kugss

ArboristSite Operative

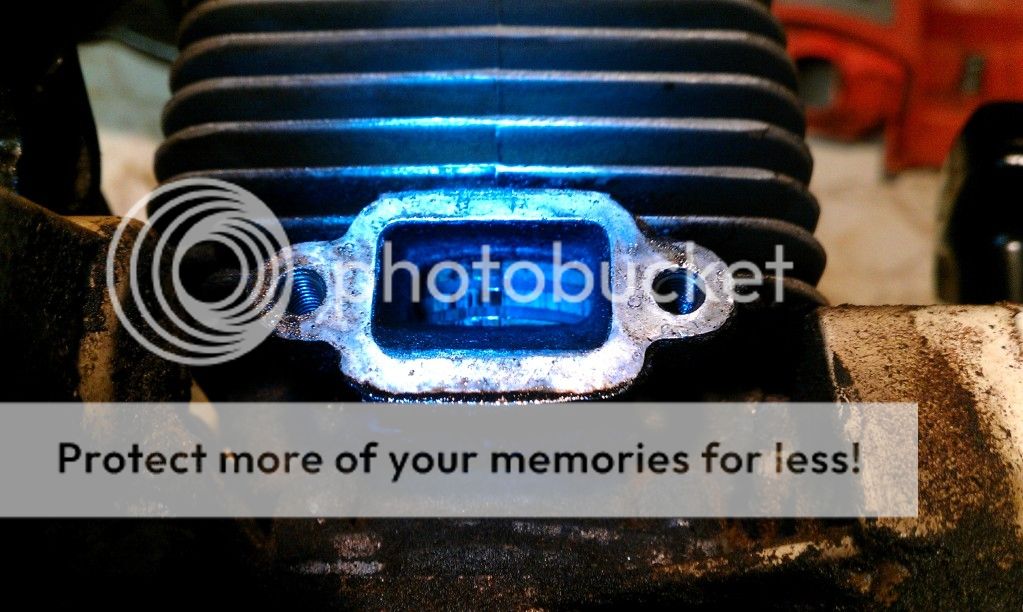

I pick up a 028 off of CL for 40$. Owner said piston was scored and the price seemed ok so it followed me back to my truck. It runs but not right wont idle down then it will stall and doesnt rev right. I did a compression check and got 150psi after 5-6 pulls so i did a tear down and clean and a vacuum check. It holds vacuum but leaks off but i think its my setup not the saw. So now its all clean and it went through the carb and all seems ok. I will run it tomorrw and see waht happens. What is a good starting point for the high and low screws on this saw? The marks on the piston are very light nothing to worry about (i think)

http://i826.photobucket.com/albums/zz189/KUGSS/IMAG0291.jpg

http://i826.photobucket.com/albums/zz189/KUGSS/IMAG0289.jpg

http://i826.photobucket.com/albums/zz189/KUGSS/IMAG0288.jpg

http://i826.photobucket.com/albums/zz189/KUGSS/IMAG0291.jpg

http://i826.photobucket.com/albums/zz189/KUGSS/IMAG0289.jpg

http://i826.photobucket.com/albums/zz189/KUGSS/IMAG0288.jpg

have them on close out

have them on close out