AndyR

ArboristSite Operative

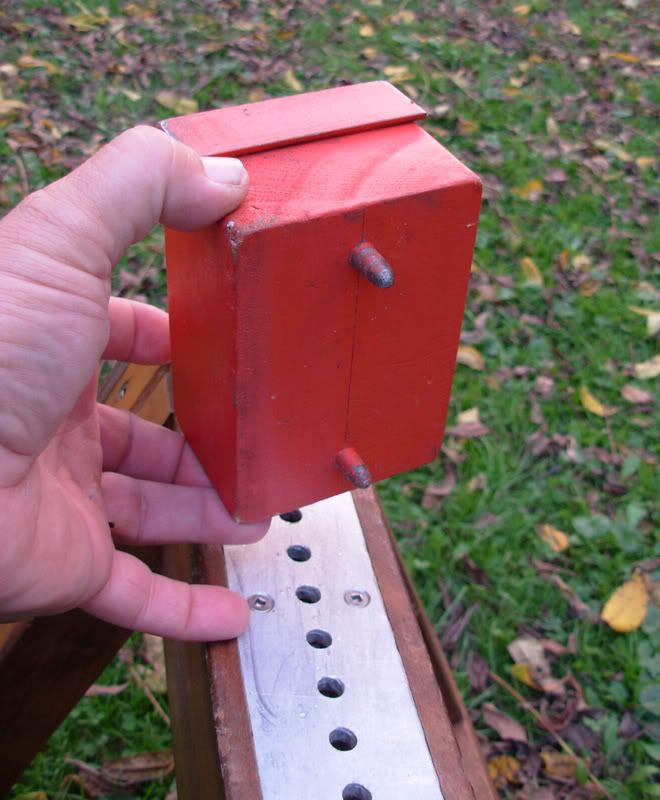

It was a really nice day here, around 74 degrees, so I decided to mill the best crotch piece from the big walnut and two shorter cherry logs. The walnut crotch was pretty nice but the figure didn't go very wide. One of the cherry logs was a crotch as well and it had a little figure but nothing fantastic. I'll be doing a lot of trimming and working around holes and bad sections on these cherry boards when it comes time to use them, but it's still better than wasting them. I've got to take the time to build a pair of sawhorses, my back is tired

Each time I use the RipSaw goes a little better, though.

Andy

Each time I use the RipSaw goes a little better, though.

Andy

Very Nice............looks as if have a good size log to mill.

Very Nice............looks as if have a good size log to mill.