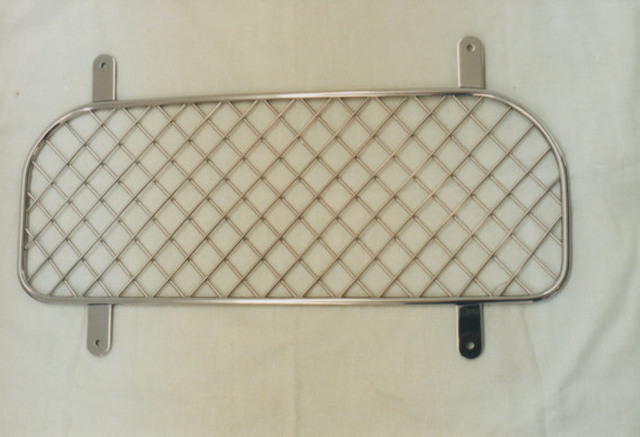

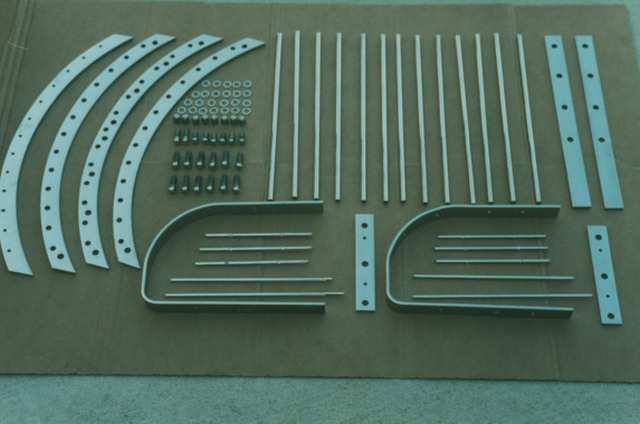

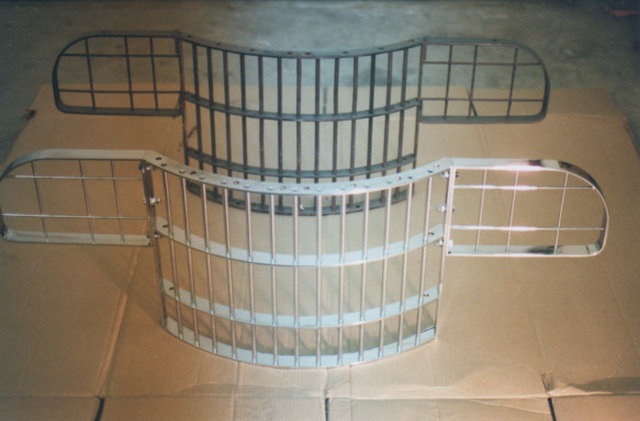

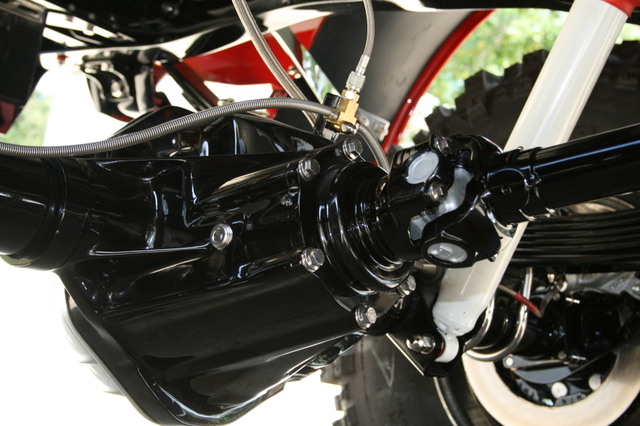

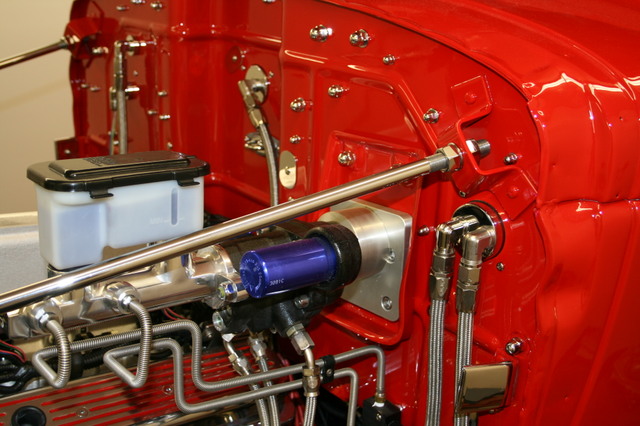

I started this project 13 years ago and figure I have close to 3000 hours in it. It a 1941 Dodge WC40 1/2 ton military 4x4. They made 275 of this model and it's the grandpa of the Power Wagons. I made a lot of the parts and most everything was smoothed, painted and bolted back together with polished stainless fasteners. Little by little it finally came together and did most everything here at home, including the paint. Even made that grill which is 1/4 X 2 inch stainless stock and cold bent.

You can see the build up pics and how stuff was done at : Albums By kevininohio - ImageEvent

Some people play video games, I like to make stuff when I'm not sawing for the boiler.

You can see the build up pics and how stuff was done at : Albums By kevininohio - ImageEvent

Some people play video games, I like to make stuff when I'm not sawing for the boiler.

I've been in the business for over 30 years and know exacly the time you have in that resto, hats off to you!

I've been in the business for over 30 years and know exacly the time you have in that resto, hats off to you!