Morning all,

Right off the bat, this is more of a "what if" thread than anything. I don't have the time for another project (but I always have time to think about silly stuff like this)

So, I work at a University, and there are a handful of those DIY motorized bikes around the campus running small (50-80cc I believe) 2 stroke engines. The other day, I noticed the physical similarity between those motors and the motor in my MS390. Of course that got me wondering....

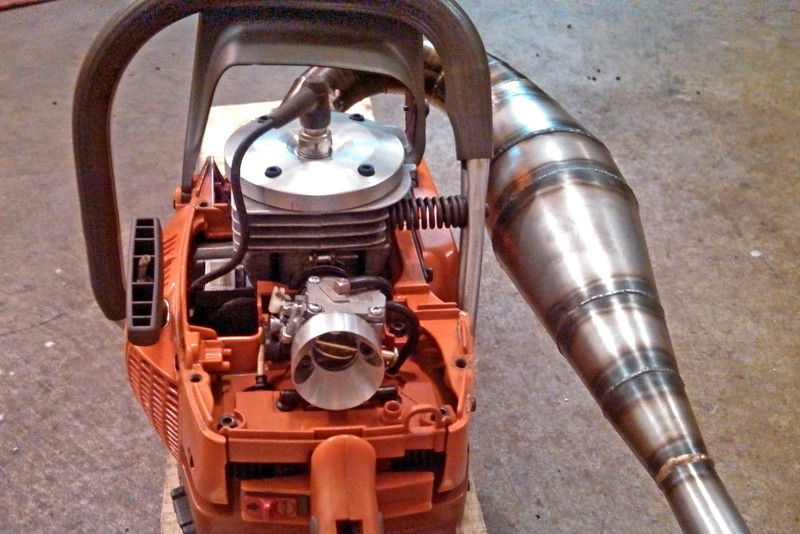

I know that there are tuned pipes available for those conversions, and the similarity got me wondering if there's any chance that the pipe from one of those bikes would be even close to appropriately sized for a similar displacement chainsaw. I had the chance to handle a broken one a while back and holding it up against my saw, it was even configured pretty well in terms of shape.

I know that pipes are designed around a specific rpm range and displacement. I don't know enough about the math to evaluate the performance potential of one of those pipes, but I figured that since every piped chainsaw I've seen looks like a custom job somebody around here might know how far off center this idea is likely to be. I wouldn't expect an off the shelf fit, but if it could be made to work with slight modifications (IE, mounts, changing the flange or headpipe, maybe a little sectioning), it might make a fun weekend project for someone's knockabout saw (Plus I'd love to see someone give it a try!)

Thanks guys.

Right off the bat, this is more of a "what if" thread than anything. I don't have the time for another project (but I always have time to think about silly stuff like this)

So, I work at a University, and there are a handful of those DIY motorized bikes around the campus running small (50-80cc I believe) 2 stroke engines. The other day, I noticed the physical similarity between those motors and the motor in my MS390. Of course that got me wondering....

I know that there are tuned pipes available for those conversions, and the similarity got me wondering if there's any chance that the pipe from one of those bikes would be even close to appropriately sized for a similar displacement chainsaw. I had the chance to handle a broken one a while back and holding it up against my saw, it was even configured pretty well in terms of shape.

I know that pipes are designed around a specific rpm range and displacement. I don't know enough about the math to evaluate the performance potential of one of those pipes, but I figured that since every piped chainsaw I've seen looks like a custom job somebody around here might know how far off center this idea is likely to be. I wouldn't expect an off the shelf fit, but if it could be made to work with slight modifications (IE, mounts, changing the flange or headpipe, maybe a little sectioning), it might make a fun weekend project for someone's knockabout saw (Plus I'd love to see someone give it a try!)

Thanks guys.