I tried every mounting position possible (the instructions are not terribly clear, besides, who reads instructions ?

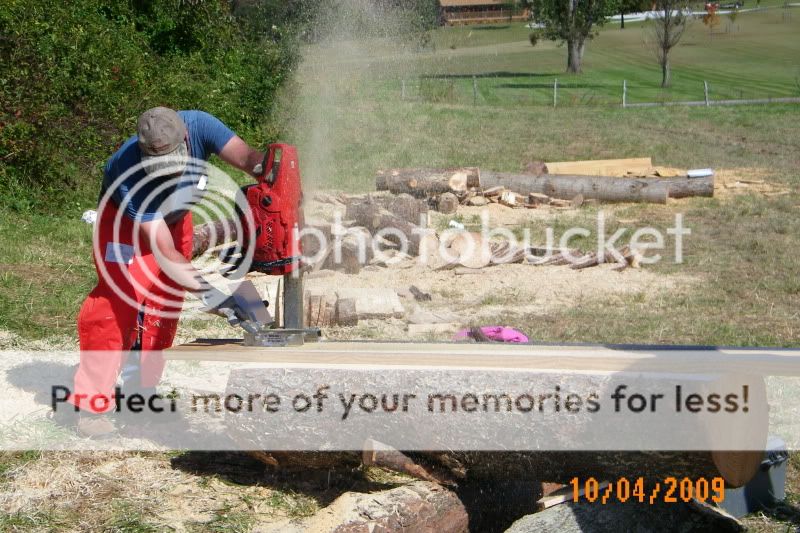

) and it worked best as shown in the picture, with the chain brake facing the pexiglass shield.

The saw is cutting on the bottom of the bar like it is supposed to, and the cut pulls the saw against the guide board. Sawdust is ejected on the side opposite of the operator (as long as there is no wind to blow the dust back in your face

).

It is tempting to mount it so that the saw cuts with the top of the bar, ejecting sawdust toward the ground instead of up in the air. However, cutting forces push the saw away from the guide board and you have to push back extra hard to maintain control. It can be done, but it's tiring and the cut is not as straight.

).

).