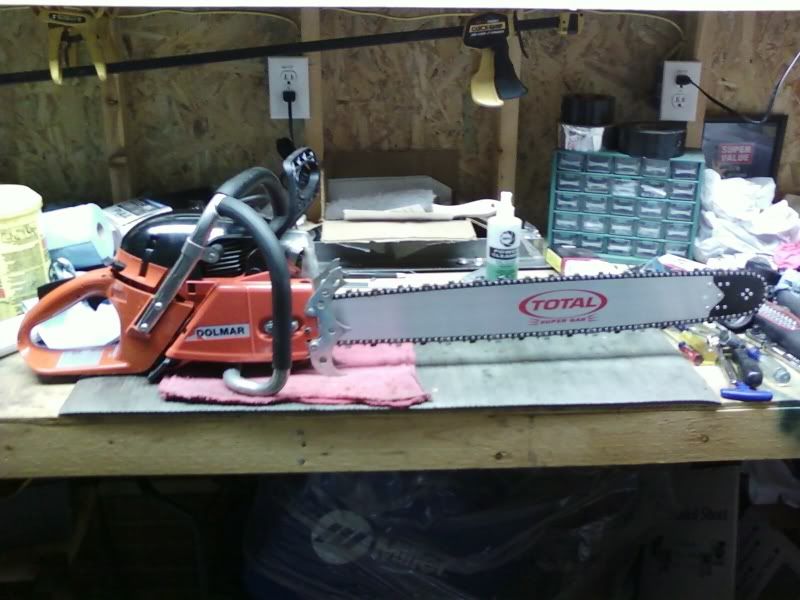

Ok, so after a bit of aftermarket refinery from my Canadian friends, here is the finished product (I am considering adding a muffler port, any thoughts on that?)-

So I am most curious about chains...

I have a preference toward STIHL chains even though I am not a fan of their saws... On this 28" inch, 3/8, .050 what would you folks recommend as far as STIHL chains? I believe the one on it is an RSK...

So I am most curious about chains...

I have a preference toward STIHL chains even though I am not a fan of their saws... On this 28" inch, 3/8, .050 what would you folks recommend as far as STIHL chains? I believe the one on it is an RSK...