Hey guys, I want to get some input and thoughts on this. I am going to build a new shop and I want to run radiant floor heat in it. Now I dont want to heat it to 80 degrees or anything, as long as I can warm it to 50-60 degrees, that all I want. It will be insulated. I was talking to a guy that has ran some under is floor. He had a 12,000 sq. foot shop, He dug a trench put some rock in it laid a seemless 1" water line, then finished filling the trench with rock. He then poured is slab on top of that. Now his line ran about 12 ft off the perimeter of the slab, and right down the middle. of the slab. He didnt have a whole bunch of lines running inside or under his slab. He claimed that he could heat the place to 65 degrees like this with. What are your thoughts on this. Or radiant heat for a shop in general. I will be using a outdoor wood furnace for the heating. Any input and thoughts would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Radiant floor heat for shop

- Thread starter Lagrue

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mysteryman896

ArboristSite Member

Ours is physically in the concrete. I was not there when the concrete was poured but the basic process that was done for my shop floor was; stone graded, wire grating laid (forget size guessing 2" squares, buffalo wire i think its called), tubing laid out on top and wire tied down, Then i THINK as they poured they lifted up on it or put spacers somewhere that concrete got under the wire grating and tube.

The tubes then went through pvc 90 degree sch 40 pipe where it came up through the concerte.

edit: oh i forgot, there was insulation between the stones and the tubing.

The tubes then went through pvc 90 degree sch 40 pipe where it came up through the concerte.

edit: oh i forgot, there was insulation between the stones and the tubing.

Last edited:

mysteryman896

ArboristSite Member

i will try and dig up a picture or two of the tubing stitting on the stone. we have a 4 zone mainfold but would have to manually shut a zone off, we didnt put in thermostatic valves or anything.

mysteryman896

ArboristSite Member

tubing

View attachment 212754

after its all hooked up

View attachment 212755

and the boiler for good measure, old picture before i was finished with that room.

View attachment 212756

View attachment 212754

after its all hooked up

View attachment 212755

and the boiler for good measure, old picture before i was finished with that room.

View attachment 212756

Our garage (which also doubles as my shop) has in-floor heat run off a nat gas boiler. It is nice in that your feet are warm and it's VERY nice when you have to crawl under the vehicle. The only downfall is that the response time is quite long if you want to bump the temp up. I'll keep the t-stat at around 52° during the week but if I think I'll be working out there on the weekend I have to remember to adjust the t-stat on Friday morning so it's up to the low 60s by Saturday morning.

I also believe you can run lower temps overall because the radiant type heat just "feels" warmer. Remember that with radiant heat the air near floor will be warmer than the air near the ceiling.

Also remember that if you think you'll be needing to anchor anything to the floor to either mark the locations ahead of time and avoid putting lines there or put the anchors in when you pour the slab. In other words, you won't want to drill into the floor later on and risk hitting a line.

Lastly, don't forget the floor drain!!

I also believe you can run lower temps overall because the radiant type heat just "feels" warmer. Remember that with radiant heat the air near floor will be warmer than the air near the ceiling.

Also remember that if you think you'll be needing to anchor anything to the floor to either mark the locations ahead of time and avoid putting lines there or put the anchors in when you pour the slab. In other words, you won't want to drill into the floor later on and risk hitting a line.

Lastly, don't forget the floor drain!!

Sounds like your buddy is heating the ground and the shop. You're in a fairly mild climate, around here a minimum of 2" high density foam is recommended under the concrete. Don't know if your shop is insulated or not but decent insulation and a warm slab shouldn't require much of a fire in your climate.

Garmins dad

Addicted to ArboristSite

That other fella must have some big cold spots in his floor.. You will want a floor drain.. Not sure is snow on your equipment is a problem for you. BUT if you do get it there and park inside you will want some kind of de humidifier. I went this route. road crush packed down, sand, insulation, rebar on two foot squares, wire mesh that is 4 inch square, pex lines. under the rebar are little hold up stands so the concrete gets under the rebar. i have a 8 inch slab due to the equipment i bring in to work on. This county wouldn't allow a drain :msp_mad: so i get water on the floor but i squeege it out.

A great resource and one of my other "haunts"

The Garage Journal in the Heating/AC section of the forum.

PS - not to hijack but does anyone use a wood stove INSIDE a garage shop with cars/chemicals etc or it this a really bad plan?

The Garage Journal in the Heating/AC section of the forum.

PS - not to hijack but does anyone use a wood stove INSIDE a garage shop with cars/chemicals etc or it this a really bad plan?

mga

wandering

tubing

View attachment 212754

after its all hooked up

View attachment 212755

and the boiler for good measure, old picture before i was finished with that room.

View attachment 212756

nice set up!

Hey guys, I want to get some input and thoughts on this. I am going to build a new shop and I want to run radiant floor heat in it. Now I dont want to heat it to 80 degrees or anything, as long as I can warm it to 50-60 degrees, that all I want. It will be insulated. I was talking to a guy that has ran some under is floor. He had a 12,000 sq. foot shop, He dug a trench put some rock in it laid a seemless 1" water line, then finished filling the trench with rock. He then poured is slab on top of that. Now his line ran about 12 ft off the perimeter of the slab, and right down the middle. of the slab. He didnt have a whole bunch of lines running inside or under his slab. He claimed that he could heat the place to 65 degrees like this with. What are your thoughts on this. Or radiant heat for a shop in general. I will be using a outdoor wood furnace for the heating. Any input and thoughts would be appreciated.

When we installed it the loops were all cut to the same length, the 1/2" pex was zip tied to 6"x6" concrete mesh, with no overlaps. The pex was run in 6" spacing from the perimeter to the 6' mark. Then 12" spacing to 10', with the rest on 18" spacing, the mesh rested on 2" standoffs, with foamboard as insulation. We also had no drains and squeegeed the water out, and humidity was the one draw back I can think of with it. We worked on trailers and they would come in with the wheel wells filled solid with ice, so we tried to get them in the shop late in the day so the would melt off for the following day. The first year the boiler ran out of fuel a couple of times over the weekend and it took about four or five hours to get back up to temp, the three zones were set at 50,50and 52 degrees. My personal opinion is its the only way to heat a shop, we had 7- 14'x14' overhead doors, we could and did (to get rid of moisture) open them all at -15 for a few minutes and ten minutes after closing them you would never know they had been open.

mysteryman896

ArboristSite Member

nice set up!

thanks. its 3 yrs in the making and im still not done. I need to put in an exhaust fan to push out the smoke when i load the boiler. there is a wall so the smoke stays in the end bay and slowly moves out the bay door but its still annoying. i think im going to wire a timer switch in so i can turn it on and walk away. otherwise it will end up getting left on all the time. that bay isnt heated so im not worried about heat loss from the fan. I also need to put the bathroom in, and run airline throughout. Plus lots of other odds and ends that improve things as they come up.

If this shop is going to ANY heavier stuff, even if it's in the back of your mind, go with 6 inches minimum on the floor thickness. Another important thing is to remember is that if your slab shifts from a crack your tubing will be junk as it will be pinched or broke. I can NOT stress enough to go overkill on building it. To me, it's not overkill, it's avoiding a future problem.

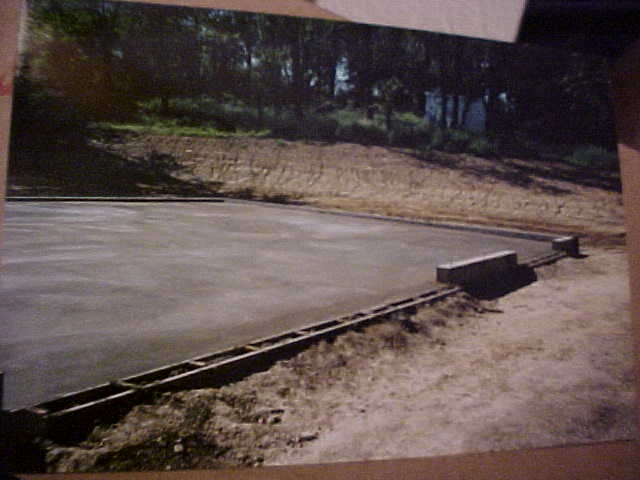

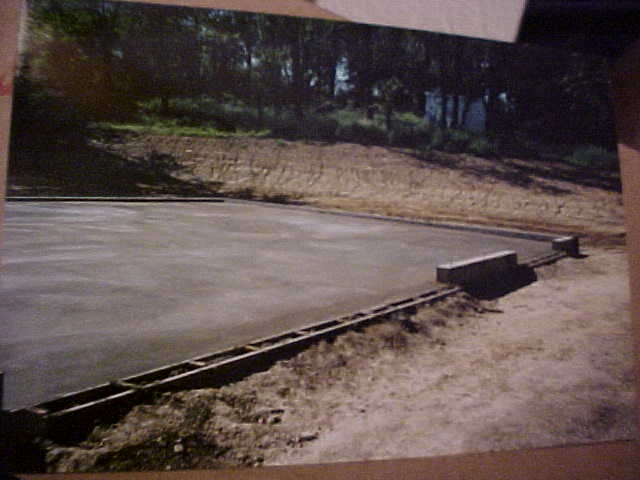

Here is my install. This was about 8 years ago and had absolutely NO problems with it. I did all the excavation and construction on it and took care to not disrupt the base for future settling issues. 4 inches of pea gravel, insulation in rolls with vapor barrier built into it. The joints had tape on both sides. Around the edges I used thick styrafoam with 45 degree angles cut at the top edges so you can't tell it's there when finished. It has not cracked anywhere yet.

Personally I do not like road mesh as it's always on the bottom. I use 1/2" rebar 16 on center and wire tied together. This makes a great grid to attach you hose. I used simple plastic Zip ties with no problems. I found a company that makes poly rebar chairs and they are sweet. They make them in various sizes every 1/2" . They snap onto the rebar and hold it in the center, or where ever you want it as they have nice round flat bases.

I would also recommend doing a pressure test BEFORE pouring cement and keeping some pressure on it while pouring. have splices ready in case of a boo boo and if you hit it. That way the air bubbles will show. This is another reason I do NOT like mesh as you have to stick an object into the concrete to pull up the mesh. Not worth the risk to me.

Some of the pics are picture of picture so the quality isn't very good, but the best I cab do at the moment.

Also be REAL careful with your drainage. You don't want to have underground water problems so at least tile around the outside to give it a place to go.

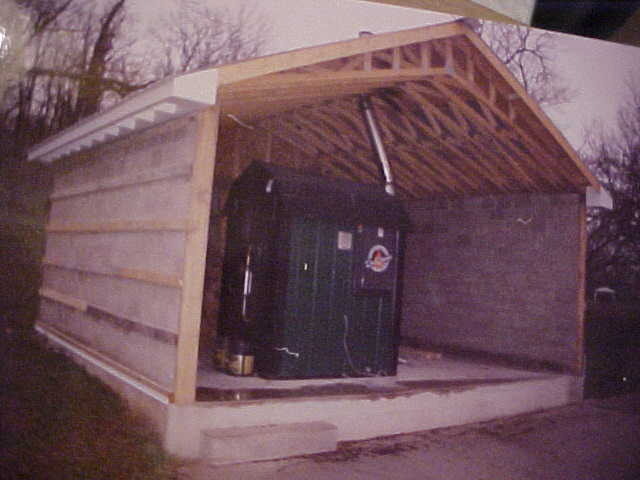

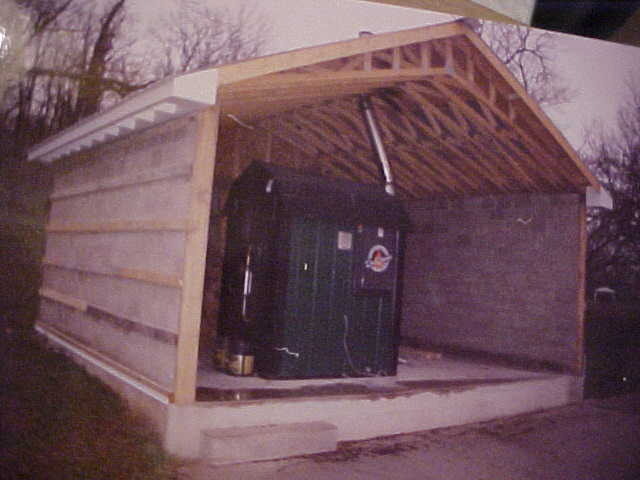

I would NOT recommend a boiler in living space or some place you work. Opening the door at the wrong time will smoke you out and why take up shop space for wood storage? I built a building for the boiler and a years wood storage(13 cord). It's 20' X 20' with cathedral trusses so I can lift it out if need be with overhead boom. Keeps me AND the wood dry. Put in a big exhaust fan to get smoke out but if you watch your burn cycles it's not too bad. I laid concrete block around 3 sides and filled the cores with concrete, running a 1/2 rebar in every other core. I can stack the wood up against the walls with no worries. No termite problems with this either.

On the open side shown above I stick framed sections and used screws to put it all together. Would take a couple hours to get it open and the walk in door stays. Nailed 2x4's on the outside to screw metal siding on to match the other buildings.

Here is a finished pic.

Another thing to consider is to make the shop a separate zone using a heat exchanger. Reason being, that if for some reason you don't want to heat it all the time, you can run antifreeze in that zone only. Your tubing won't freeze and burst with the antifreeze if you opt for not heating it. Separate zone will save you a ton as the antifreeze is not cheap. I run mine all winter long so it's not an issue for me but something to think about.

Here is my plumbing layout. Water heater is out of the pic on the right.

There's a lot of things to think about when doing this. If you are planning to stay at this residence for a while, do it right.

Here is my install. This was about 8 years ago and had absolutely NO problems with it. I did all the excavation and construction on it and took care to not disrupt the base for future settling issues. 4 inches of pea gravel, insulation in rolls with vapor barrier built into it. The joints had tape on both sides. Around the edges I used thick styrafoam with 45 degree angles cut at the top edges so you can't tell it's there when finished. It has not cracked anywhere yet.

Personally I do not like road mesh as it's always on the bottom. I use 1/2" rebar 16 on center and wire tied together. This makes a great grid to attach you hose. I used simple plastic Zip ties with no problems. I found a company that makes poly rebar chairs and they are sweet. They make them in various sizes every 1/2" . They snap onto the rebar and hold it in the center, or where ever you want it as they have nice round flat bases.

I would also recommend doing a pressure test BEFORE pouring cement and keeping some pressure on it while pouring. have splices ready in case of a boo boo and if you hit it. That way the air bubbles will show. This is another reason I do NOT like mesh as you have to stick an object into the concrete to pull up the mesh. Not worth the risk to me.

Some of the pics are picture of picture so the quality isn't very good, but the best I cab do at the moment.

Also be REAL careful with your drainage. You don't want to have underground water problems so at least tile around the outside to give it a place to go.

I would NOT recommend a boiler in living space or some place you work. Opening the door at the wrong time will smoke you out and why take up shop space for wood storage? I built a building for the boiler and a years wood storage(13 cord). It's 20' X 20' with cathedral trusses so I can lift it out if need be with overhead boom. Keeps me AND the wood dry. Put in a big exhaust fan to get smoke out but if you watch your burn cycles it's not too bad. I laid concrete block around 3 sides and filled the cores with concrete, running a 1/2 rebar in every other core. I can stack the wood up against the walls with no worries. No termite problems with this either.

On the open side shown above I stick framed sections and used screws to put it all together. Would take a couple hours to get it open and the walk in door stays. Nailed 2x4's on the outside to screw metal siding on to match the other buildings.

Here is a finished pic.

Another thing to consider is to make the shop a separate zone using a heat exchanger. Reason being, that if for some reason you don't want to heat it all the time, you can run antifreeze in that zone only. Your tubing won't freeze and burst with the antifreeze if you opt for not heating it. Separate zone will save you a ton as the antifreeze is not cheap. I run mine all winter long so it's not an issue for me but something to think about.

Here is my plumbing layout. Water heater is out of the pic on the right.

There's a lot of things to think about when doing this. If you are planning to stay at this residence for a while, do it right.

Last edited:

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 5

- Views

- 954

- Replies

- 2

- Views

- 2K