Figured I would start fresh instead of going through multiple threads for different questions....see how it goes I guess.

This thing would likely fire right up but figured I would tear it dowm, clean it up, and replace the few broken pieces and definately give it a bath

I'm at the point where I need some pointers on seperating the case, I have a gasket set on order and being the seals are about 7 years old, I want that piece of mind it will run for a few more years with little maintenance.

I peeked in the intake and I saw no scoring that would catch my attention, very, very faint marks that indicate an up & down motion on the piston but very shiny and likely oil streaks. Looks like the clutch is a reverse thread and the flywheel i'm not sure about. Do i need to pull the jug off to seperate the case and are there screws behind the flywheel and clutch?

To play the devils card, should I leave it be, clean it up and if the compression is good ( will check tomorrow) not seperate the case?

If it becomes a big ordeal once the case is seperated I will look at other options, I have no problem with the mechanics of this..not skeered .

.

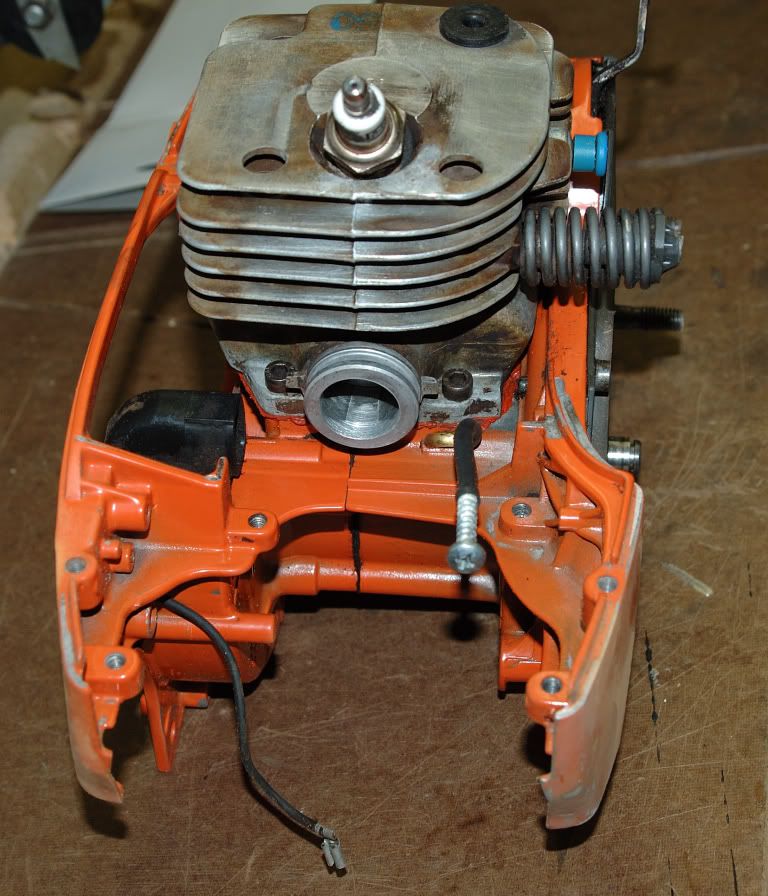

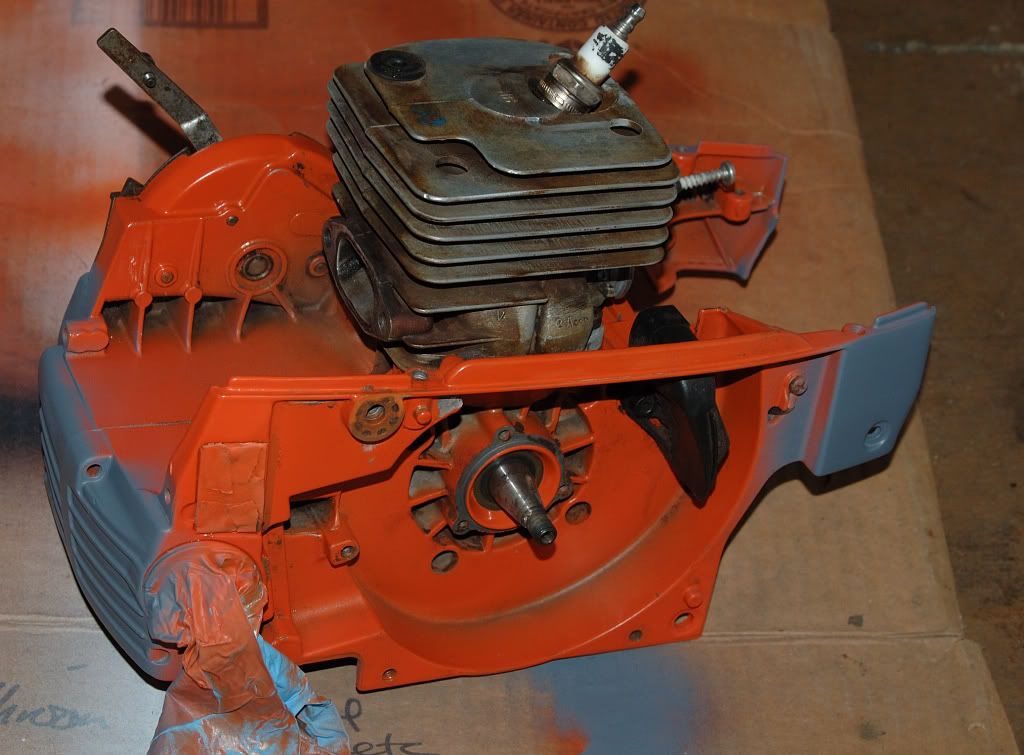

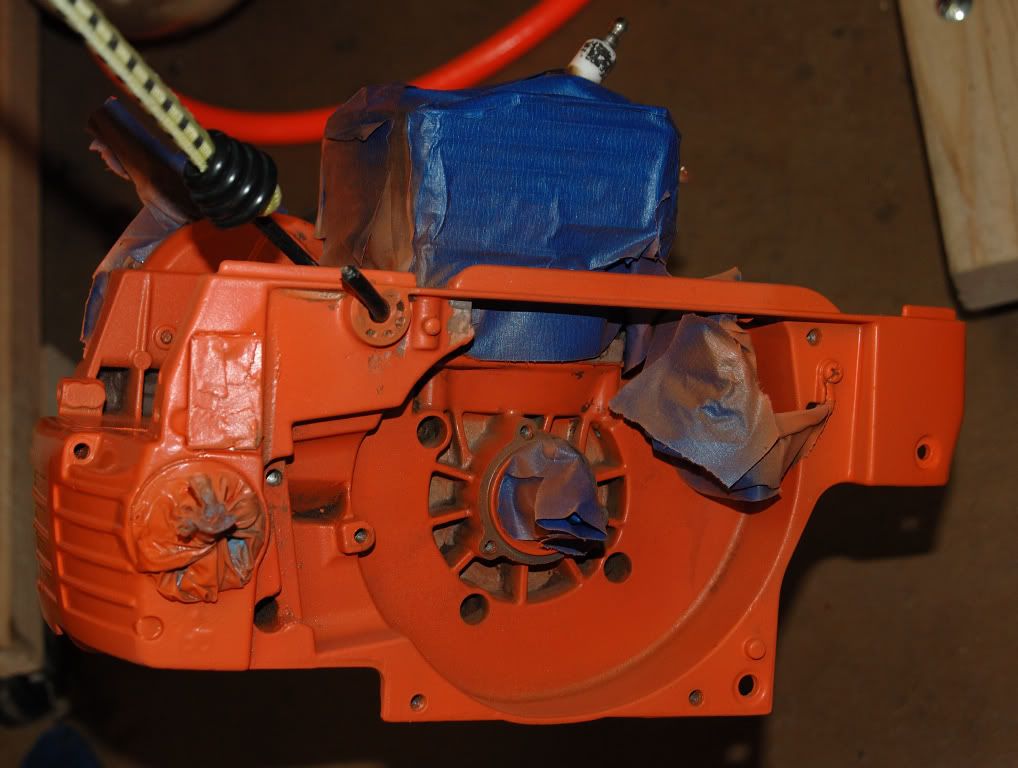

This is where i'm at. Any pointers are welcomed.

This thing would likely fire right up but figured I would tear it dowm, clean it up, and replace the few broken pieces and definately give it a bath

I'm at the point where I need some pointers on seperating the case, I have a gasket set on order and being the seals are about 7 years old, I want that piece of mind it will run for a few more years with little maintenance.

I peeked in the intake and I saw no scoring that would catch my attention, very, very faint marks that indicate an up & down motion on the piston but very shiny and likely oil streaks. Looks like the clutch is a reverse thread and the flywheel i'm not sure about. Do i need to pull the jug off to seperate the case and are there screws behind the flywheel and clutch?

To play the devils card, should I leave it be, clean it up and if the compression is good ( will check tomorrow) not seperate the case?

If it becomes a big ordeal once the case is seperated I will look at other options, I have no problem with the mechanics of this..not skeered

This is where i'm at. Any pointers are welcomed.