Daninvan

ArboristSite Operative

After getting the 48" doubleheaded mill all set up the other day with a 2100 on each end (on the floor), I was looking forward to pushing it through some wood today for the first time.

So we headed to the beach log dump area this morning under threatening skies. No rain, yet.

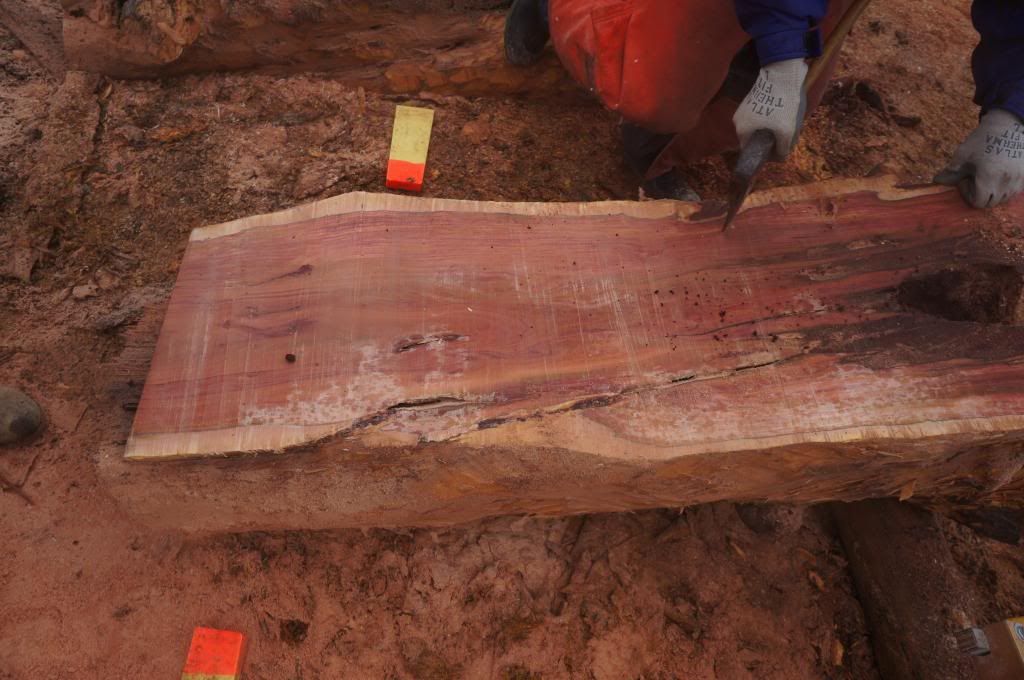

I had a plum log (foregorund), a larger Monterey cypress (left), and a mystery log (right) set up. We cut the end off the plum, it was rotten in the middle as you can see on that one end, but showed good colour so we decided to mill it up.

Next we cut the crotch end off the Monterey cypress, unfortunately my 385 died in the middle of the cut for no apparent reason, I had to get my buddy to finish the cut off with his small saw. And then we saw that the log was badly rotten, it looked like it had started rotting from the crotch down, so we abandoned it as none of us really wanted that wood. Which was too bad since that was the main log I wanted to mill today, and was the one I wanted to use the double mill on.

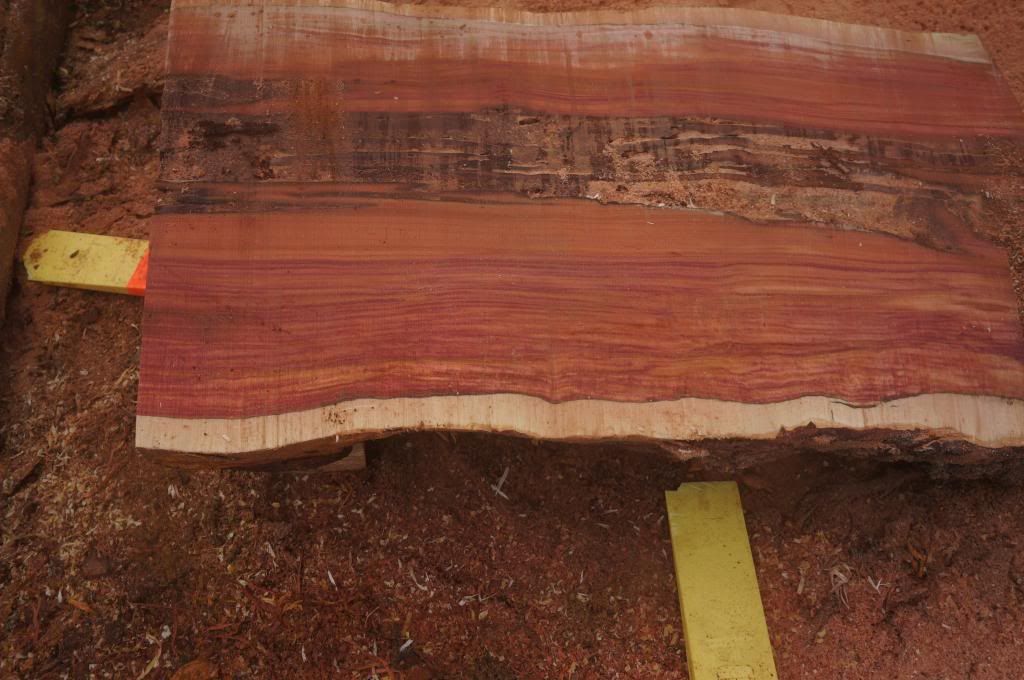

So instead we started milling up the mystery log, using the double mill. The log quickly revealed itself to be a nice maple, but the double mill gave us some fits and we decided not to use it any more. We found that the bar was sagging, resulting in a curved cut, and the mill wound up getting twisted and jammed in the cut. With the two powerheads on there the sound was sure impressive, and there was no shortage of power. You will have to take my word for it as we foolishly didn’t do any pictures or videos of it in operation. We probably should have done the first couple of cuts with the regular mill as the log was obviously narrower at the top, then switch to the double just for a few cuts in the middle where the log was widest.

By then the weather was starting to turn, the rain moved in.

So we headed to the beach log dump area this morning under threatening skies. No rain, yet.

I had a plum log (foregorund), a larger Monterey cypress (left), and a mystery log (right) set up. We cut the end off the plum, it was rotten in the middle as you can see on that one end, but showed good colour so we decided to mill it up.

Next we cut the crotch end off the Monterey cypress, unfortunately my 385 died in the middle of the cut for no apparent reason, I had to get my buddy to finish the cut off with his small saw. And then we saw that the log was badly rotten, it looked like it had started rotting from the crotch down, so we abandoned it as none of us really wanted that wood. Which was too bad since that was the main log I wanted to mill today, and was the one I wanted to use the double mill on.

So instead we started milling up the mystery log, using the double mill. The log quickly revealed itself to be a nice maple, but the double mill gave us some fits and we decided not to use it any more. We found that the bar was sagging, resulting in a curved cut, and the mill wound up getting twisted and jammed in the cut. With the two powerheads on there the sound was sure impressive, and there was no shortage of power. You will have to take my word for it as we foolishly didn’t do any pictures or videos of it in operation. We probably should have done the first couple of cuts with the regular mill as the log was obviously narrower at the top, then switch to the double just for a few cuts in the middle where the log was widest.

By then the weather was starting to turn, the rain moved in.