Cody

ArboristSite Guru

- Joined

- Nov 25, 2013

- Messages

- 847

- Reaction score

- 1,790

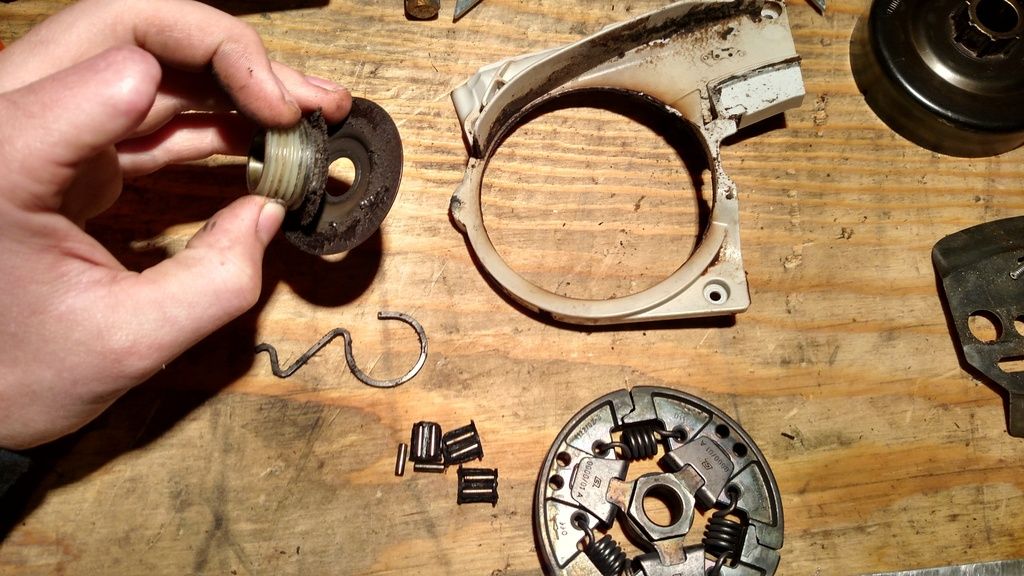

Doing routine maintenance on some saws and run into trouble with the 661. Clutch drum bearing is gone, came out in one piece but was brittle enough it broke into three pieces when squeezed. The plastic cover around the clutch is melted as well. Saw is less than a year old so I'm not sure what happened. I grease all the clutch drum bearings but I really only use my saws in the winter, don't like running them at temps above 60ºF. My first thought was maybe the clutch drum bearing was crap from the get go and wore out, causing the clutch to get hot and melt that cover, clutch seems just fine BTW. After taking that cover off though there is a piece of metal that is curved on the right side and on the left end of it has a little wiggle too it. I'm willing to bet that piece has to be attached to something but I don't have any diagrams to go off of. I would prefer not taking this to a dealer but it looks like I'll need to get that clutch out of the way, I do have a Stihl piston stop but still uneasy about removing the clutch.

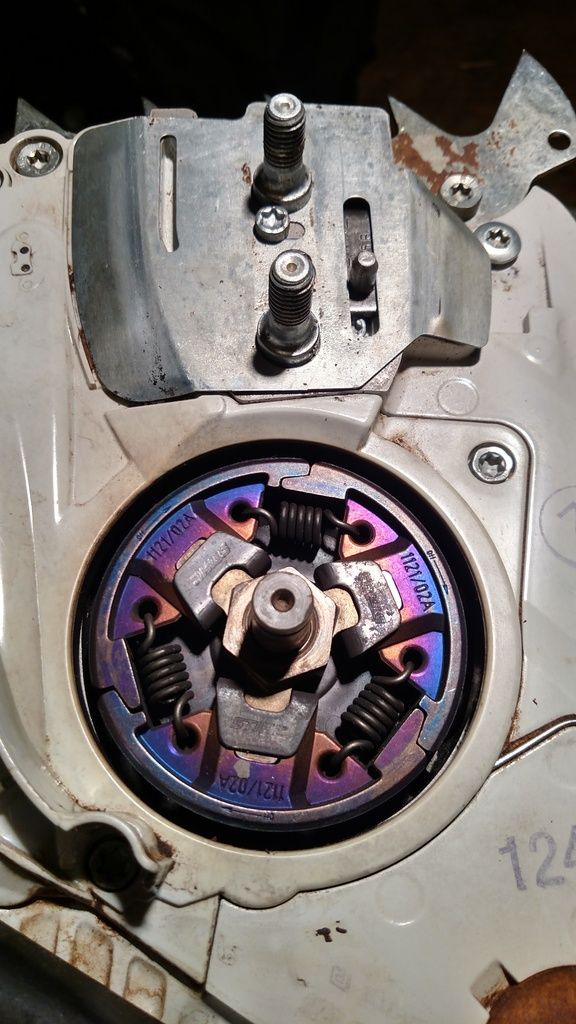

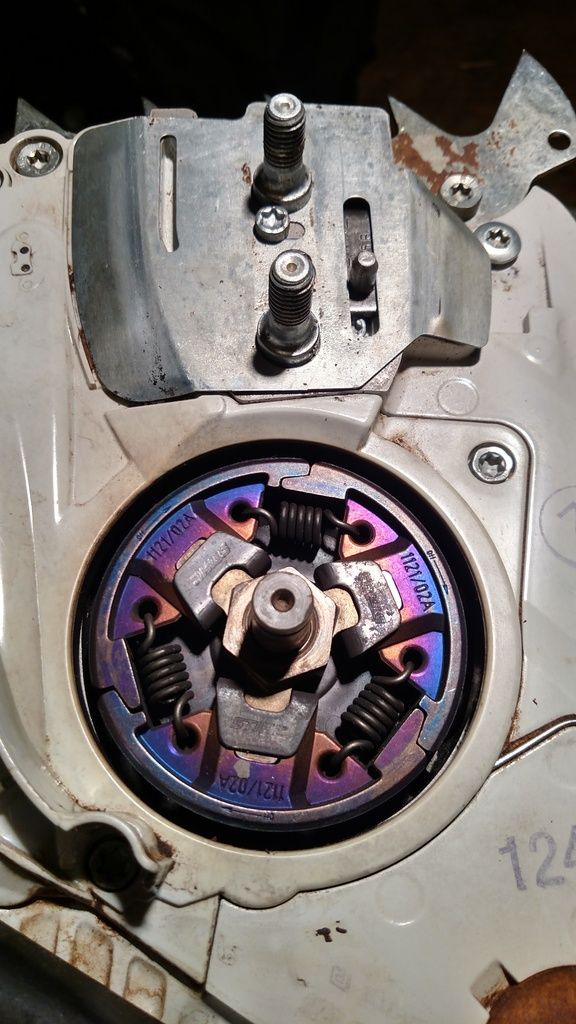

I have to say that I don't think I caused this. I let the saw idle in the start position for less than 30 seconds with the brake on, but it shouldn't cause this kind of heat. Chain brake operation seems to work just fine and I always roll the chain by hand after putting it back on just to be sure. I would like to think I take good care of my saws, keep them clean and always check this stuff. The clutch on my 261C is got some pretty blue colors to it but that saw seems to operate just fine as well, maybe I'm an idiot though!

Here is the 261, it's actually newer than the 661 by build date.

I could be the last to know this as well but I like how Stihl puts their colored tie straps on the right side for semi chisel chains, and the colored tie strap on the left side for chisel, actually I don't like that but just now noticed it after all these years...

I have to say that I don't think I caused this. I let the saw idle in the start position for less than 30 seconds with the brake on, but it shouldn't cause this kind of heat. Chain brake operation seems to work just fine and I always roll the chain by hand after putting it back on just to be sure. I would like to think I take good care of my saws, keep them clean and always check this stuff. The clutch on my 261C is got some pretty blue colors to it but that saw seems to operate just fine as well, maybe I'm an idiot though!

Here is the 261, it's actually newer than the 661 by build date.

I could be the last to know this as well but I like how Stihl puts their colored tie straps on the right side for semi chisel chains, and the colored tie strap on the left side for chisel, actually I don't like that but just now noticed it after all these years...