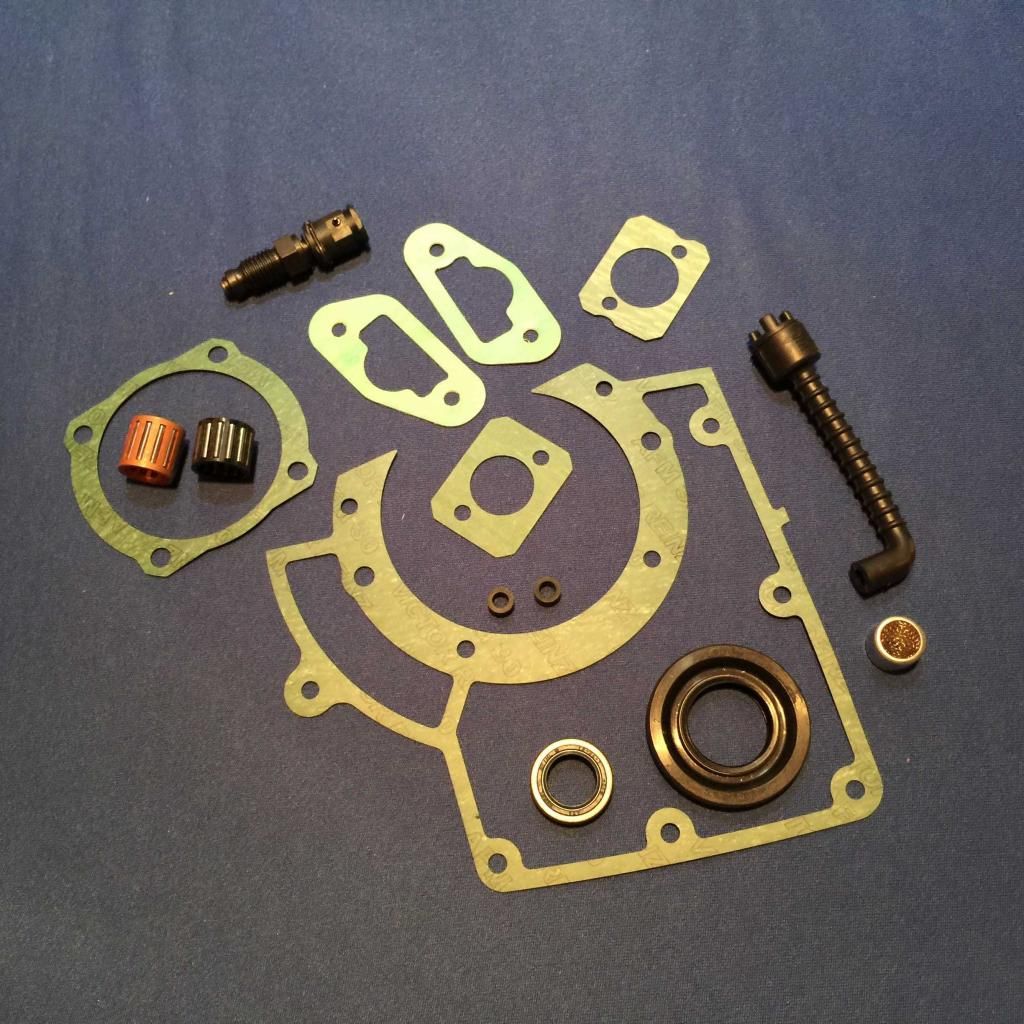

Too cold out to even look at the garage this week, I got some OEM seals and parts in so it felt like I made progress even though I basically did nothing.

I guess I don't care which starter setup I use as long as I don't have the goofy orange rectangle style badge and removable screen cover on the recoil, that may seem childish, but truth be told I don't need the saw at all and am building it completely for fun so if I make a compromise for the sake of simplicity, every time I look up at it on the wall, I will hate the saw. Once is starts and revs up and gets tuned it will get drained and become a wall hanger. I am not sure I have any of the guts for the Pawl style now, the one assembled narrow case with the recoil installed may actually be the pieces that fit inside the friction cup. If the friction style works, I may just get the rebuild kit Poge mentioned.

Never worked on a saw with points, I am hoping I have or can get a regular "coil" like used on modern saws for this project. I got the chain brake clutch cover disassembled and ready for powdercoating, but I am sure I have a good 2-4 hours of crankcase disassembly left before parts can ship off.

DDave