Chainsaw Jim

CJ Saws, LLC

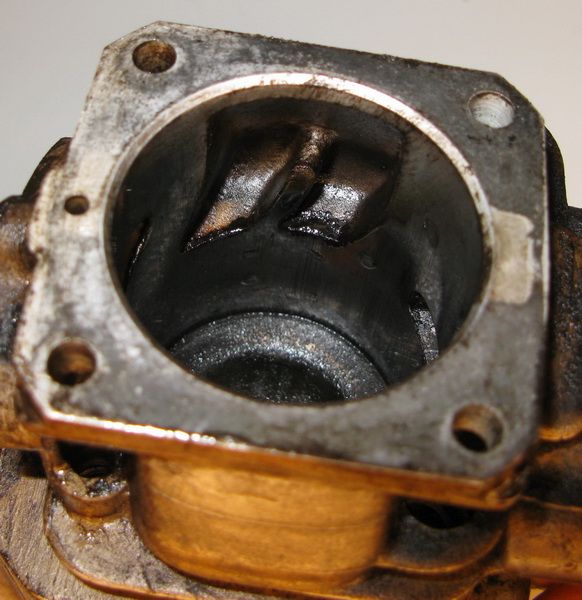

I'm trying to give you sound advice. Myself and others went round and round with the topic and quite a bit of testing was done. Windowing the piston does nothing, other than reducing base pressure.

You're really being way too defensive and immature. If you want to learn how to properly port a 372 "which you don't in any way shape or form" myself and others will be glad to help. Or you can dismiss us and stick your head in the sand. The choice is yours.

No offence but advise is not necessary here because I'm just experimenting with this particular idea. I never claimed to be an expert on port work, but contrary to your claim, I do know how to properly port a 372. This is no example of what you would consider as that, but I'm just sharing the experimenting I did on this saw with anyone interested in checking it out. I would have shared step by step through the course of the build but I didn't want comments like yours to alter my thought process on what I was doing.