Anyone got any tips on how to unravel a chain after its been in the box and you take it out to use it. Eventually I can get it unraveled but it takes a lot of trial and error, so I am guessing it is taking a lot longer than it should, or at least it is taking longer than I want it to.

Unraveling tips?

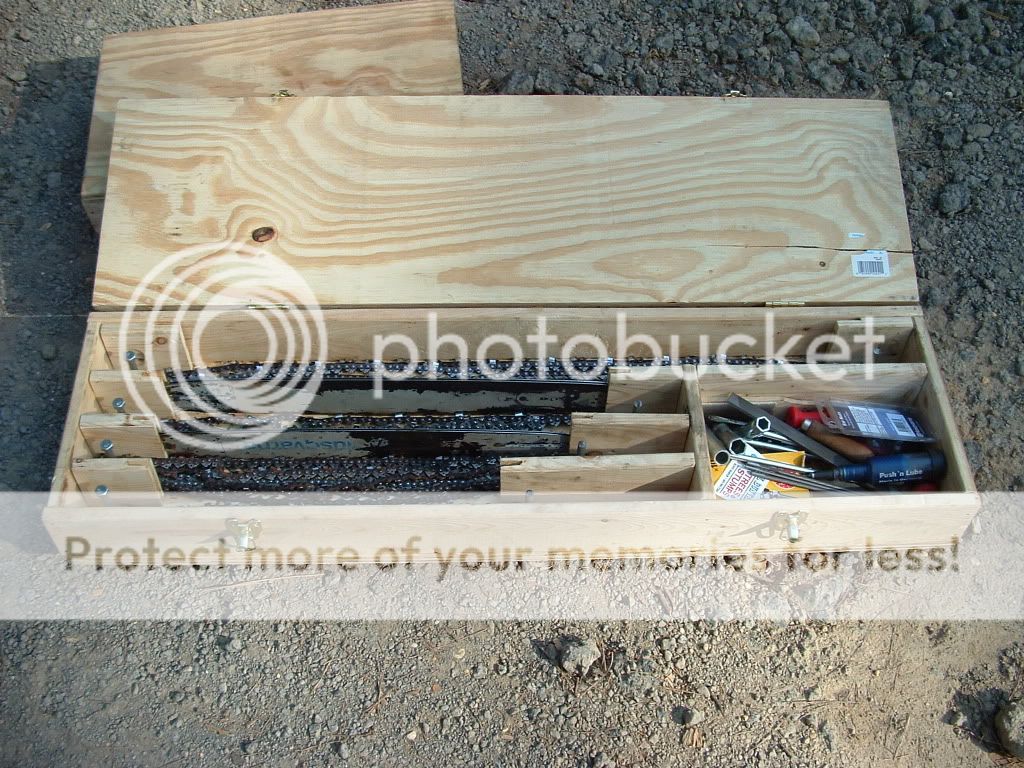

What about storage tips, maybe so when I do go to use it the thing wont be so twisted up?

Thanks

Unraveling tips?

What about storage tips, maybe so when I do go to use it the thing wont be so twisted up?

Thanks