Joeypole

ArboristSite Member

I bought a box of parts which now resembles a 338XPT.

Question #1:

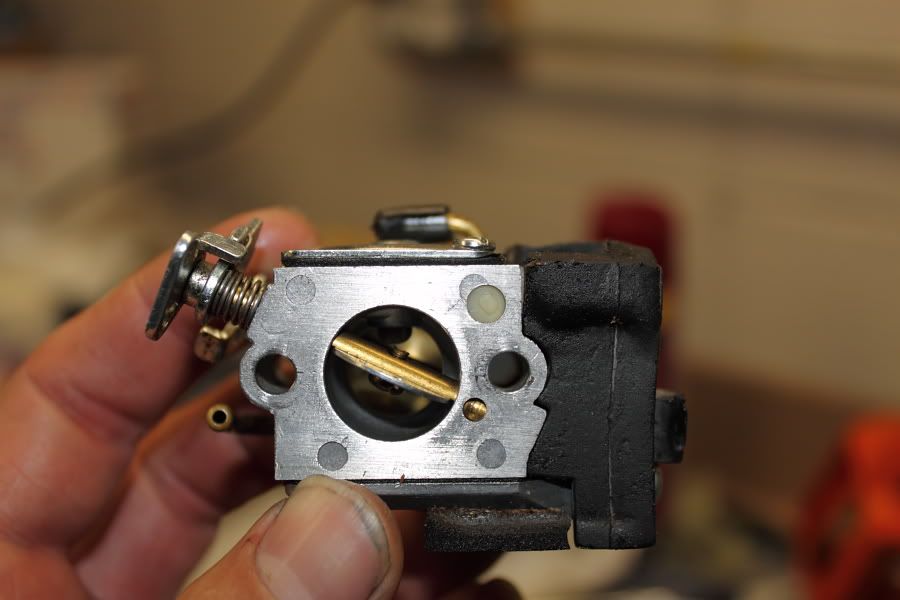

The air purge up in the handle is broke (atleast it looks that way) and I got a new one. But there are no lines to it and the top of the carb has a factory looking rubber plug over it and the nipples where the lines would go on the purge are snipped real close. There is no bubble on it. Where there some early ones that didn't have the air purge bubble. It starts right up so I'm not worried about it, just wanted clarification.

The unit is a 2003 I believe by the serial number.

Question #2:

With the saw off, should the clutch drum/sprocket spin freely? Mine binds a little bit and doesn't spin freely. With the bar and chain on I can feel a little binding as well. I pulled the bearing to look at it and it looks fine with no metal or wood in it and its all there. I cleaned it again and put it back on and it still binds.

So should it spin freely or be a little tough to spin?

Thanks,

Joe

Question #1:

The air purge up in the handle is broke (atleast it looks that way) and I got a new one. But there are no lines to it and the top of the carb has a factory looking rubber plug over it and the nipples where the lines would go on the purge are snipped real close. There is no bubble on it. Where there some early ones that didn't have the air purge bubble. It starts right up so I'm not worried about it, just wanted clarification.

The unit is a 2003 I believe by the serial number.

Question #2:

With the saw off, should the clutch drum/sprocket spin freely? Mine binds a little bit and doesn't spin freely. With the bar and chain on I can feel a little binding as well. I pulled the bearing to look at it and it looks fine with no metal or wood in it and its all there. I cleaned it again and put it back on and it still binds.

So should it spin freely or be a little tough to spin?

Thanks,

Joe