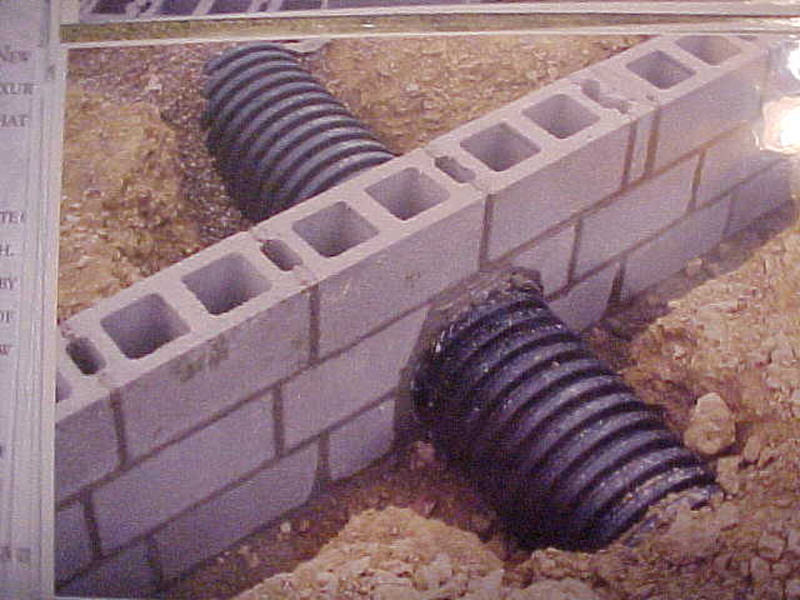

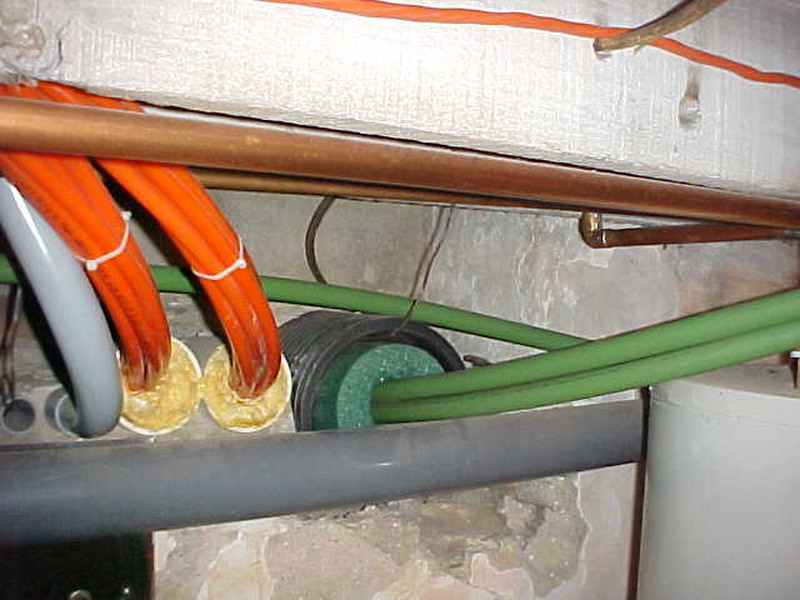

I installed logstor pipe in my former house a couple years ago. It's heavy duty stuff and does not flex much. You will not get it through 45 elbows, it needs a pretty wide radius to make a turn. I had to go under a pre existing sidewalk, then straight shot into the house through a cinder block foundation. I tunneled under the sidewalk, drilled some pilot holes in the blocks and chiseled out a wide enough hole without much of a problem. I also planned on using a PVC sleeve to protect the pipe as it went through the blocks, ended up using a formed piece of sheet metal instead. As it was, we had to anchor ratchet straps on rafters in the basement and ratchet the pipe through. We only got 3 or 4 feet into the basement, then tied into uninsulated pipe. I recommend just going into the house a few feet with the pipe, you don't want to have to drag it too far, it's bulky stuff to work with.

If you bury it a foot or two under the driveway concrete will not be a problem. There's no way you would compress the insulating foam enough to crush the pipe. Also if you go with logstor, forget about ever having to drag it through for repairs, you will never need to. The shell and foam is pretty tough stuff.