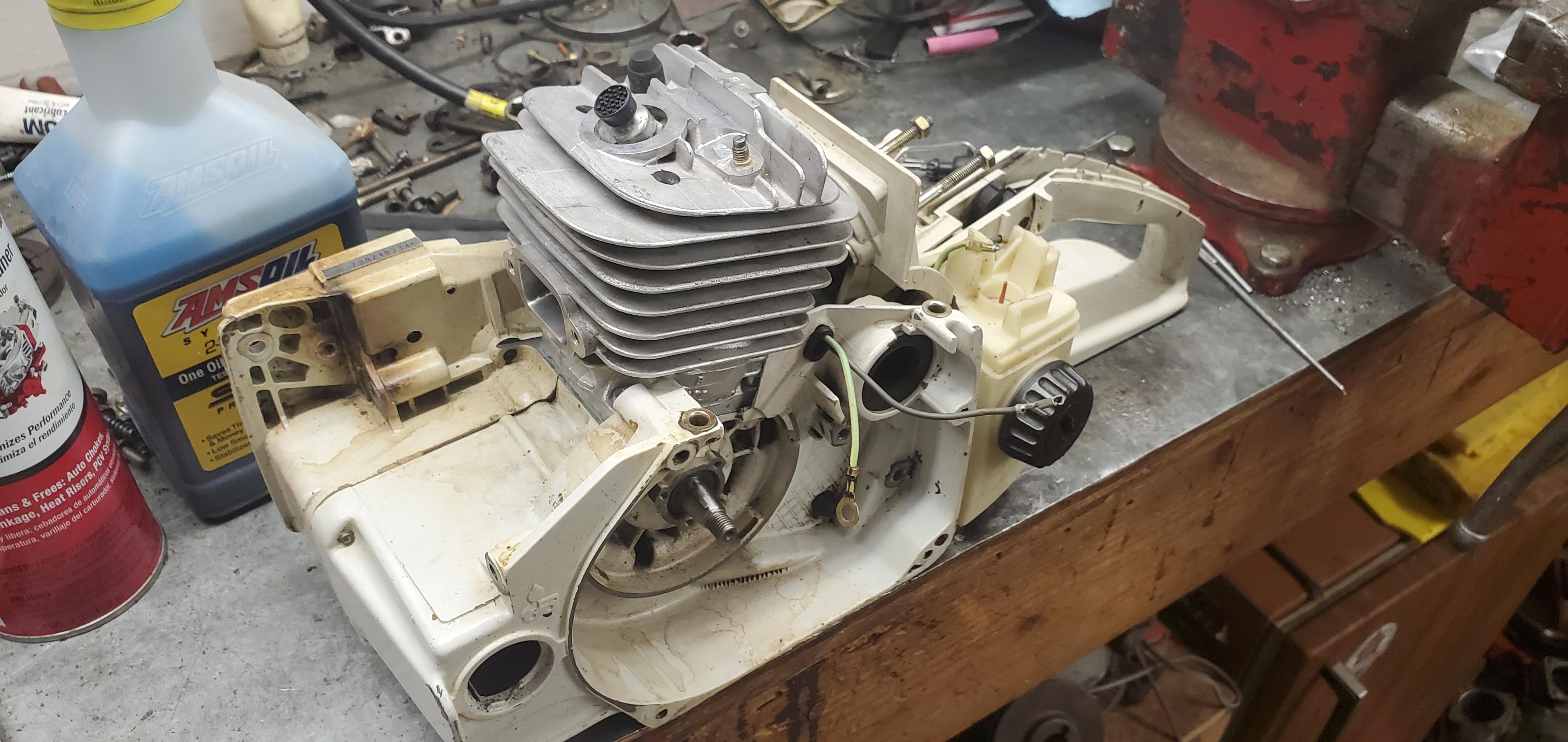

Thank you, I had thought about doing that but was never sure what size O-ring I would need and I will use a buna-n/nitrile O-ring.Here is a photo of the PM6 fuel nipple with a two 007 o-rings in place. this seems to both stretch the nipple and provide a large O.D. to press into the fitting and make a good seal.

View attachment 915236

Mark

Nice Yota, I ordered in a 11" lathe and it will be here towards the end of Aug. I went and looked at a SB10 (not the heavy 10) but it had only a 3/4" pass through on the spindle and a 2MT tail stock, plus the apron clutches where slipping, I could have fixed it but I already have enough projects on my plate so I passed. The lathe I ordered has a 1-1/2" pass through on the spindle and a 3mt tail stock, plus now I can use a larger tool post which will make it a lot easier to hold a 3/4" boring bar for modifying the squish band up in the cylinder where the best I can hold now is a 1/2" that has a lot of flex when stuck out that far.

Very nice looking saw MJ.Homelite super xl 1973, very low hours, first chain, only disassembled and cleaned. Runs like new...oh needed new fuel line.

Enter your email address to join: