wavefreak

Addicted to ArboristSite

So I hit a nail:

This was on the last 18" on the last cut of my first milling project. The saw start making a noise like it was scraping leaves or bark or something. I checked underneath and it was clear so I tried a little more. When it didn't go away I checked the chain - duller than Forest Gump on Valium. The metal in the saw dust confirmed by suspicions.

Anyway, here's some more photos. This is the second stem from a 3 stem maple I had to take down. I'm pretty sure this would be firewood for most of you, but I figured learn on crap and know what I'm doing when I get to the good stuff.

I started with a freehand cut so I would have a place to nail my guide board

Guide board on ready to go

First bug

Bug damage

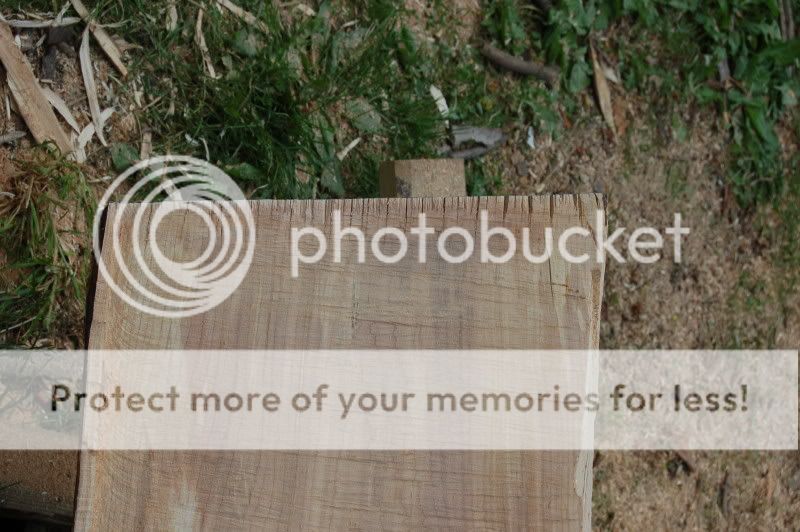

Checking. I cut several inches off of each end to get rid of the checking.

This was on the last 18" on the last cut of my first milling project. The saw start making a noise like it was scraping leaves or bark or something. I checked underneath and it was clear so I tried a little more. When it didn't go away I checked the chain - duller than Forest Gump on Valium. The metal in the saw dust confirmed by suspicions.

Anyway, here's some more photos. This is the second stem from a 3 stem maple I had to take down. I'm pretty sure this would be firewood for most of you, but I figured learn on crap and know what I'm doing when I get to the good stuff.

I started with a freehand cut so I would have a place to nail my guide board

Guide board on ready to go

First bug

Bug damage

Checking. I cut several inches off of each end to get rid of the checking.