Not a Guru, but my $.02

With the popup and the jug drop, you're not changing the (already excellent) exhaust or transfer timing very much, if any.

Tightening squish alone will drop jug slightly onto piston, so there will be a slight difference in blowdown. If the exhaust drops 1*, the transfers will drop slightly more because of rod angle.

You're gonna get slightly more intake. Brad likes that.

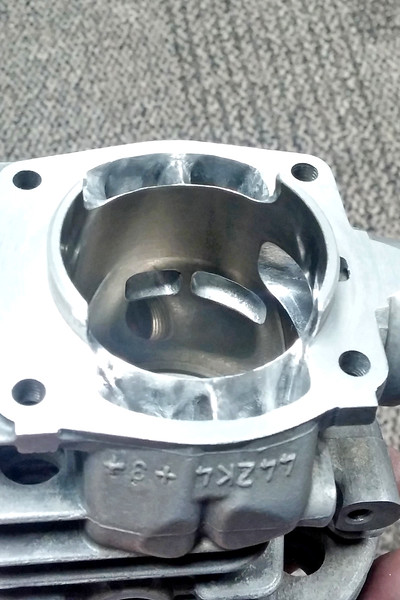

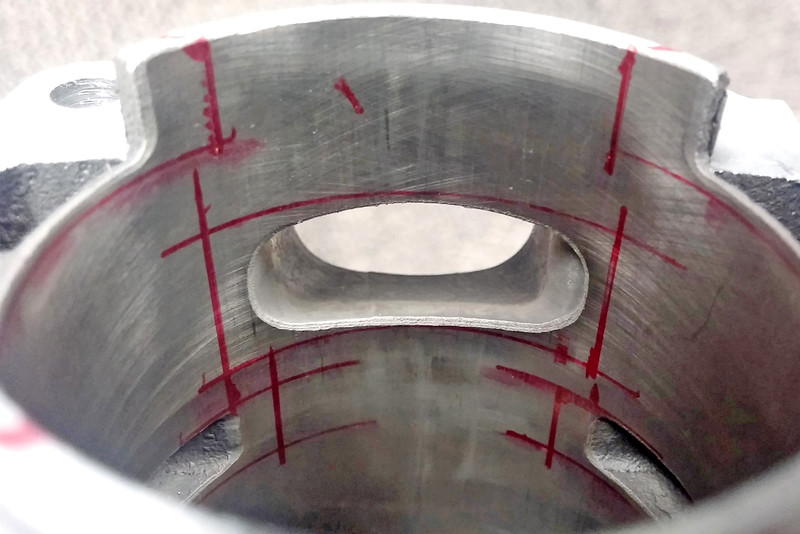

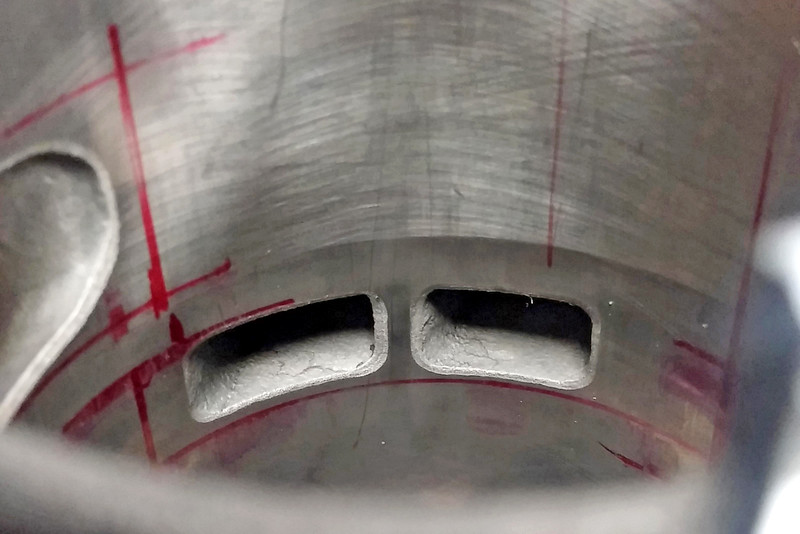

No guru here, but I'd Widen the intake and exhaust and not change the timing at all. Square up the intake.

If the design is a 1 ring hoosky with a central ring pin above the intake port at BDC, then you can widen the intake to 1-2mm from the skirt edge. You won't have to worry about the ring gaps like you do on the Stihl 026.

I know on those, the lower inlet transfers need work.

Message Mattyo. He built a 350 with a 346 45mm top that was purely amazing. Plus, the guy that's doing your machine work builds an incredible 346, as you know.

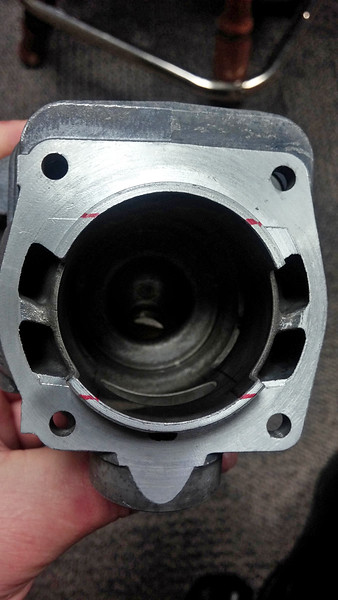

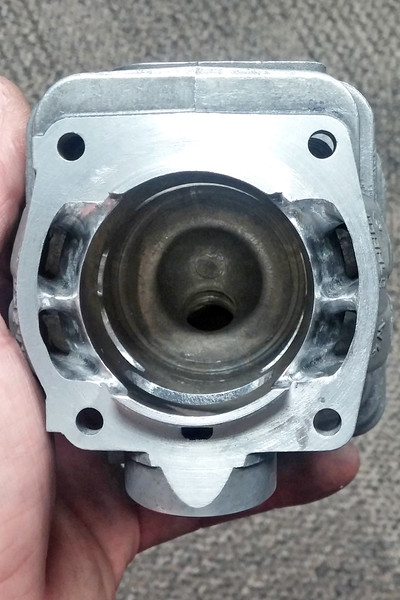

Below is a pic of "squaring up the intake". In case you don't know what I mean. It's an unfinished 026 intake port.