Brownpot Deaton

ArboristSite Operative

looks nice!

who do ou got helping you out there???

who do ou got helping you out there???

looks nice!

who do ou got helping you out there???

here is a barn we put up last year unfortunatly it is the neighbors

You can also install inverted king-post trusses between your spans... No need to go as large as the ones pictured in the link.

http://www.structuralsculpture.com/truss_king-post.htm

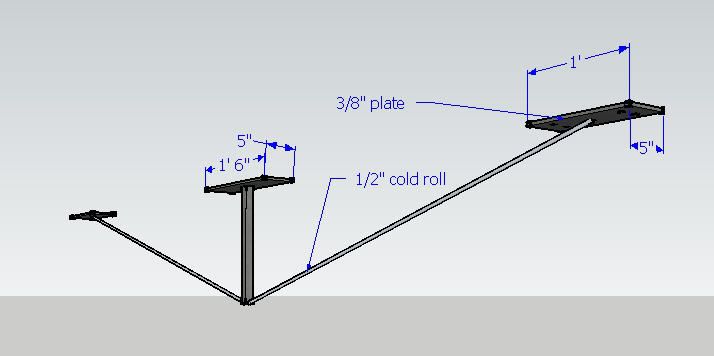

The inverted trusses can be fabricated out of wood or steel. You'd be really surprised what a 1/2" piece of cold rolled round, with a center post can do for span/load!

It would be fast to fab, and the material can be scavenged. Something like pictured below. They could also be made to easily post tension if need be... Cable and turnbuckles could also replace the 1/2" cold roll.

I thought about the knee braces but not the king post. I have miles of 1/2" threaded rod as well as cable. Thanks for the idea.

mm 16' span.. ouch. I'd put more posts in if it was mine.

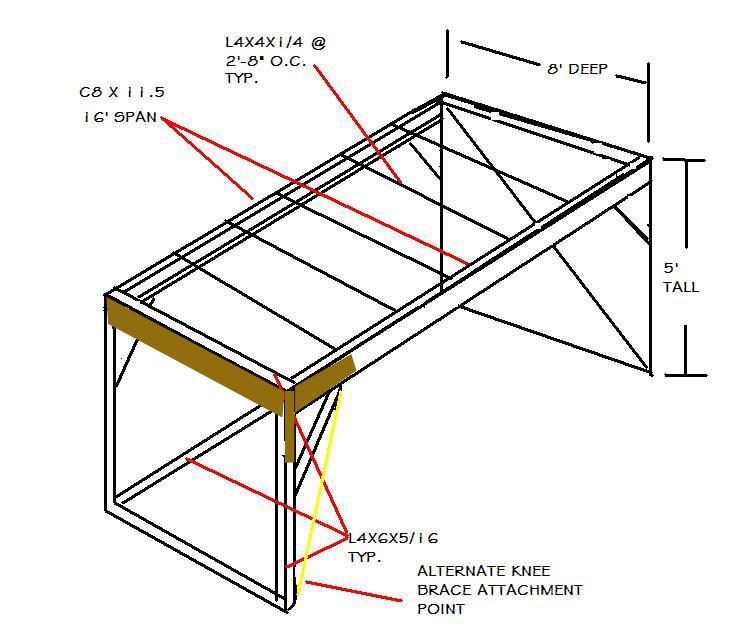

This is what I have in mind for the slab racks.

This is using what material I have already. Gotta love commercial construction.

C8x11.5 for the beams

L4x6x5/16 for the end frames- bottom will be L4x6x3/8 galvanized

L4x4x1/4 for the cross members (also have L3x5x1/4 if necessary)

Couple of questions for those of you that are smarter than me...

I want to keep the bottom clear as possible to get long lumber and slabs in and out but should the knee braces be in the alternate position shown in yellow?

Assuming a uniformly distributed load, about what would this be good for?

What about a point load mid-span on the C8?

If I increased the span the 20', what will those capacities be?

How can the frame be improved from an engineers perspective?

Is the moon made of cheese?

That is all... for now... I think...

Enter your email address to join: