Wow- I bet that's heavy. I should dry out quickly though. You got a nice smooth cut. What kind of chain are you running?

Most of the western red cedar I get to cut is dry or almost dry. Some of it is fire salvage so it's a pretty dirty job. I use a draw knife where my next cut will be. On the bottom half of the log I sometimes just chalk a line and cut off a piece with my skilsaw.

I while back a friend of mine who used to mill big redwoods in Big Sur told me to turn my handle around. I like it that way. I just grab the handle and lean on my elbow with my hip- if you can picture that.

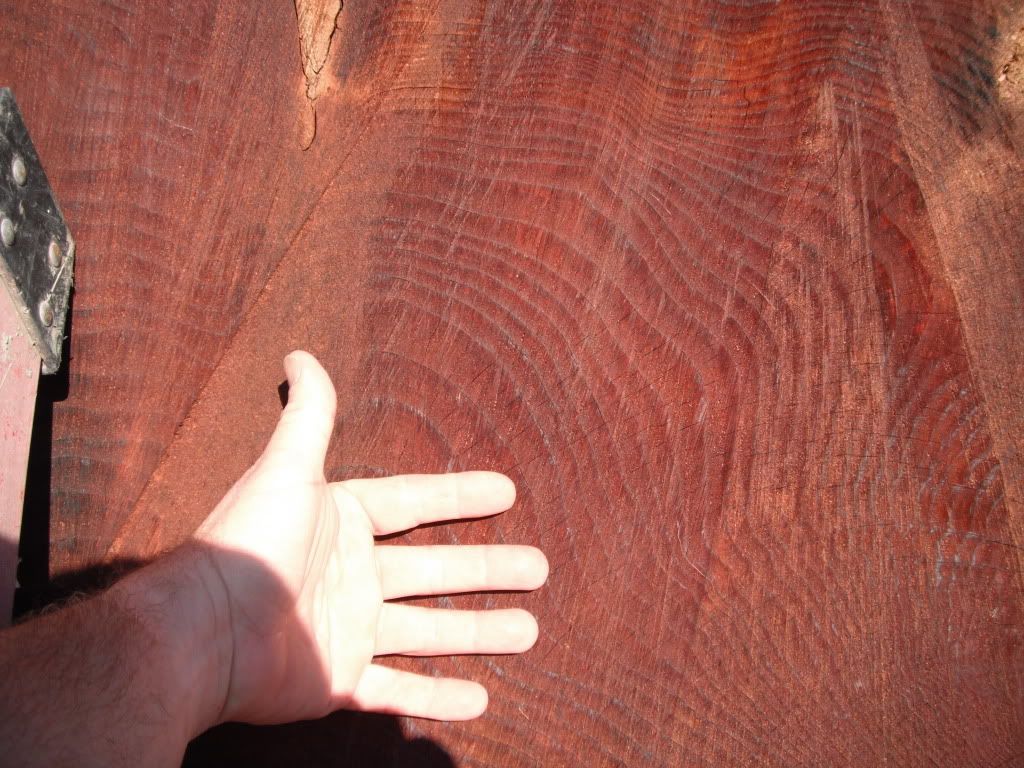

Here's a pic of the kind of cedar I'm working with and another how it looks with a clear satin finish.

View attachment 436957 View attachment 436958

![20150720_085402[1].jpg 20150720_085402[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120681-d36f26f6087f3e9f70d876bf6af7c3f1.jpg)

![20150720_101400[1].jpg 20150720_101400[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120683-7a7f93f96411145424539c6dc6afe40d.jpg)

![20150720_113138[1].jpg 20150720_113138[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120684-bddbfbb1c98a93571fb83711c8fc1c33.jpg)

![20150720_115341[1].jpg 20150720_115341[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120685-9c11b37c9ebc03e228365c086e7c8c88.jpg)

![20150720_101416[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120682-01abb6fa72c0db698e9f9463eeb62a77.jpg)

![20150720_121353[1].jpg 20150720_121353[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120688-97df03295640fec2f88cdffd5cc4876b.jpg)

![20150720_123916[1].jpg 20150720_123916[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120692-4faed78abf65d0d0a715687507ed3dfb.jpg)

![20150720_123922[1].jpg 20150720_123922[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120693-23c2dac4eb6f54018b52bd6f27d8517d.jpg)

![20150720_125825[1].jpg 20150720_125825[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120694-7d236eeb1fb3bd09f79ef2dca14885bd.jpg)

![20150720_123813[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120689-d50b10ba79572ed6b705808b762d6735.jpg)

![20150720_130242[1].jpg](https://cdn.imagearchive.com/arboristsite/data/attachments/120/120697-31a3613c7f8b01ad1023a42335fb7a37.jpg)