If you do not have a chain tensioner you will have a hell of a time using it

Lets just assume that you do and your setting up for the first time.

with grinding head in the up position (motor OFF).

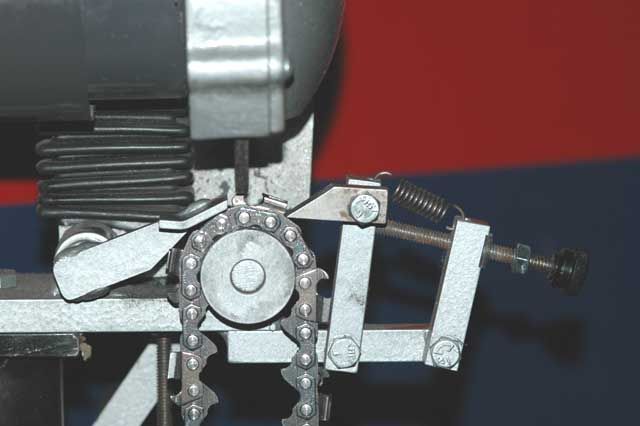

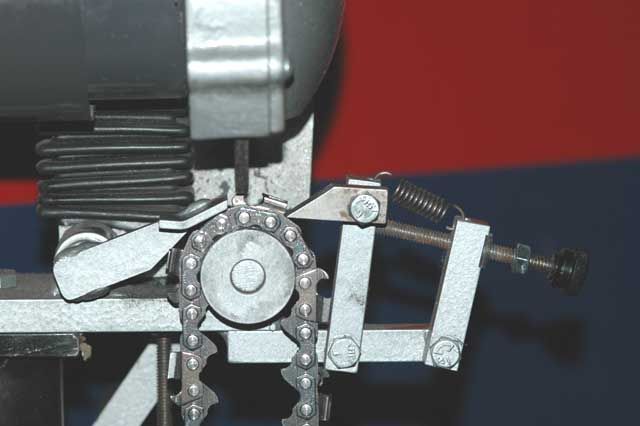

Put your chain on and properly tension it. I always start with the tensioner pulley about 1'-2' below the chain tensioner making sure the chain is running true pull up on the Handel and put he chain in the tensioner. turn the crank making sure nothing is binding.

Now we adjust the cam

lower the grinding head (motor OFF) turn the depth gauge adj. (the big knob on the top) so that it clears the tooth completely.Turn chain to be sure.

Now adj. the cam by turning the knob on the bottom until the grinding head starts lifting when you crank the crank adj. this so that it just clears the tooth and hits nothing, (if it hits you need to turn the top knob some more.)

OK now turn the motor on line the wheel up with a raker slowly bring the depth gage knob down until you just make a spark. As you turn the chain (Yes with the crank) the cam will lift the grinding head over the tooth and hit the raker as you go around.

Now I always lift the head and turn the tooth down so that I can check it with a gage. (if you have the chain tight enough you can do this)adj.from their.

Now don't try to make it sound like a Gatling gun but you can go at a half-fast speed and do a good job. Some guys will even go back and forth on every raker until they stop making sparks.

Hope this made some kind of sense

OK now I gotta go grind on a 372 Barrel

adj. this so that it just clears the tooth and hits nothing, (if it hits you need to turn the top knob some more.)

adj. this so that it just clears the tooth and hits nothing, (if it hits you need to turn the top knob some more.)