BigRed96

ArboristSite Operative

I have seen powerhead vises before and thought it might be handy when working on a saw since I don't have three hands. I had some scrap left over from a previous project and thought that I would try to construct one because I am cheap and I like building stuff. For those of you who haven't seen it I posted a thread on a DIY $21.49 Chain vise. That thread can be viewed here. I get to a $2.22 Powerhead vise using materials left over from that project. To begin the only parts I needed to buy were the following;

M8-1.25x22mm Metric Socket Cap Screws 2 @ .74 cents each

M8 Zinc-Plated Nylon Lock Nut 2 @ .37 cents each

The prices for the steel can be found in the chain vise thread.

The first thing I did was to decide how tall to make the portion that mounts into the vice. Honestly I can't remember how long I made it. This is the portion held in a bench vise and how you adjust the height of the chainsaw vise, so give yourself some room. Anyway, once you make up your mind on the length you will need to cut it from the 1 1/4 inch angle iron you had left from our last project.

Step two is to cut a square to weld on top of the first piece. Once again, I can't remember the exact measurements I made it but it's just a square.

Here is a pic of the square welded to piece number one and you can also see a pilot hole drilled in the center of the square. That is the next step.

The pilot hole size is irrelevant but the final size for the 8mm bolt is 5/16.

In the last picture you will see a bolt with a new piece of steel and a nylon nut holding it together. I welded the bolt head on the bottom side to the piece of steel so I don't have to worry about putting a wrench on it to tighten it.

As mentioned you can see the second piece of steel and how it will be used. This is also a piece of the same angle iron used before. Here is a piece of the steel before I cut a square out and drilled a hole.

Please disregard the square cut away as the project was originally going to use wingnuts but I couldn't get them tight enough to hold by hand. The cutout was to give access to the wingnut for adjustment. Once again I am not sure on the length. I think it is four inches. Once cut you will need to find the center and drill another 5/16 hole on the bottom side of the angle. Also you will see the next step which is to find the center of the opposing end and other side of the angle and drill a 5/16 hole. You can also see I added our next bolt and welded the head to the steel.

Next, we will begin our third and final piece of steel. To figure out the length I need it I just held the steel up next to one off my saws and eyeballed it. In the picture you can't see the whole piece but what you do see are the two holes I drilled for the bar studs to go thru. The holes are also 5/16.

Now I wanted this vise to be used with a multitude of saws so I made the two holes around three inches apart. I don't have a mill so I did this the hillbilly way. Same way I do most of my S-word. I drew lines from the tops and bottoms of the two holes then proceeded to cut the lines with a cut off wheel.

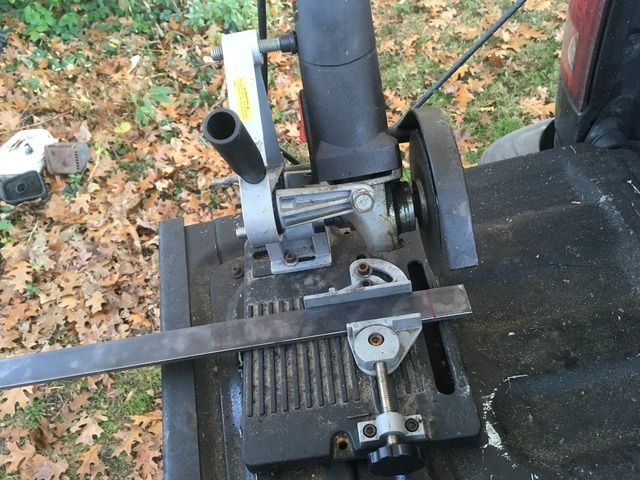

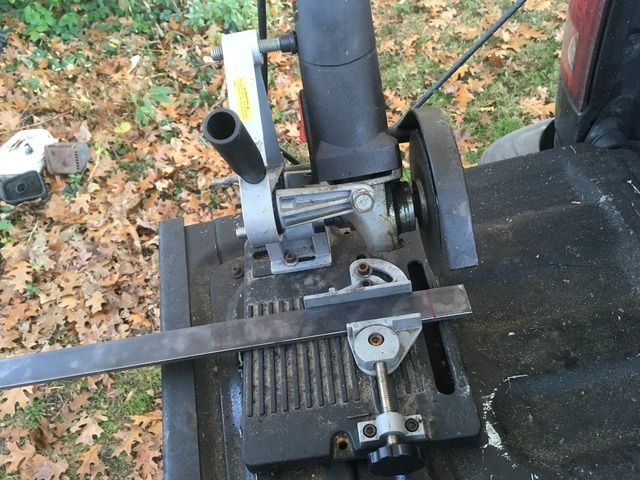

You can also see in the picture where I had to make a relief cut for the Stihl chain tensioner. Pretty self explanatory. Also you will see the 5/16 hole drilled in the center of the other end. Once completed you can bolt it all together and it should look something like this.

Here are some shots of the vise in action.

M8-1.25x22mm Metric Socket Cap Screws 2 @ .74 cents each

M8 Zinc-Plated Nylon Lock Nut 2 @ .37 cents each

The prices for the steel can be found in the chain vise thread.

The first thing I did was to decide how tall to make the portion that mounts into the vice. Honestly I can't remember how long I made it. This is the portion held in a bench vise and how you adjust the height of the chainsaw vise, so give yourself some room. Anyway, once you make up your mind on the length you will need to cut it from the 1 1/4 inch angle iron you had left from our last project.

Step two is to cut a square to weld on top of the first piece. Once again, I can't remember the exact measurements I made it but it's just a square.

Here is a pic of the square welded to piece number one and you can also see a pilot hole drilled in the center of the square. That is the next step.

The pilot hole size is irrelevant but the final size for the 8mm bolt is 5/16.

In the last picture you will see a bolt with a new piece of steel and a nylon nut holding it together. I welded the bolt head on the bottom side to the piece of steel so I don't have to worry about putting a wrench on it to tighten it.

As mentioned you can see the second piece of steel and how it will be used. This is also a piece of the same angle iron used before. Here is a piece of the steel before I cut a square out and drilled a hole.

Please disregard the square cut away as the project was originally going to use wingnuts but I couldn't get them tight enough to hold by hand. The cutout was to give access to the wingnut for adjustment. Once again I am not sure on the length. I think it is four inches. Once cut you will need to find the center and drill another 5/16 hole on the bottom side of the angle. Also you will see the next step which is to find the center of the opposing end and other side of the angle and drill a 5/16 hole. You can also see I added our next bolt and welded the head to the steel.

Next, we will begin our third and final piece of steel. To figure out the length I need it I just held the steel up next to one off my saws and eyeballed it. In the picture you can't see the whole piece but what you do see are the two holes I drilled for the bar studs to go thru. The holes are also 5/16.

Now I wanted this vise to be used with a multitude of saws so I made the two holes around three inches apart. I don't have a mill so I did this the hillbilly way. Same way I do most of my S-word. I drew lines from the tops and bottoms of the two holes then proceeded to cut the lines with a cut off wheel.

You can also see in the picture where I had to make a relief cut for the Stihl chain tensioner. Pretty self explanatory. Also you will see the 5/16 hole drilled in the center of the other end. Once completed you can bolt it all together and it should look something like this.

Here are some shots of the vise in action.