Tried searching, but didnt find an answer yet. I bought a project 394 that will either become a ported 394 or a ported 395 big bore depending on the condition of the current jug (just got delivered today).

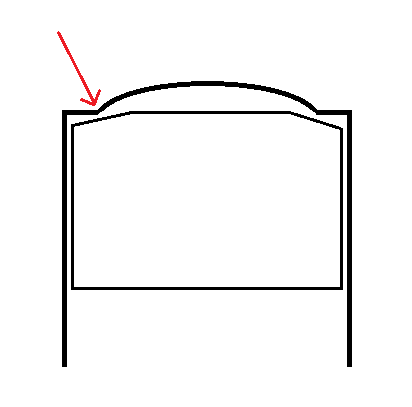

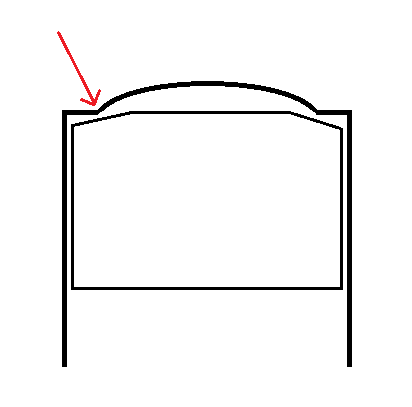

Anyway, after doing a popup piston, what is the proper way to measure squish? Would it still be the solder method, but measured at the pinch point indicated with the red arrow below?

Is there any standard amount of machining to do on the piston? I think I have all the timing numbers figured out, but not sure for the piston top. Planning a torquey work saw vs a race saw like some of the others around here.

Anyway, after doing a popup piston, what is the proper way to measure squish? Would it still be the solder method, but measured at the pinch point indicated with the red arrow below?

Is there any standard amount of machining to do on the piston? I think I have all the timing numbers figured out, but not sure for the piston top. Planning a torquey work saw vs a race saw like some of the others around here.