I finally got a used Silver RazurSharp II grinder. I've been wanting to go to square chains for a while but am not willing to file all my work chains. I never sharpen a chain in the field. I just take plenty of spares.

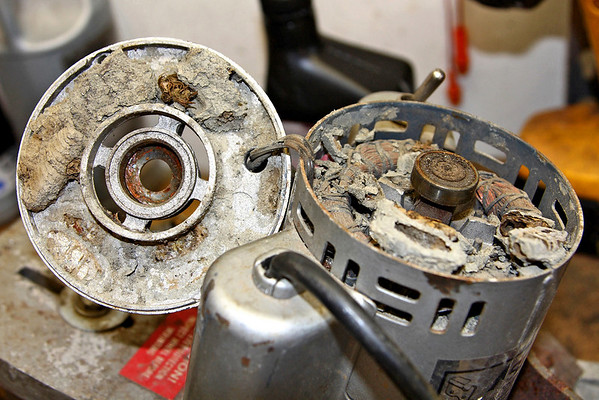

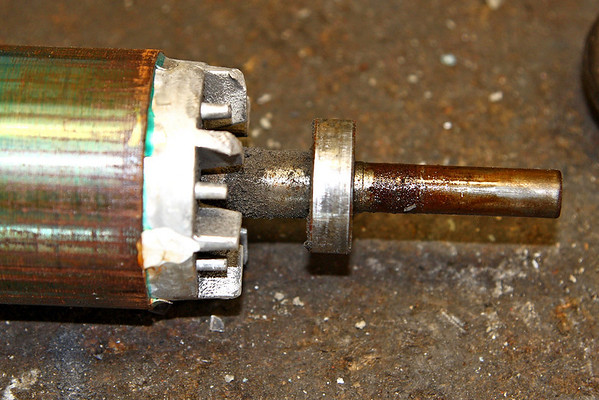

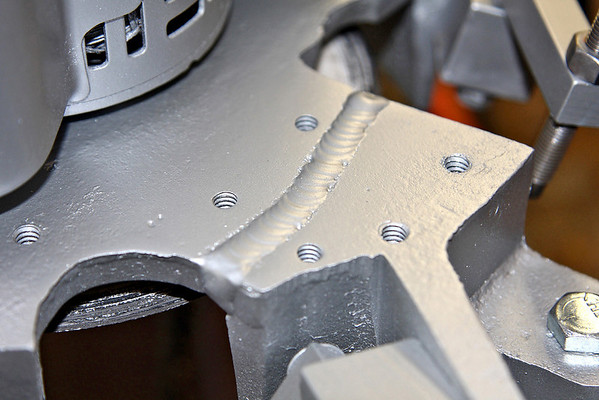

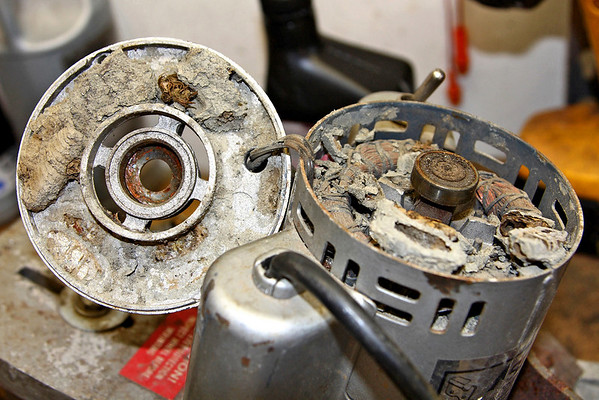

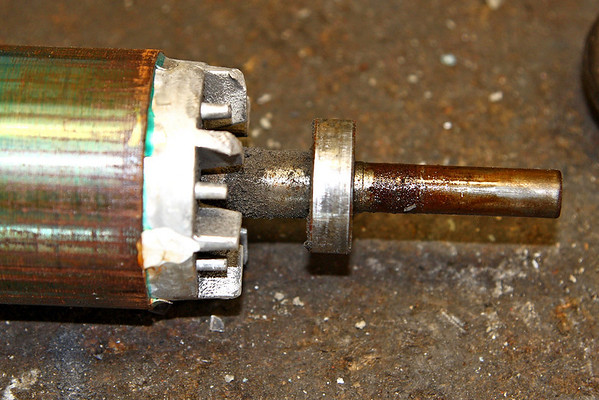

Anyway, I got little "more" than I bargained for, as often happens on eBay and Craigslist deals. I bought this particular grinder off Craigslist on the west coast. The grinder was tossed in a box and some newspaper wadded up around it. Hardly sufficient for a heavy grinder. The work light was broken off the motor and the lamp shade busted. Upon taking the end of the motor off to fix the light, I found that the end of the motor was full of dried mud from mud dabbers or the like. It's a good thing I had reason to go in there so that I could clean it all out. The bearing was also a little gritty so I popped the seal, cleaned it out and regreased it. It's now smooth as silk. Believe it or not, it all cleaned up real well and should be good to go for a long time now. While the grinder's apart, I'm cleaning it up and going to give it a fresh coat of paint. Now I've just got to figure out how to setup and use this thing!

Anyway, I got little "more" than I bargained for, as often happens on eBay and Craigslist deals. I bought this particular grinder off Craigslist on the west coast. The grinder was tossed in a box and some newspaper wadded up around it. Hardly sufficient for a heavy grinder. The work light was broken off the motor and the lamp shade busted. Upon taking the end of the motor off to fix the light, I found that the end of the motor was full of dried mud from mud dabbers or the like. It's a good thing I had reason to go in there so that I could clean it all out. The bearing was also a little gritty so I popped the seal, cleaned it out and regreased it. It's now smooth as silk. Believe it or not, it all cleaned up real well and should be good to go for a long time now. While the grinder's apart, I'm cleaning it up and going to give it a fresh coat of paint. Now I've just got to figure out how to setup and use this thing!