ChipMonger

ArboristSite Operative

There's only one way to handle something like this. I got his phone # and gave him a call. It's not fun facing the music, but it's the only way.

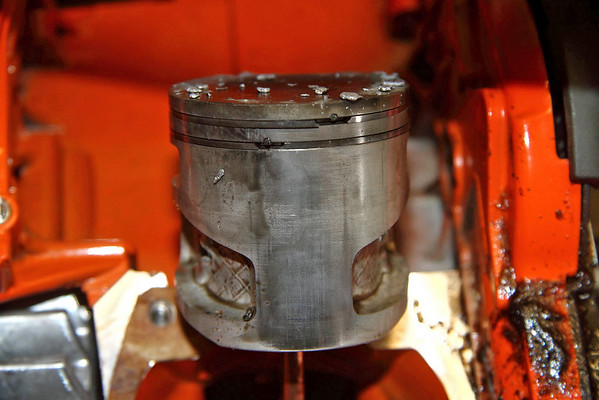

Well incase anyone is wondering, the saw is mine. I spoke to Brad over the phone, he was more than honest and felt horrible about it. Im a Firefighter and know the likely hood that "Sh*t happens". I worked on a Porsche race team and the first i built motor blew up. Turns out the crank failed from a crack that wasnt seen with magna fluxing...oh well it happened and we had to fix it. I dont blame brad for what happened he followed normal procedures for what he does. He built my 390 and 346, im more than happy with them. Hes doing everything he can to get my saw to me in perfect order. I cant ask for anything else. My hat is off to him.

Thanks Brad!