volks-man

Arboristsite.com Spooner

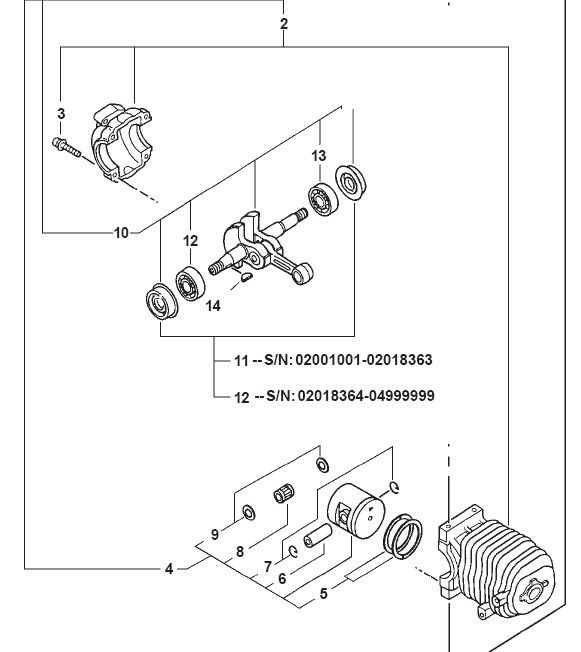

after my first, successful, porting job on my piston ported echo cs-440, i am thinking of opening up the little cs-346.

problem is that it is a reed valve motor. what differences am i likely to encounter inside this little saw?

do all the usual porting rules (ala blsnelling + others) apply?

pointers, tips, warnings?

thanks!

problem is that it is a reed valve motor. what differences am i likely to encounter inside this little saw?

do all the usual porting rules (ala blsnelling + others) apply?

pointers, tips, warnings?

thanks!