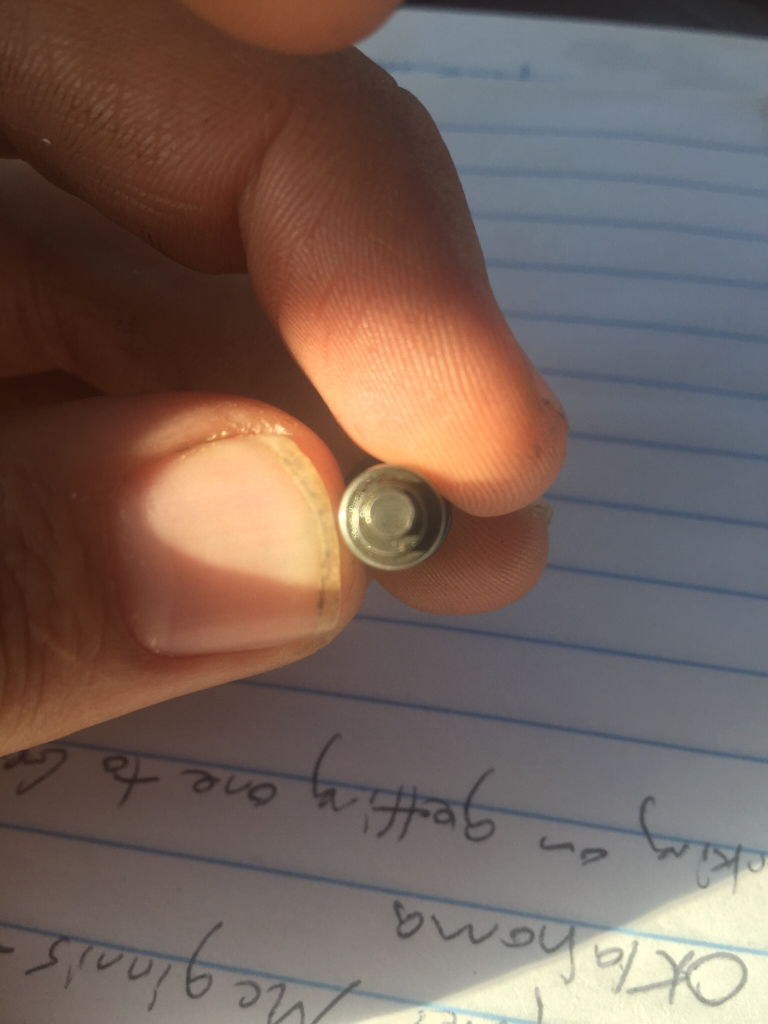

All went back together nicely. I found that pushing the new control bolt back in was easiest using a bench vise gently. Also, make sure that you have the cutout of the control bolt lined up so that it will clear the turn stop in the oil pump housing. Bushing also went back in very easily with bench vise.

Oil output was noticeably higher. I'm off to buy another control bolt for my 046 project now!

Oil output was noticeably higher. I'm off to buy another control bolt for my 046 project now!