Craigslist. I had to call the guy. I will be picking it up in the morning.

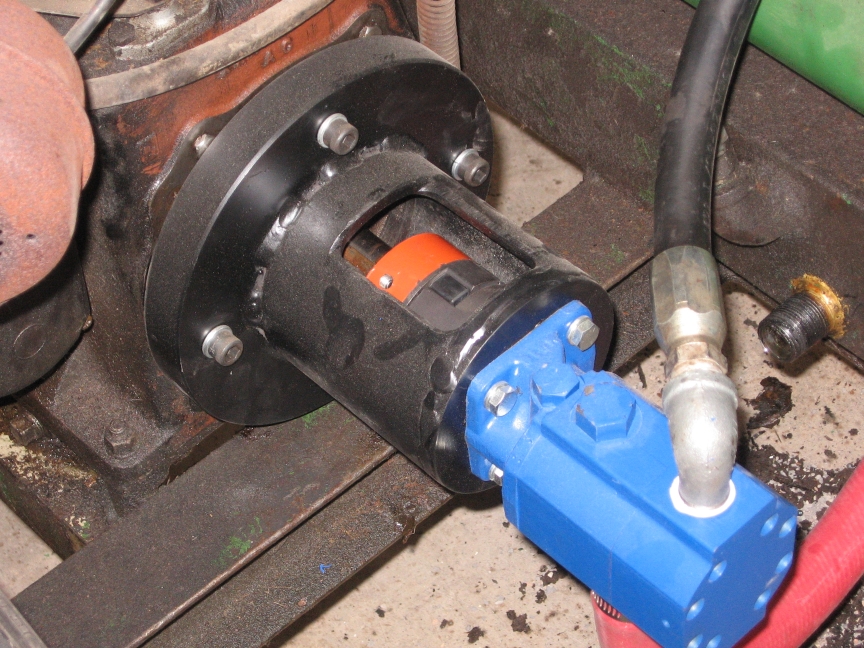

This one has a few interesting features. The Wisconsin engine is a keeper. It looks like they are driving the pump with a chain drive. That makes me think single stage pump (something mis-appropriated from the mine) The cylinder looks good but the rod size might be a touch small. Overall the construction looks good :hmm3grin2orange:

Then I will scratch my head until I turn it into another self propelled model!

This one has a few interesting features. The Wisconsin engine is a keeper. It looks like they are driving the pump with a chain drive. That makes me think single stage pump (something mis-appropriated from the mine) The cylinder looks good but the rod size might be a touch small. Overall the construction looks good :hmm3grin2orange:

Then I will scratch my head until I turn it into another self propelled model!

Gonna need a little larger engine...

Gonna need a little larger engine...