sILlogger:

If you had those trees to do over again.

What would you have done different?

Would binders above and below have worked?

******************

to be honest..i prolly wouldn't do anythign different...about the only other thing would be to cut the hinges a little thinner...but then you run the chance of the tree setting down on your saw...

How strong a lean did they have?

Any wind, wedging forces etc come into play?

*****************

the bigger white oak had a pretty far lean to it..but nothing extradinary..the chinkapin didn't have a great deal of lean on it either...they were just fluke things that happened..ive cut worse trees before and since the same way...you can do it 100 times....and the 101st might get you..

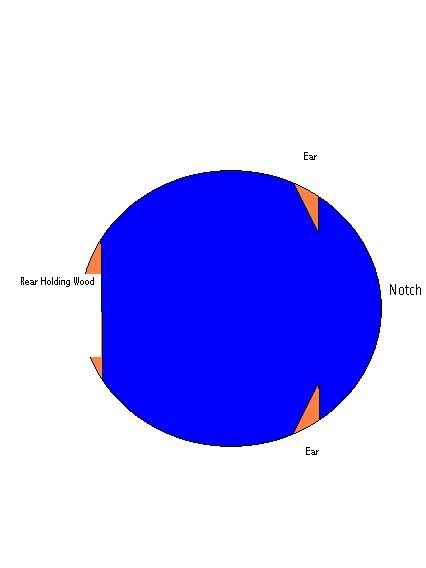

ive got pretty good sized hardwoods with hard leans on them....notched them(shallow) bored the face(shallow) bored one side(left my "ear" of holding wood on the corner of the notch) and gone pretty well all the way to the back of the tree...and went around the to other side and bored in and left and "ear" and got 1/4 the way around that side and it would pull the entire back part of the stump out out of the ground....root and all....

...i think the last one that i cut that did that was a sycamore on the edge of a creek..it was right at 50" on the stump..and was prolly leaning at a 50-60 degree angle... shallow undercut..bore off one side..just got started in the other and it pulled the last 2' of the back that i still had to cut up out of the ground.......never hurt the log...a facecut/backcut and the tree would have exploded

By "turning it loose" do you mean you had completed the bore toward the rear and then finished with cutting the remaining strap at the rear from the outside?

*******************

yea..when i say turn it loose i mean i either cut all the way out the back after boring it...or i left some wood, pulled the saw out nipped the wood with the saw to let the tree to over. if you don't leave enough...or the tree is leaning really hard it can split out the back of the tree..or pull the root out of the ground(fairly common)

The ears, about 6 inches down and in 4 inches?

*******************

that 6x4" the size of the "holding ears"...6" towards the center of the tree from the end of the notch and 4" deep into the tree....those are good sized "ears"...i typically don't cut them that big...alot of times i'll cut 30" trees and i'll cut my "ears" and they will only be a 1"x1" piece of holding wood...(on hickory i cut them as small as possible to keep from pulling the side of the tree out) if the tree species is known to split or if it is a high grade tree in which i don't want any fiber pull..i will nip the ears off after i turn the tree loose and let it free from the stump=no fibre pull

you can also use the ears...or the cutting of them to turn or roll a tree as it falls...if you need a tree to go in a gap...but the tree is wantin to hit another one...you can cut the ear off opposite of the side of the area where you want it to land...and when it hits the other tree it will roll.......right where u want it if you do it right... you can also use this method to land the tree with a fork in a way that it won't split....(if the trees land with one fork above the other they will often split the tree...sometimes all the way up the butt and blow the tree clean in half.

Did the Chinkapin also split at the back of the hinge?

(Not trying to be a pest, just trying to understand.)

It sure sounds like you did everything right.

as for the chinkapin...i make the undercut...bored it while i was doing it..cut the notch...made my ears on both sides...

(all while on one side of the tree)...dogged in and motored out the back of the tree....the tree split out the rear...about the last 3/4"(yes...i only had 3/4" of holding wood left when it split and started to go....and then split out the middle...my ears on this tree were prolly 1.5"x3"......it was another one of those fluke things