ssm1699

ArboristSite Operative

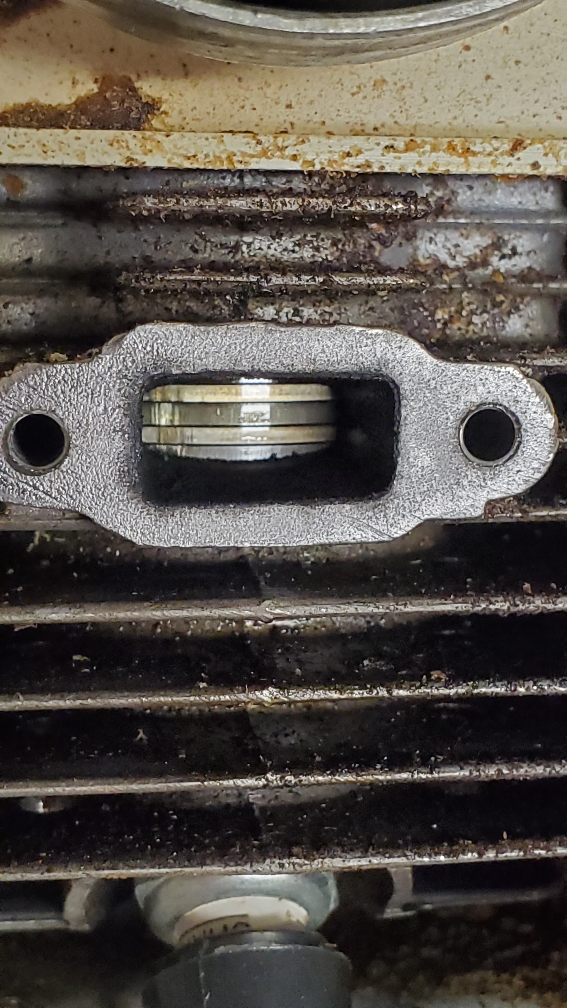

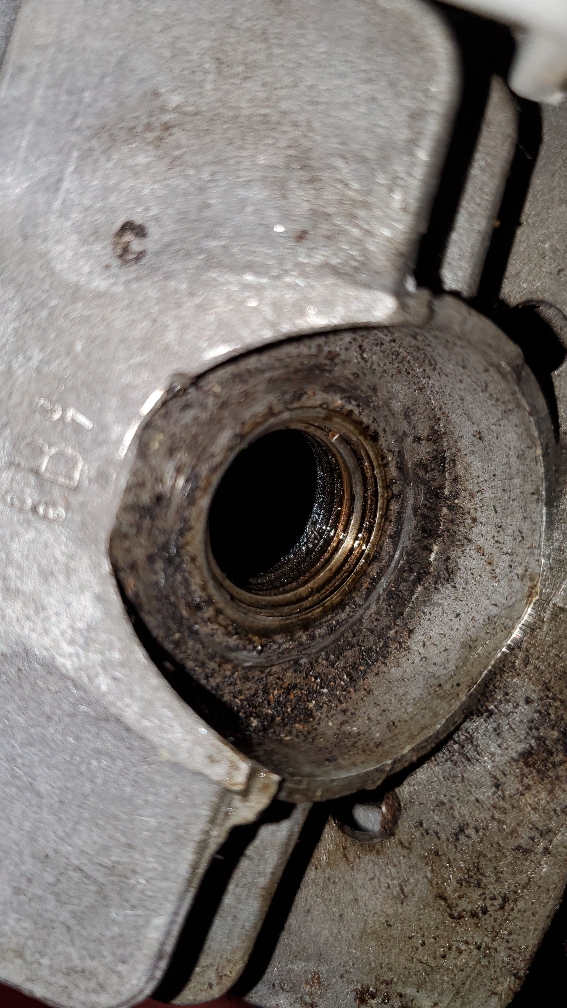

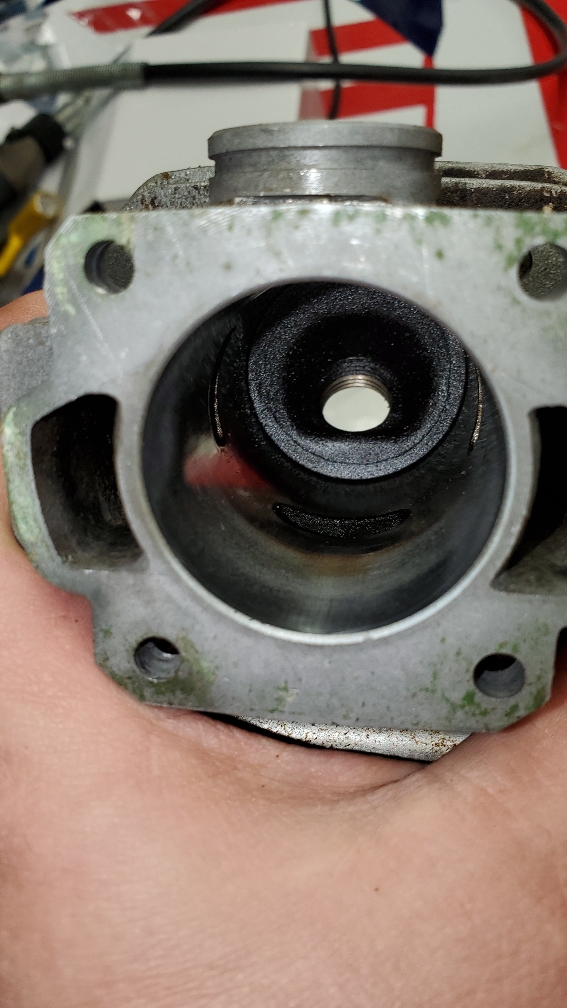

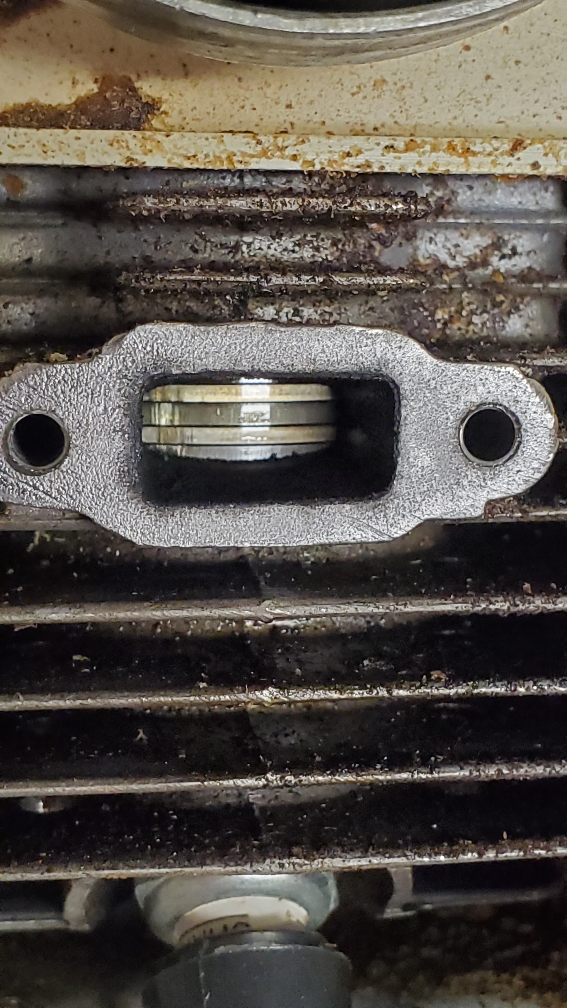

Ok, so I have been going through all my saws and servicing them, amongst other things. I have had my Stihl 020AV for several years and finally decided to do a comp test/check the piston through the exhaust port. The only trouble I have had with this saw in the time I have had it, was a melted pulse hose or fuel line, can't remember. Got it as a non-runner and needed a carb rebuild. The comp test gave me 125 psi and the following picture is what the piston looks like through the exhaust port. Would you guys pull it apart or just run it? Not a hard starter and has had plenty of power since I got it, with a 14" hard nose stihl bar and 1/4" pitch chain. The plug looked like it could be a hair richer, so I opened the adjustments a tad. No vac leaks or pressure leaks, that I have found.

Sent from my SM-G973U using Tapatalk

Sent from my SM-G973U using Tapatalk