RPM

ArboristSite Operative

I was going to post this into parrisw's thread, but didn't want to take away from what is a really nice piece of work. This will probably lead into other stories anways which ends up hijacking the original thread maker. I guess any mistake that I've made that someone else can avoid making by reading this is probably worthwile. This ties into WS's comments/ post regarding spiral cutters and template routing and parrisw's adirondak chair (www.arboristsite.com/showthread.php?p=1206328#post1206328).

That body and head of that little pony is made of 2 - 3/4" outside pieces with a 1 1/2" piece sandwiched in between. I glued all 3 pieces together for the body and head (they are seperate and go together later), roughed out on the bandsaw and then fihished up with the template and router.

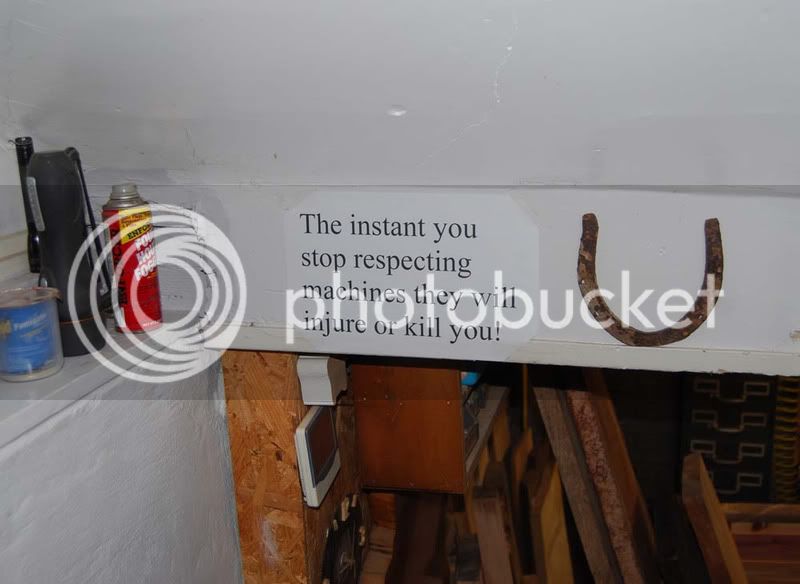

Long story short, the head piece is relatively smaller than the body and has lots more tight curves - most of which go across the grain. The pony is milled from Douglas fir and this particular piece has some crazy sumer wood in it - dense and very hard. I do not have a variable speed router (mistake #1 - big bits shouldn't be run at 22K rpm)....mistake #2 big bit at high speeds....mistake #3.... should have had the work pices clamped to a sled of some sort to keep my hands away. At any rate....I probably pushed the work piece into the bit a tad fast, the bit caught the that nice dense end grain and promptly spun it of my hands (which caught a my thumb on the way by) and threw it down the length of the shop ...about 25'. Thought I cut my thumb off but it was just the ponies head hitting it at 100mph. My girls love it and my thumb is still numb 2 years later.

I still don't have a variable speed router but did invest in a couple of Desatco toggle / hold down clamps. That sprial cut bit looks worth investigating further by buying one - xmas is coming. I don't template route anything that puts my hands closer than 1' away from the bit without clamping it to a sled now....and yes the wood is CSM:greenchainsaw:

That body and head of that little pony is made of 2 - 3/4" outside pieces with a 1 1/2" piece sandwiched in between. I glued all 3 pieces together for the body and head (they are seperate and go together later), roughed out on the bandsaw and then fihished up with the template and router.

Long story short, the head piece is relatively smaller than the body and has lots more tight curves - most of which go across the grain. The pony is milled from Douglas fir and this particular piece has some crazy sumer wood in it - dense and very hard. I do not have a variable speed router (mistake #1 - big bits shouldn't be run at 22K rpm)....mistake #2 big bit at high speeds....mistake #3.... should have had the work pices clamped to a sled of some sort to keep my hands away. At any rate....I probably pushed the work piece into the bit a tad fast, the bit caught the that nice dense end grain and promptly spun it of my hands (which caught a my thumb on the way by) and threw it down the length of the shop ...about 25'. Thought I cut my thumb off but it was just the ponies head hitting it at 100mph. My girls love it and my thumb is still numb 2 years later.

I still don't have a variable speed router but did invest in a couple of Desatco toggle / hold down clamps. That sprial cut bit looks worth investigating further by buying one - xmas is coming. I don't template route anything that puts my hands closer than 1' away from the bit without clamping it to a sled now....and yes the wood is CSM:greenchainsaw:

hope it gets better soon!

hope it gets better soon!