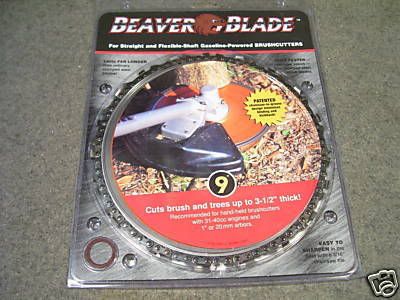

I have searched and even called DR technical support to find out the thickness of the double blade with chainsaw "Beaver Blade" -

at the shaft/arbor- not the kerf/cut thickness

the reason being that some of the brushcutter shafts are barely long enough to handle even a single blade.

About to order a beaver blade to help with clearing four acres for an orchard planting . . .

Am I going to have to change or mod the left hand threaded flange nut or the washer to fit this on the brushcutter shaft ?

Anyone that has a beaver blade able to give me an idea of the thickness at the shaft/arbor ? . . . 1/8" ? or more ?

Thanks in advance.

at the shaft/arbor- not the kerf/cut thickness

the reason being that some of the brushcutter shafts are barely long enough to handle even a single blade.

About to order a beaver blade to help with clearing four acres for an orchard planting . . .

Am I going to have to change or mod the left hand threaded flange nut or the washer to fit this on the brushcutter shaft ?

Anyone that has a beaver blade able to give me an idea of the thickness at the shaft/arbor ? . . . 1/8" ? or more ?

Thanks in advance.