Rudolf73

Addicted to ArboristSite

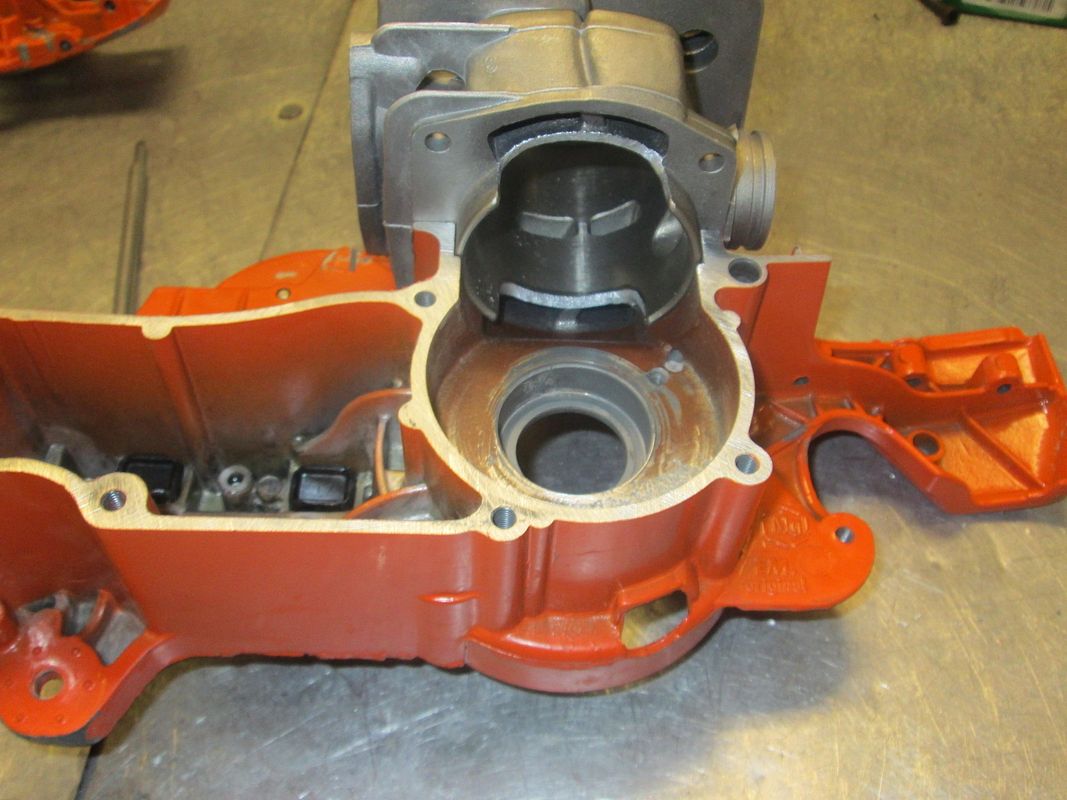

Intake timing ending up a little longer than I would have liked it.........but we'll see if it's a runner. I've got a few more pics.....but my camera is in the shop and I ain't unlocking the door. :msp_wink:

Did you have to do much to the exhaust roof? Some of the 372 BB kits have a funny shaped one.