Peter White

PAW

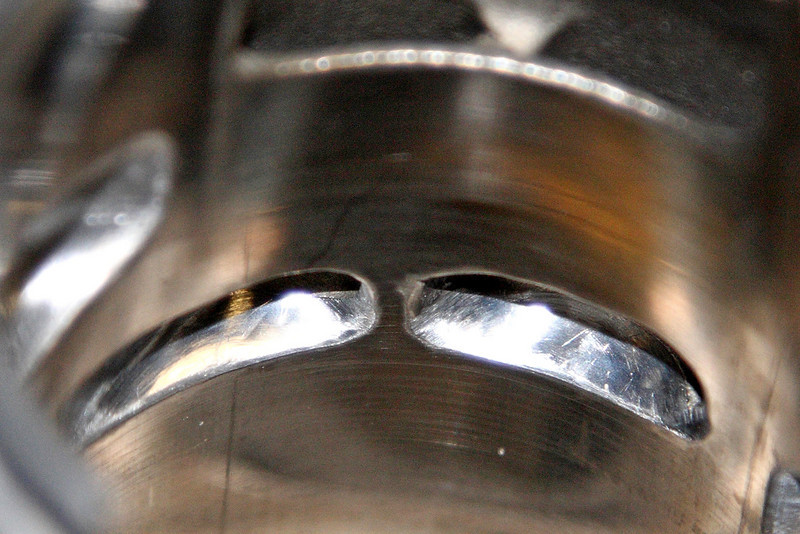

So, I've got everything together, and I'm tearing into my Husky 55. I got the cylinder off today and everything looks brand new. Not many hours on the saw. I measured squish beforehand at .044", and the base gasket is .010". I plan to delete the base gasket and reassemble with something like Yamabond (OK, I don't have EVERYTHING together...). If I have this correct, the following will happen when I drop the cylinder .010"

1) The rising piston skirt will open the intake sooner. Can't fix that...

2) The falling piston skirt will close the intake later. I can raise the roof of the intake .010" to compensate.

3) The falling piston dome will open the exhaust port later. I can raise the roof of the exhaust .010" to compensate.

4) The falling piston dome will close the exhaust later. Can't fix that, either.

So, if that is correct, I will plan on widening the ports to 65% of piston skirt width, or to material limits, whichever comes first. I will raise the tops of the ports .010" to compensate for base gasket delete. I will make the sides of the ports relatively straight. I am confused by some of the nomenclature relative to "roofs" and "floors" of the intake and exhaust port. I want to think that the roof is nearest the top of the cylinder and the floor is near the bottom. But looking at pictures and comments on other posts (Brad's "Porting the 361 Big Bore", for example), I get the impression that the roof is where the port opens and the floor is where it closes. I notice from pictures that it is typically the bottom of the intake that gets the larger arc shape and the top that is flat. And for the exhaust, it appears the top is radiused and bottom is flat (Brad says, "Make the roof of the exhaust and floor of the intake "flattish",but make sure there's a slight radius so that the ring is tucked back in gently and doesn't snag.... The port should close from the sides to the center. The floor of the exhaust and roof of the intake are not that critical since that's not where flow initiates"). So, the intake port closes as the piston skirt falls past it on the down stroke, so the bottom gets the larger radius. And the exhaust port closes as the piston dome rises past it on the up stroke, so the top gets the larger radius. Is that right? But the opposing sides need a slight, but smaller radius, also - but flatter? The slight radius to be sure the rings are tucked back in nicely?

Thanks, I appreciate the help in advance - I will post pics next.

1) The rising piston skirt will open the intake sooner. Can't fix that...

2) The falling piston skirt will close the intake later. I can raise the roof of the intake .010" to compensate.

3) The falling piston dome will open the exhaust port later. I can raise the roof of the exhaust .010" to compensate.

4) The falling piston dome will close the exhaust later. Can't fix that, either.

So, if that is correct, I will plan on widening the ports to 65% of piston skirt width, or to material limits, whichever comes first. I will raise the tops of the ports .010" to compensate for base gasket delete. I will make the sides of the ports relatively straight. I am confused by some of the nomenclature relative to "roofs" and "floors" of the intake and exhaust port. I want to think that the roof is nearest the top of the cylinder and the floor is near the bottom. But looking at pictures and comments on other posts (Brad's "Porting the 361 Big Bore", for example), I get the impression that the roof is where the port opens and the floor is where it closes. I notice from pictures that it is typically the bottom of the intake that gets the larger arc shape and the top that is flat. And for the exhaust, it appears the top is radiused and bottom is flat (Brad says, "Make the roof of the exhaust and floor of the intake "flattish",but make sure there's a slight radius so that the ring is tucked back in gently and doesn't snag.... The port should close from the sides to the center. The floor of the exhaust and roof of the intake are not that critical since that's not where flow initiates"). So, the intake port closes as the piston skirt falls past it on the down stroke, so the bottom gets the larger radius. And the exhaust port closes as the piston dome rises past it on the up stroke, so the top gets the larger radius. Is that right? But the opposing sides need a slight, but smaller radius, also - but flatter? The slight radius to be sure the rings are tucked back in nicely?

Thanks, I appreciate the help in advance - I will post pics next.