You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you building with your milled wood? merged

- Thread starter stonykill

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Can8ianTimber

ArboristSite Operative

Here are a couple of pictures of the leanto I built off the shop. The shop was built with lumberstore sticks but the leanto was 100% homesawn lumber. Nothing fancy like the other structures you guys have built but it serves its purpose and I think it looks cool being all rough sawn. I have put a roof on it now but I don't have any pictures of it with the roof on.

BlueRider

ArboristSite Guru

- Joined

- Feb 7, 2007

- Messages

- 550

- Reaction score

- 125

Fallingwater chair

I don't post pics of my work very often but since I enjoy seeing pics of everyone elses work I thought I should shre some pics of a recent piece. This is made from some claro walnut I milled a couple of years ago. I had been milling a lot of claro from a nearby orchard when I was offered a large claro walnut log two blocks from my house. It was a real "when it rains it pours" kind of thing. I shared the wood from that log with a friend wo helped me mill it and I still ended up with six 2 1/4" slabs with the biggest being 36" wide and 10' long. I used two slabs to make two of these chairs. All the parts came from one slab except one of the seats. I actually cut the seat for one of the slabs out of the center of one slab. that may sound wa####ll but I think the results prove otherwise. Besides I have over 100 slabs of claro walnut.

The back was made by cutting four 'boomerang' shaped pieces out of a 2" slab and turning them 90* and gluing them together. I then cut the giant "s" shape on my bandsaw. The carving on the back side was done by hand with a gouge. It is a pattern I have used several times before and really like even though it took two full 8 hour days to carve. the legs are turned on my lathe without the aid of a duplicator and the seat was carved with a 4 1/2" sanding disc on an angle grinder and then hand sanded starting with 50 grit and finished with 320 grit. The finish is one coat of tung oil followed by three coats of general HP poly and then rubbed out and coated with past wax.

I just sold this at a show in San Francisco but I had to bring it home to refinish the seat. A woman sat in it with huge conchos on her back pockets and put some rather deep gouges in the seat. Even so I am happy to have made such a nice sale in this economy and the buyer is being very understanding about me having to refinish the seat before I can deliver it.

I don't post pics of my work very often but since I enjoy seeing pics of everyone elses work I thought I should shre some pics of a recent piece. This is made from some claro walnut I milled a couple of years ago. I had been milling a lot of claro from a nearby orchard when I was offered a large claro walnut log two blocks from my house. It was a real "when it rains it pours" kind of thing. I shared the wood from that log with a friend wo helped me mill it and I still ended up with six 2 1/4" slabs with the biggest being 36" wide and 10' long. I used two slabs to make two of these chairs. All the parts came from one slab except one of the seats. I actually cut the seat for one of the slabs out of the center of one slab. that may sound wa####ll but I think the results prove otherwise. Besides I have over 100 slabs of claro walnut.

The back was made by cutting four 'boomerang' shaped pieces out of a 2" slab and turning them 90* and gluing them together. I then cut the giant "s" shape on my bandsaw. The carving on the back side was done by hand with a gouge. It is a pattern I have used several times before and really like even though it took two full 8 hour days to carve. the legs are turned on my lathe without the aid of a duplicator and the seat was carved with a 4 1/2" sanding disc on an angle grinder and then hand sanded starting with 50 grit and finished with 320 grit. The finish is one coat of tung oil followed by three coats of general HP poly and then rubbed out and coated with past wax.

I just sold this at a show in San Francisco but I had to bring it home to refinish the seat. A woman sat in it with huge conchos on her back pockets and put some rather deep gouges in the seat. Even so I am happy to have made such a nice sale in this economy and the buyer is being very understanding about me having to refinish the seat before I can deliver it.

That is one slllllick piece of furniture BR -

BIG JAKE

Let’s go Brandon!

Suuuweeeeet!

Beautiful chair Robin! I would have come and seen it in person had I not hurt my back.

jerry-

jerry-

mtngun

Addicted to ArboristSite

I threw a few more boards on the woodshed today.

I threw a few more boards on the woodshed today.

That's going to be one stout shed. Keep those pic's coming.

jerry-

glennschumann

ArboristSite Operative

Thanks

Thanks for the complements and comments! I'm familiar with the cupping of boards, and I always think about that when I see wooden decks and porches with boards placed as "frowns" that warp / cup to hold water when it rains.

The boards I used for the top literally left met about 1/4" extra width when I glued them up with live edges... not much wiggle room, and yes, the pretty side is up. The wood sat in the rafters of my garage for about 3 years, so I was fairly certain the movement was going to be minimized. After I rough cut and milled the top board, it had several months in my shop to acclimate and has remained flat ever since. I get to see it every time I visit my sister and little niece. It sits in their front hall. : )

I wouldn't have quoted such an old post but I checked your profile and see that you still come around. Beautiful bench! And that joinery you used blows my mind. I've been a custom cabinetmaker for almost two decades and that is among the best joinery I've seen.

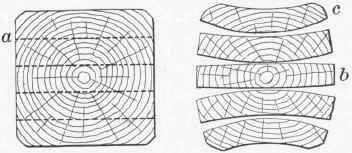

I do have one thing that you might watch for in the future when gluing up wide planks like this one. Look at the ends of the boards. See how the growth rings are turning in what looks like a "frown"? I call those "smiles" and "frowns" It's not crucial on a plank the size of yours - around 12 inches or so - but when gluing up it's best to alternate your "smiles" and "frowns". This will help your lumber from cupping in the future. I'm sure you picked the face of your board by the cosmetic appearance. If you ever do a very large plank this way and fail to keep in mind how the wood cups you can run into problems rather quickly.

As you can see from the picture below, you can look at the ends of a board and determine how it will cup. Closer to the center there is very little cupping but the wood will tend to try to cup on the top and bottom, becoming a bit thicker in the middle. I'd say after the amount of time since your project was completed you have a distinct upward bow down the middle like the board right below the middle one in the pic.

Again, beautiful work!

Thanks for the complements and comments! I'm familiar with the cupping of boards, and I always think about that when I see wooden decks and porches with boards placed as "frowns" that warp / cup to hold water when it rains.

The boards I used for the top literally left met about 1/4" extra width when I glued them up with live edges... not much wiggle room, and yes, the pretty side is up. The wood sat in the rafters of my garage for about 3 years, so I was fairly certain the movement was going to be minimized. After I rough cut and milled the top board, it had several months in my shop to acclimate and has remained flat ever since. I get to see it every time I visit my sister and little niece. It sits in their front hall. : )

mtngun

Addicted to ArboristSite

Mini-milling 8x8's at home.

A corner chisel hasn't shown up yet, plus the handle broke on the Bailey's slick. The metal part of the slick works fine, but the handle seems to be some kind of Taiwanese softwood.

A few more boards and posts installed.

A corner chisel hasn't shown up yet, plus the handle broke on the Bailey's slick. The metal part of the slick works fine, but the handle seems to be some kind of Taiwanese softwood.

A few more boards and posts installed.

smokinj

Addicted to ArboristSite

Mini-milling 8x8's at home.

A corner chisel hasn't shown up yet, plus the handle broke on the Bailey's slick. The metal part of the slick works fine, but the handle seems to be some kind of Taiwanese softwood.

A few more boards and posts installed.

Starting to look like a brick crap house! Nice I could live in there...lol when your done.

mtngun

Addicted to ArboristSite

I ran out of doug fir logs so I had to make a couple of 8x8's out of ponderosa, to finish the job. The pine timbers were placed on the interior wall, where they won't be exposed to weather. They should work OK there.

A major milestone was reached today as I finished erecting all the vertical posts.

Still lots and lots of work yet to get a roof on before winter. We've already had our first frost of the season, so the clock is definitely ticking.

A major milestone was reached today as I finished erecting all the vertical posts.

Still lots and lots of work yet to get a roof on before winter. We've already had our first frost of the season, so the clock is definitely ticking.

mtngun

Addicted to ArboristSite

Worked on floor joists today.

Coming along noicely!

The surrounds looks like the building is isolated on it's own on a prairie, I'm intrigued as to what other buildings or plants/forest are near by?

The surrounds looks like the building is isolated on it's own on a prairie, I'm intrigued as to what other buildings or plants/forest are near by?

Brmorgan

Addicted to ArboristSite

- Joined

- Apr 22, 2008

- Messages

- 3,248

- Reaction score

- 348

That's coming along quite nicely.

I'm thinking with your lathe skills you should be able to fab up a new handle for that chisel without too much trouble. Find some nice hard apple or something.

Those Pine posts should be just fine; definitely for your lifetime anyway if maintained. Around here there are numerous abandoned cabins and homesteads out in the middle of nowhere that were built out of Lodgepole pine the better part of a century ago, and are still standing (though mostly not usable) even being left to the elements for decades. There are houses much older than that as well, that have been taken care of and lived in that are still in great shape.

I'm thinking with your lathe skills you should be able to fab up a new handle for that chisel without too much trouble. Find some nice hard apple or something.

Those Pine posts should be just fine; definitely for your lifetime anyway if maintained. Around here there are numerous abandoned cabins and homesteads out in the middle of nowhere that were built out of Lodgepole pine the better part of a century ago, and are still standing (though mostly not usable) even being left to the elements for decades. There are houses much older than that as well, that have been taken care of and lived in that are still in great shape.

Last edited:

mtngun

Addicted to ArboristSite

Yes, this area is a mix of prairie, forest, and canyons. Wildfires and a harsh climate make it difficult for trees to establish except on the shady north slopes.The surrounds looks like the building is isolated on it's own on a prairie, I'm intrigued as to what other buildings or plants/forest are near by?

Livestock will stomp and eat pine seedlings, so few trees will grow unless you fence out the livestock. The ranchers constantly bulldoze small trees and shrubs to make room for more grass.

I've planted over a thousand tree seedlings on my property, but it'll be another decade before they show up in the photos.

I may have already posted these pics ?

A neighbor's back yard, looking across the head of Getta canyon

View from my back yard. The trees on the horizon are the forest where I go woodcutting.

Ah yes, I remember those pics but couldn't connect the two.

Fantastic views!

Maybe you've said before, but how long does the snow last?

Fantastic views!

Maybe you've said before, but how long does the snow last?

mtngun

Addicted to ArboristSite

It varies quite a bit from year to year.Maybe you've said before, but how long does the snow last?

In an average year, snow will stay on the ground from mid-November to late March.

Similar threads

- Replies

- 27

- Views

- 4K

- Replies

- 252

- Views

- 18K

- Replies

- 17

- Views

- 4K

- Replies

- 4

- Views

- 1K