AndyR

ArboristSite Operative

I couldn't stand it any longer. I took a day off and milled the upper log from the cherry tree I posted about removing a while back. It was knotty and had some bark and indications of beetles inside, but I think I'll get some good pieces out of it. Since it had so many knots, I cut two slices at about three inches thick. I figured I can cut out betwen the knots and use the thick parts for table legs-or resaw later if needed. I've heard that the best thing to do for the beetle larvae in the wood is to kiln dry it. Is there some other way that all of you air-dryers deal with this? Should I have just cut those sections out of the boards?

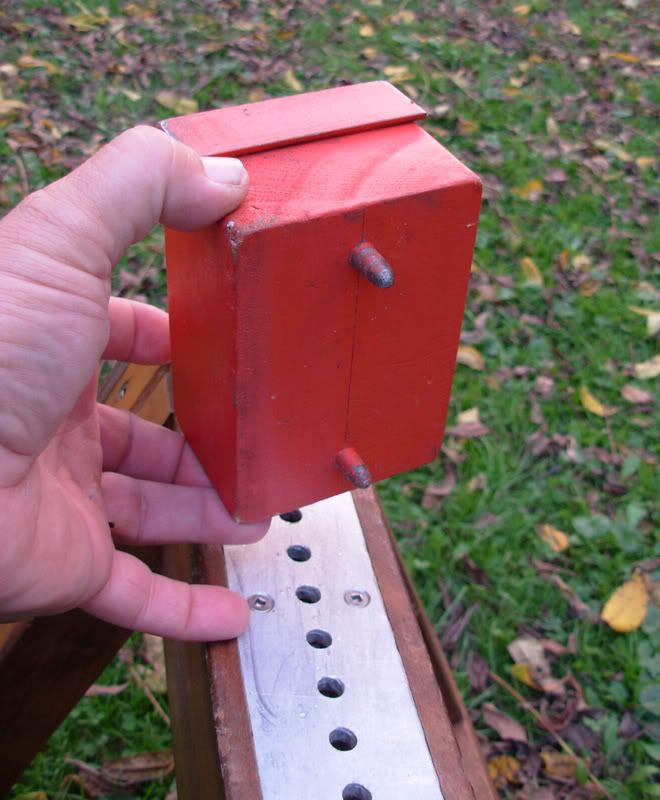

I kinda did this Woodshop style. Squaring the log with the CSM and then slicing boards with the Ripsaw. All members of the team (Ripsaw w/036, CSM w/395xp, and the Echo cs440) worked well together. It seems that the extra drag of the blade etc. causes the saw to not want to idle too well, though it got better as it warmed up. I also noticed that I needed to keep the rpms up in the cut or if it got to slow it would stall. Which was a pain because I had to wedge the cut and back the Ripsaw out to get it started again.

Overall, the boards aren't perfect, but aren't too bad either for the first three cuts.

I kinda did this Woodshop style. Squaring the log with the CSM and then slicing boards with the Ripsaw. All members of the team (Ripsaw w/036, CSM w/395xp, and the Echo cs440) worked well together. It seems that the extra drag of the blade etc. causes the saw to not want to idle too well, though it got better as it warmed up. I also noticed that I needed to keep the rpms up in the cut or if it got to slow it would stall. Which was a pain because I had to wedge the cut and back the Ripsaw out to get it started again.

Overall, the boards aren't perfect, but aren't too bad either for the first three cuts.