Mastermind

Work Saw Specialist

Here's some pics of a project I'm currently tinkering on......

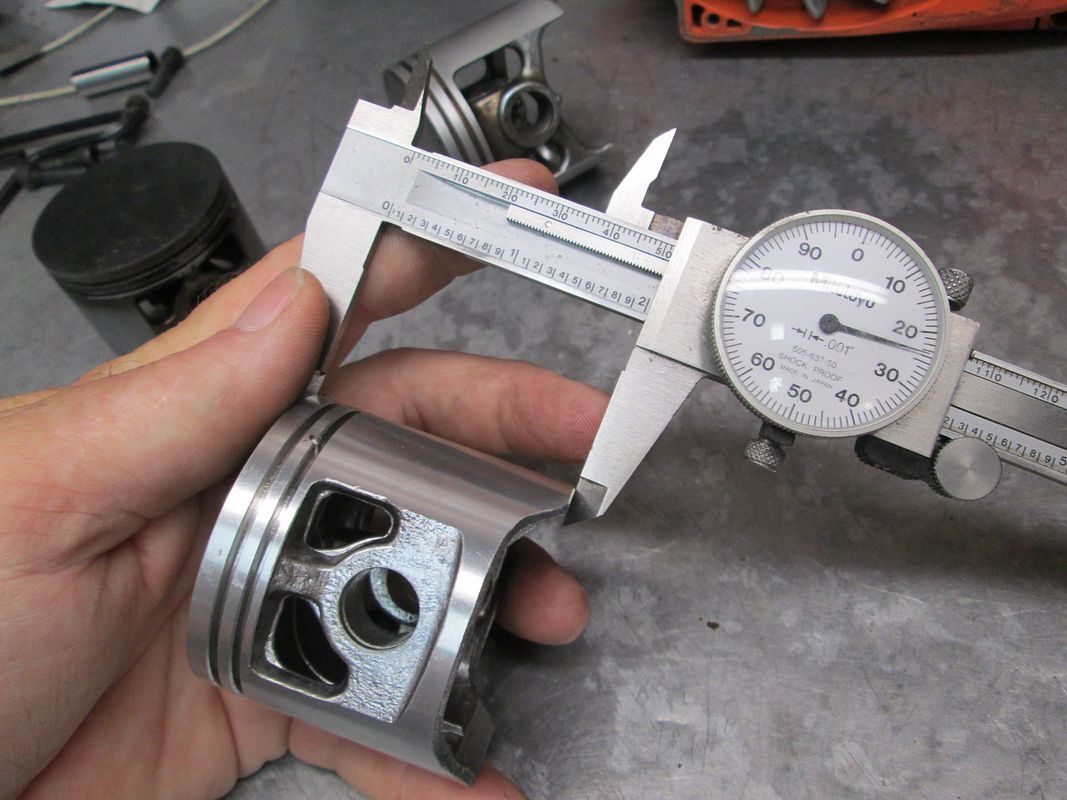

This is a KS 2100XP full skirt piston.

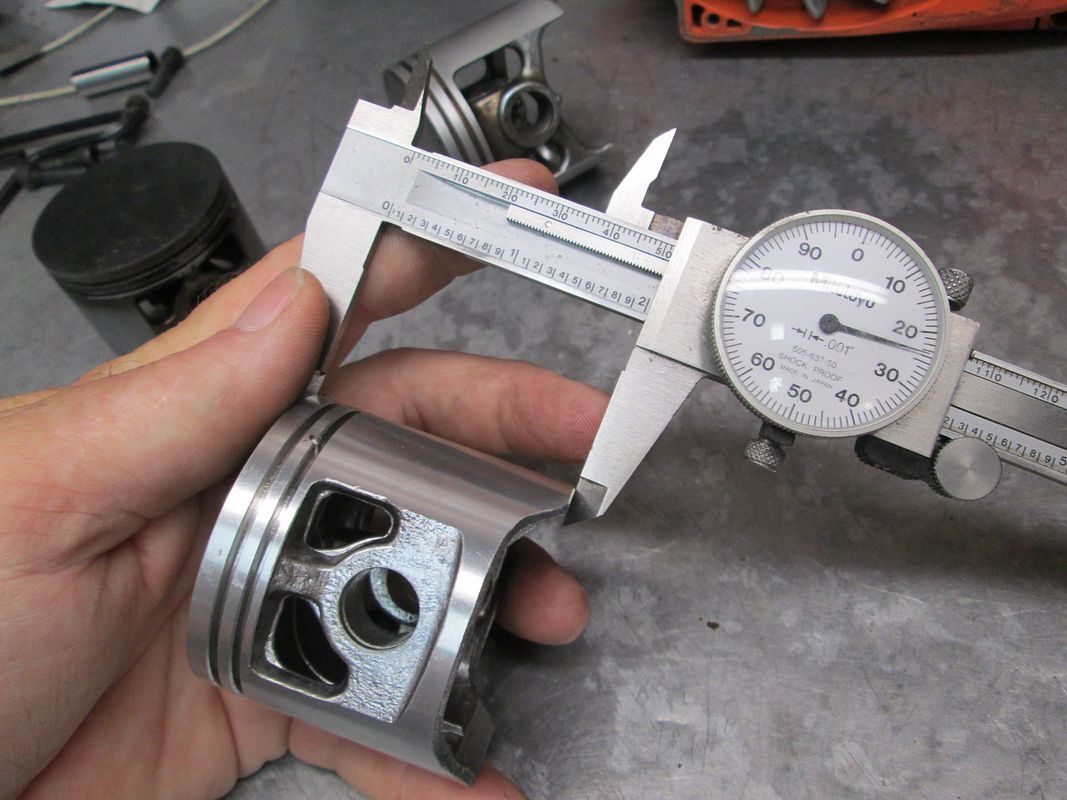

And a KS windowed version.

In this configuration, the designers added more intake timing, and lowered case compression.

Does anyone know which piston is the earlier design?

Now a Golf full skirt piston. It closely matches the KS slug.

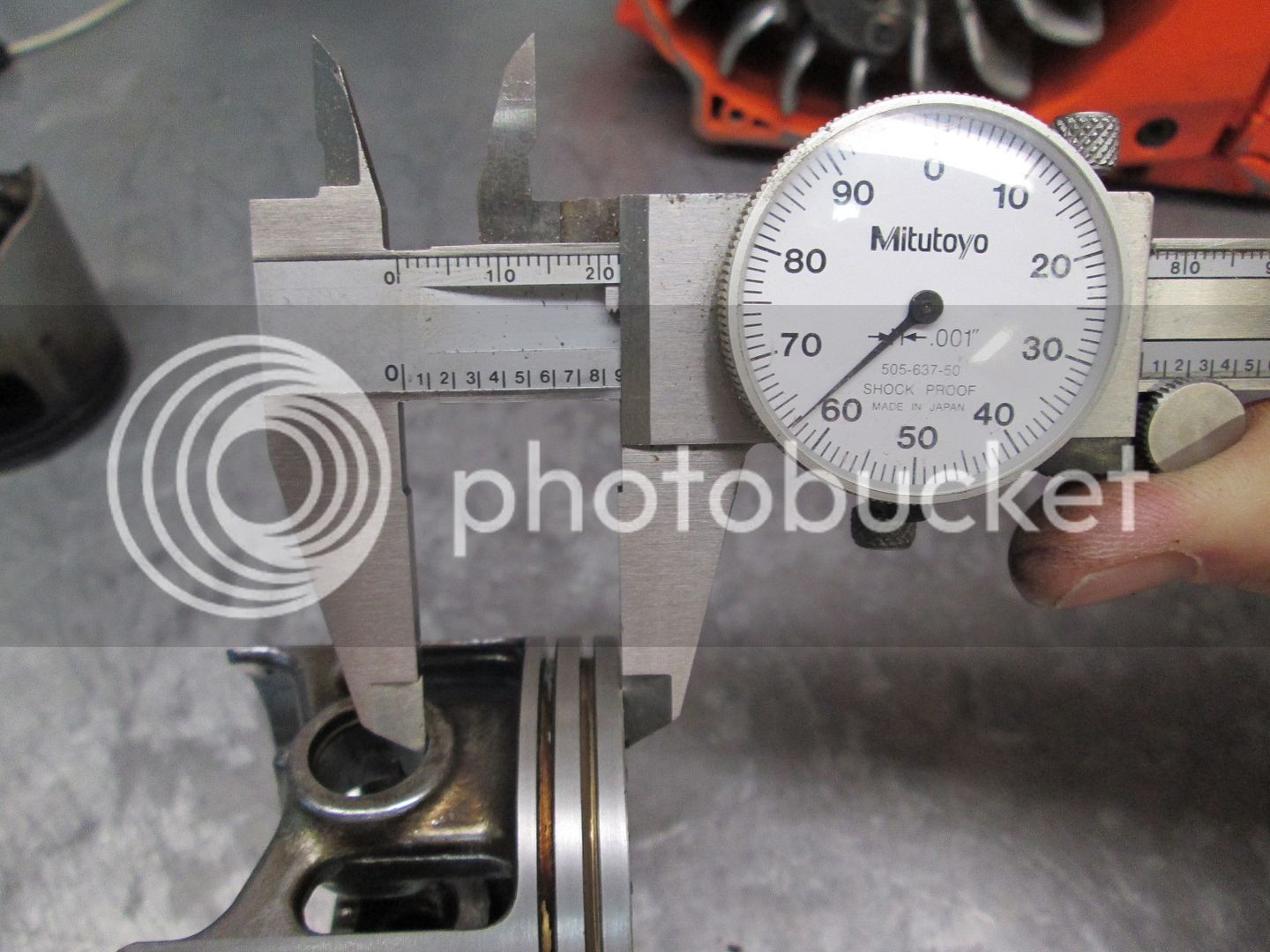

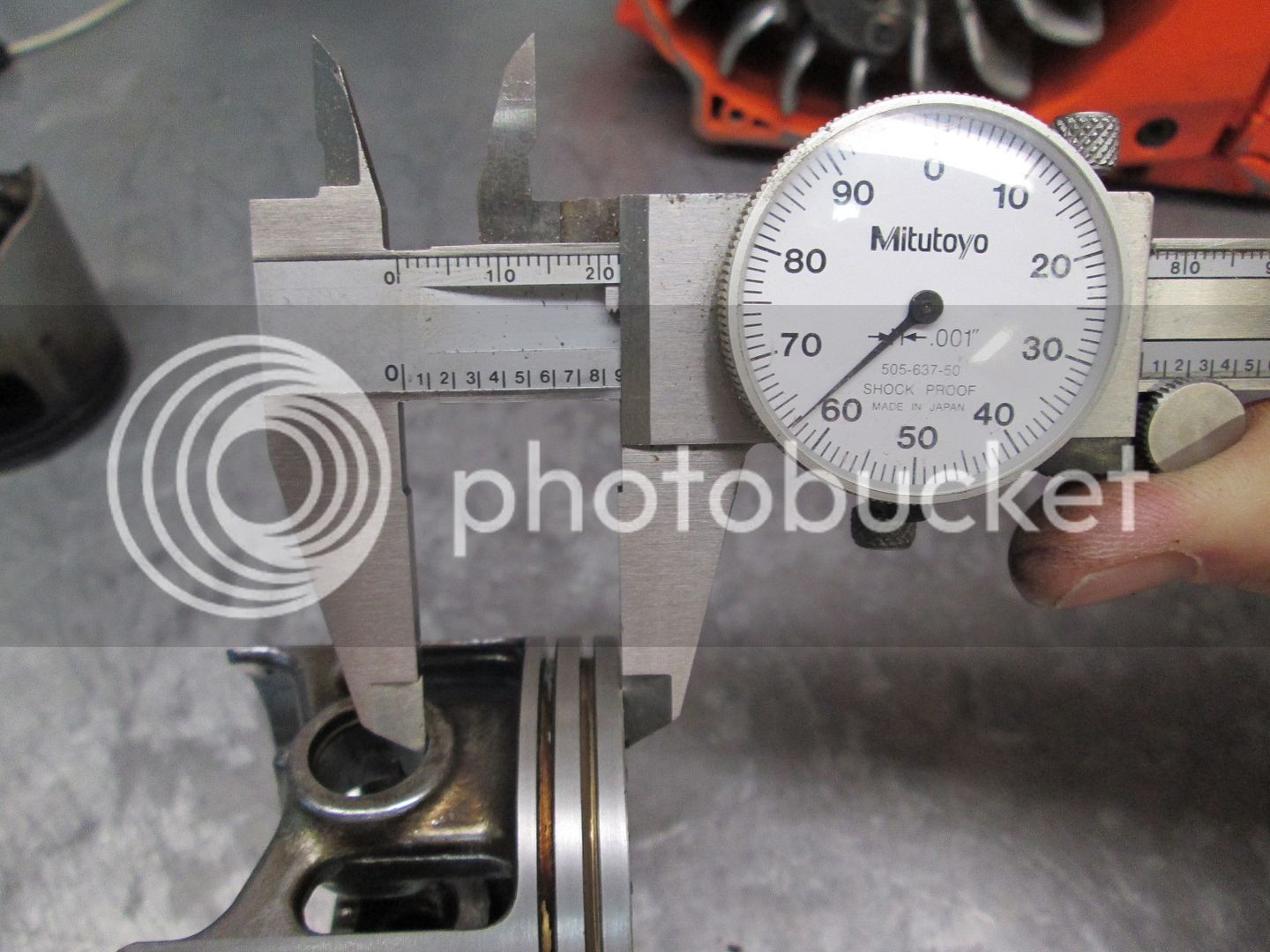

Pin to crown height on the full skirt KS piston.

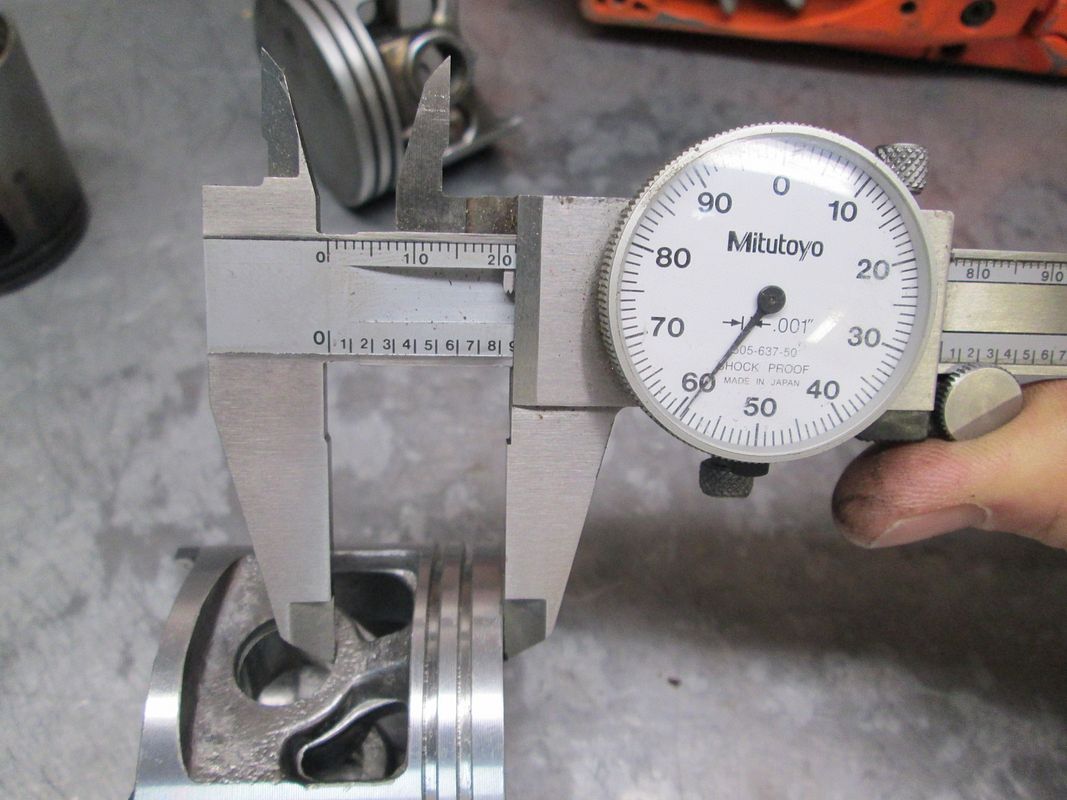

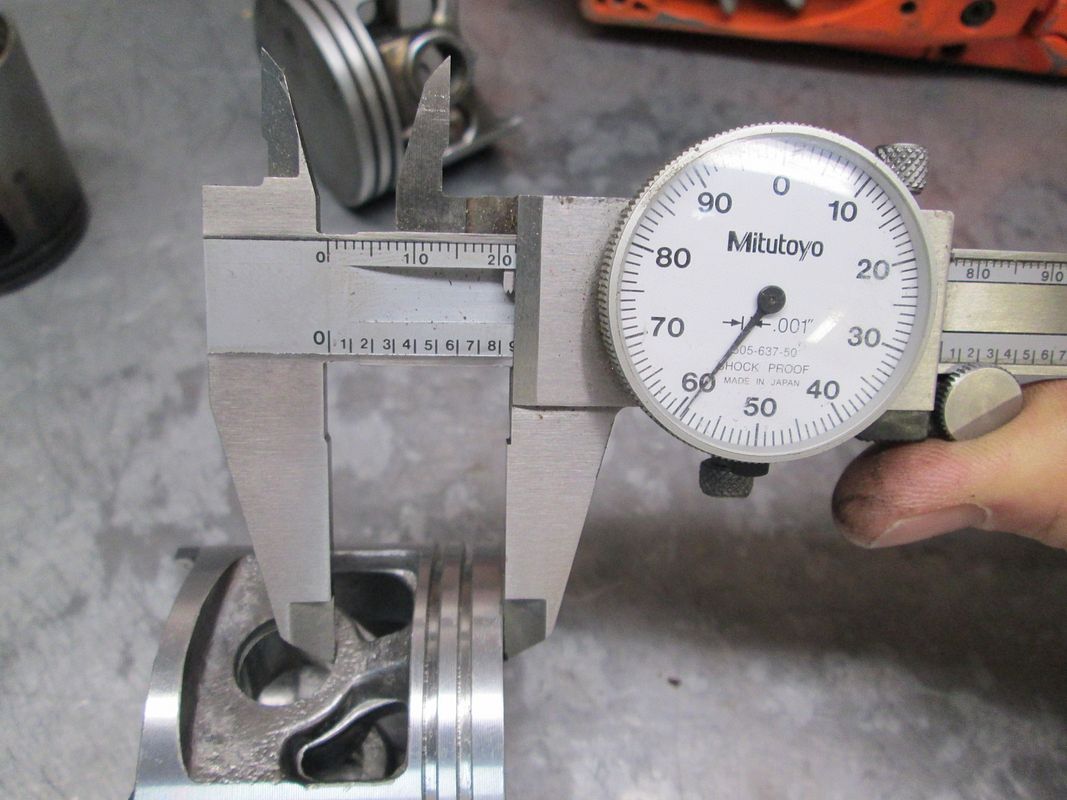

And the windowed KS. Not much different......so I'd feel safe running either design.

And the Golf......

I think I'd prefer the full skirt design because I like to see a lot of primary compression.......

This is a KS 2100XP full skirt piston.

And a KS windowed version.

In this configuration, the designers added more intake timing, and lowered case compression.

Does anyone know which piston is the earlier design?

Now a Golf full skirt piston. It closely matches the KS slug.

Pin to crown height on the full skirt KS piston.

And the windowed KS. Not much different......so I'd feel safe running either design.

And the Golf......

I think I'd prefer the full skirt design because I like to see a lot of primary compression.......