You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

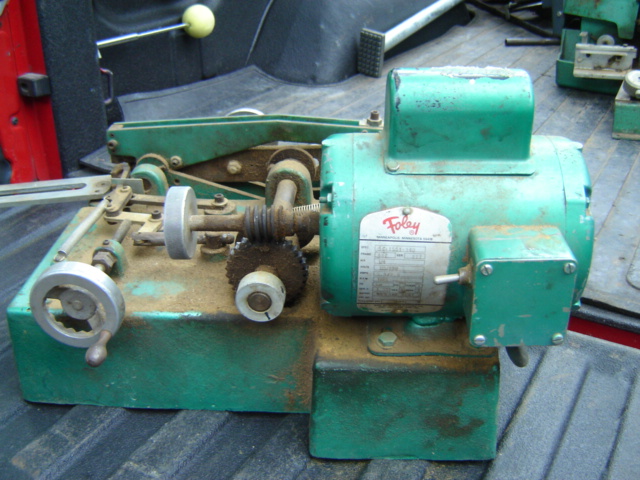

Foley Saw Sharpener ... has anyone used one of these?

- Thread starter 046

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

my dad has a foley belsaw charpener, but it looks nothing like that at all. how does it work?

don't know... that's why I'm asking...

my dad has a foley belsaw charpener, but it looks nothing like that at all. how does it work?

tanker

ArboristSite Operative

That looks like a sharpener for circular saw blades . Scott

belsaw and foley joined---kansas city, mo. they would have the manuals for it--or could reprint them--good machinery--meant to last---

BlueRider

ArboristSite Guru

- Joined

- Feb 7, 2007

- Messages

- 550

- Reaction score

- 125

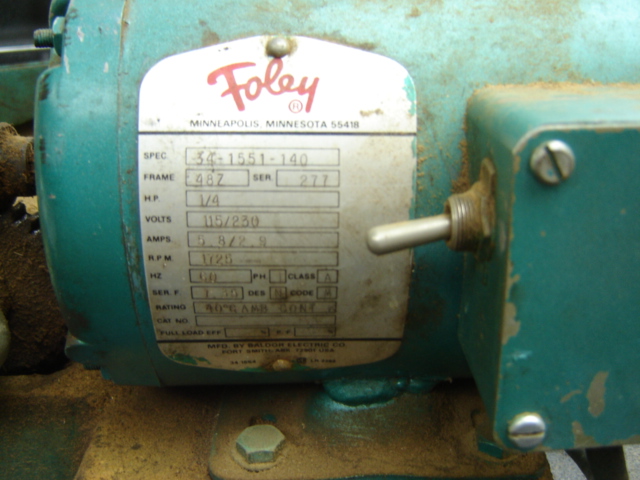

I don't believe the foley bellsaw company that mede your sharpener is the same foley bellsaw that is located in Kansas City. The bell and saw logo shown in one of the pictures is the same log used by Bellsaw company located in San jose Ca and the current maker of bellsaw planers. Of course the company may have been devided up and we are both correct.

Here is a link for a guy with a blog and a bunch of manuals for saw sharpeners, including foley. http://sawfiler.blogspot.com

Here is a link for a guy with a blog and a bunch of manuals for saw sharpeners, including foley. http://sawfiler.blogspot.com

vinsapprentice

New Member

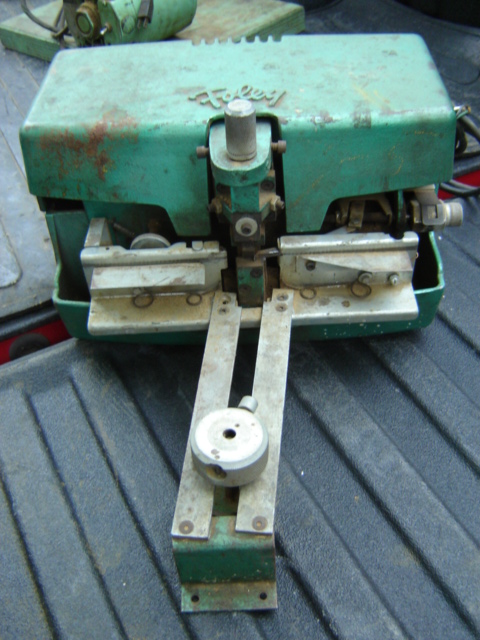

OK 046 this is what I know. The retoother is part of the whole set up for sharpening carpenters hand saws. After a number of sharpenings the saw teeth lose their shape and vary in height. If the teeth are not all the same height you can joint the saw with a file and recut the teeth with a taper file or you can use the Foley retoother which uses the cutting dies to cut new teeth in the edge of the saw blade. In order to make this machine run properly you need retoothing bars - nothing more than a steel bar with evenly spaced notches - that allow the retoother to advance the blade as each tooth is cut. Bars were available for tooth spacing of 4 tpi (ripsaws) to about 15 tpi (finer cut crosscut saws).

Next step would be to mount the saw blade in the setter to have the correct set put into the teeth.

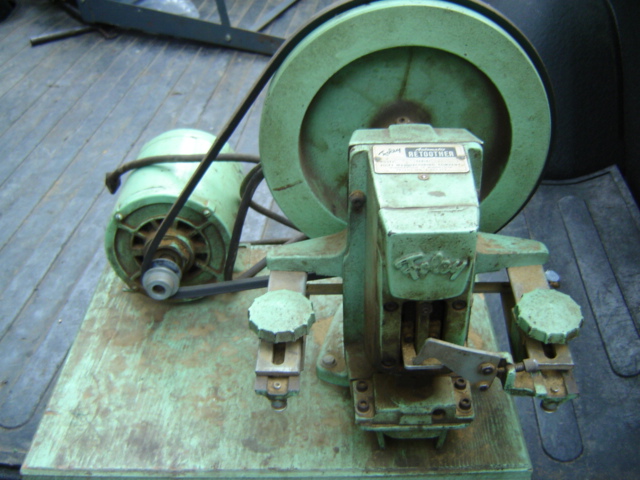

Final step is to put the saw into a filer. This machine holds a taper file and runs it through each tooth on the blade and can be adjusted for each type of saw and tpi. The saw is clamped to a carrier bar which runs through the filer and keeps the saw in the proper position for the file to run through.

You don't show a picture of the filer. I have three filers and no retoother or setter. You never seem to find all of the stuff you need for these machines in one place. The hardest parts to find are the retoothing bars - without these the machine won't work. If you have these all you need to do is find a filer and you have a complete set up for doing hand and circular saws. Foley also made some wheel attachments which could be used for sharpening band saw blades on the filers.

Keep poking around the internet. I can't remember where but someone posted a video or the manual for setting up the retoother.

Sorry for the stuff I left out but this was meant to be an overview. Hope this helps some. We're all sort of refiguring out how these things worked since there are really no sharpening shops left.

Next step would be to mount the saw blade in the setter to have the correct set put into the teeth.

Final step is to put the saw into a filer. This machine holds a taper file and runs it through each tooth on the blade and can be adjusted for each type of saw and tpi. The saw is clamped to a carrier bar which runs through the filer and keeps the saw in the proper position for the file to run through.

You don't show a picture of the filer. I have three filers and no retoother or setter. You never seem to find all of the stuff you need for these machines in one place. The hardest parts to find are the retoothing bars - without these the machine won't work. If you have these all you need to do is find a filer and you have a complete set up for doing hand and circular saws. Foley also made some wheel attachments which could be used for sharpening band saw blades on the filers.

Keep poking around the internet. I can't remember where but someone posted a video or the manual for setting up the retoother.

Sorry for the stuff I left out but this was meant to be an overview. Hope this helps some. We're all sort of refiguring out how these things worked since there are really no sharpening shops left.

thanks .. it's starting to make sense.

what I need to do is find someone that needs all my equipment.

would be happy to make someone a deal for all of it.

shipping would be a bear. some of this equipment is heavy.

best to have someone pick it up.

what I need to do is find someone that needs all my equipment.

would be happy to make someone a deal for all of it.

shipping would be a bear. some of this equipment is heavy.

best to have someone pick it up.

OK 046 this is what I know. The retoother is part of the whole set up for sharpening carpenters hand saws. After a number of sharpenings the saw teeth lose their shape and vary in height. If the teeth are not all the same height you can joint the saw with a file and recut the teeth with a taper file or you can use the Foley retoother which uses the cutting dies to cut new teeth in the edge of the saw blade. In order to make this machine run properly you need retoothing bars - nothing more than a steel bar with evenly spaced notches - that allow the retoother to advance the blade as each tooth is cut. Bars were available for tooth spacing of 4 tpi (ripsaws) to about 15 tpi (finer cut crosscut saws).

Next step would be to mount the saw blade in the setter to have the correct set put into the teeth.

Final step is to put the saw into a filer. This machine holds a taper file and runs it through each tooth on the blade and can be adjusted for each type of saw and tpi. The saw is clamped to a carrier bar which runs through the filer and keeps the saw in the proper position for the file to run through.

You don't show a picture of the filer. I have three filers and no retoother or setter. You never seem to find all of the stuff you need for these machines in one place. The hardest parts to find are the retoothing bars - without these the machine won't work. If you have these all you need to do is find a filer and you have a complete set up for doing hand and circular saws. Foley also made some wheel attachments which could be used for sharpening band saw blades on the filers.

Keep poking around the internet. I can't remember where but someone posted a video or the manual for setting up the retoother.

Sorry for the stuff I left out but this was meant to be an overview. Hope this helps some. We're all sort of refiguring out how these things worked since there are really no sharpening shops left.

I own a saw sharpening/machine shop, hardly see many hand saws anymore. Was a time when I was doing about 10 a week or more. The advent of the hardened teeth (can't be filed have to grind and you can not reset them as they are so hard they will snap off) and really inexpensive handsaws has reduced this aspect of the trade to almost nothing. I also use to resharpen and set narrow width bandsaw blades, had machines for that also same senario as hand saws.

Still get a few plain steel circle saw blades now and again but by and large they have been replaced by carbide tipped units which I also service. My response to the industry changes has been to become a small full service machine shop. I do the one ups, repairs, remanufacture, short runs and that the fancy shops do not want to become involved with. ( not cost effective for them)

Still get a few plain steel circle saw blades now and again but by and large they have been replaced by carbide tipped units which I also service. My response to the industry changes has been to become a small full service machine shop. I do the one ups, repairs, remanufacture, short runs and that the fancy shops do not want to become involved with. ( not cost effective for them)

tomtrees58

Addicted to ArboristSite

i have one a [kb 1-a ] four chain saws that looks like four ice skates go to bell saw web site tom trees

Similar threads

- Replies

- 0

- Views

- 203

- Replies

- 0

- Views

- 380