Jimmy in NC

Addicted to ArboristSite

The backstory:

Some may recall my 3120XP I had a few weeks back.. I had mentioned I really wanted a 372, 7900, etc and not a 120cc monster. It was in rough shape but in my eyes it was salvageable and not worth trashing but it would always be a bit big for a firewood saw.

Luckily Saw Doc had just what I needed, a project to swap for a project, a 365 Special that needed a over haul and top end.

I've ordered a Meteor top end from Randy with a full blown port job so I'm looking forward to running my first ported saw. The plan is to split the cases down to bare, clean, inspect, and build it up with new bearings, seals, etc and then scare local crews with a low top 365 that hauls butt!

I'm sure I'll have lots of questions along the way but right now I was wondering if anyone knew for sure what bearings the crank uses. I know I can split it and measure, etc but right now I have a 268 apart and some other saws apart waiting for parts. I hate to take too many apart at once as parts are always misplaced. If someone knows for sure I can go ahead and order the bearings, and hopefully around Christmas, get this saw together. I'll try to take plenty of pictures as everyone loves pictures although the old timers will probably be bored with another 372 build. It will also be my first build where I split the case and start from scratch and only the second one I've split.

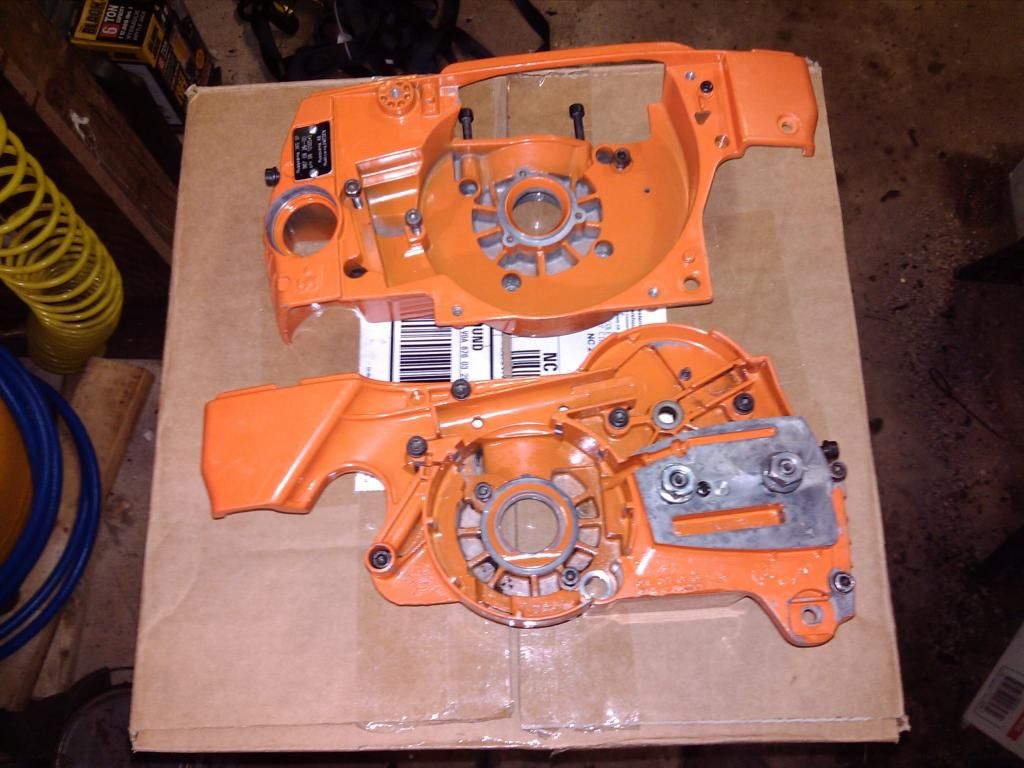

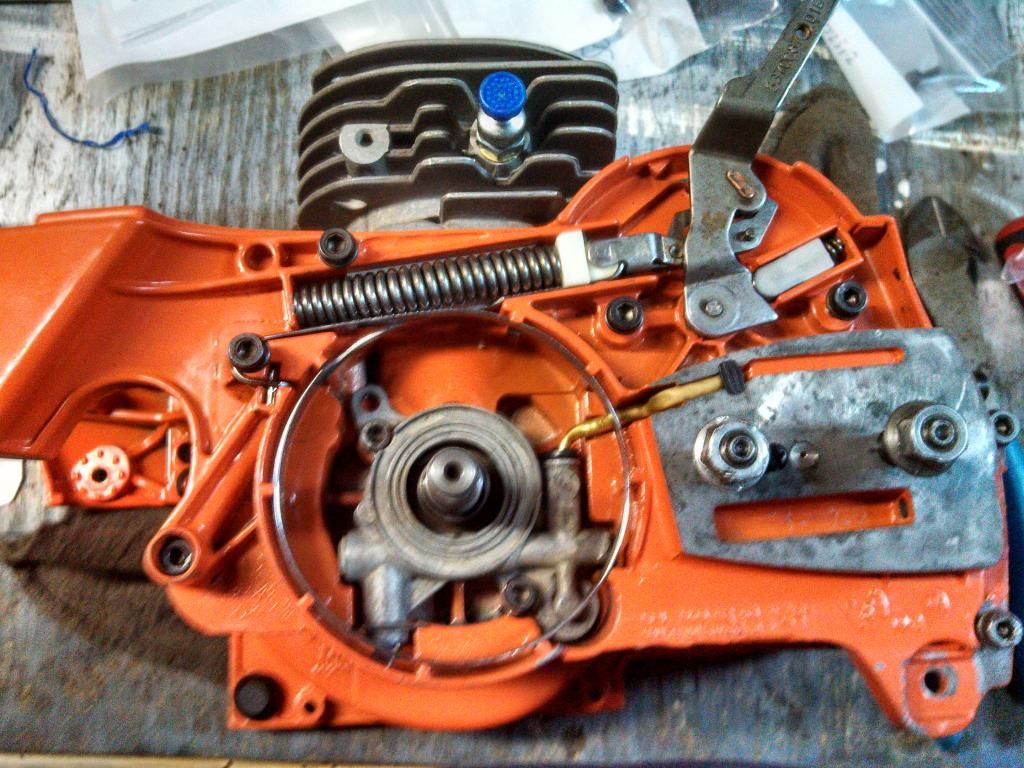

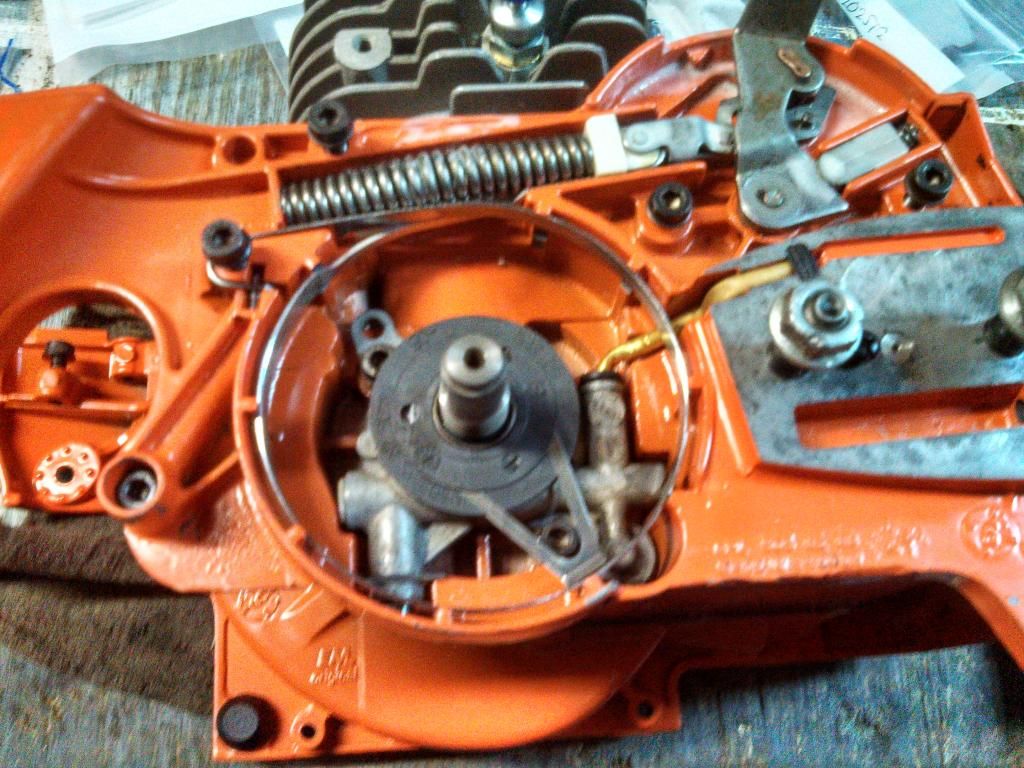

Picture of the first one I split...

I'm pretty sure that this one won't be that bad inside.. ok I know it won't!

So... anyone have a bearing number?!

Some may recall my 3120XP I had a few weeks back.. I had mentioned I really wanted a 372, 7900, etc and not a 120cc monster. It was in rough shape but in my eyes it was salvageable and not worth trashing but it would always be a bit big for a firewood saw.

Luckily Saw Doc had just what I needed, a project to swap for a project, a 365 Special that needed a over haul and top end.

I've ordered a Meteor top end from Randy with a full blown port job so I'm looking forward to running my first ported saw. The plan is to split the cases down to bare, clean, inspect, and build it up with new bearings, seals, etc and then scare local crews with a low top 365 that hauls butt!

I'm sure I'll have lots of questions along the way but right now I was wondering if anyone knew for sure what bearings the crank uses. I know I can split it and measure, etc but right now I have a 268 apart and some other saws apart waiting for parts. I hate to take too many apart at once as parts are always misplaced. If someone knows for sure I can go ahead and order the bearings, and hopefully around Christmas, get this saw together. I'll try to take plenty of pictures as everyone loves pictures although the old timers will probably be bored with another 372 build. It will also be my first build where I split the case and start from scratch and only the second one I've split.

Picture of the first one I split...

I'm pretty sure that this one won't be that bad inside.. ok I know it won't!

So... anyone have a bearing number?!