You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Husqvarna 162, 2x 266, 268 Frankensaw Project

- Thread starter briantutt

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Just as a note on power....

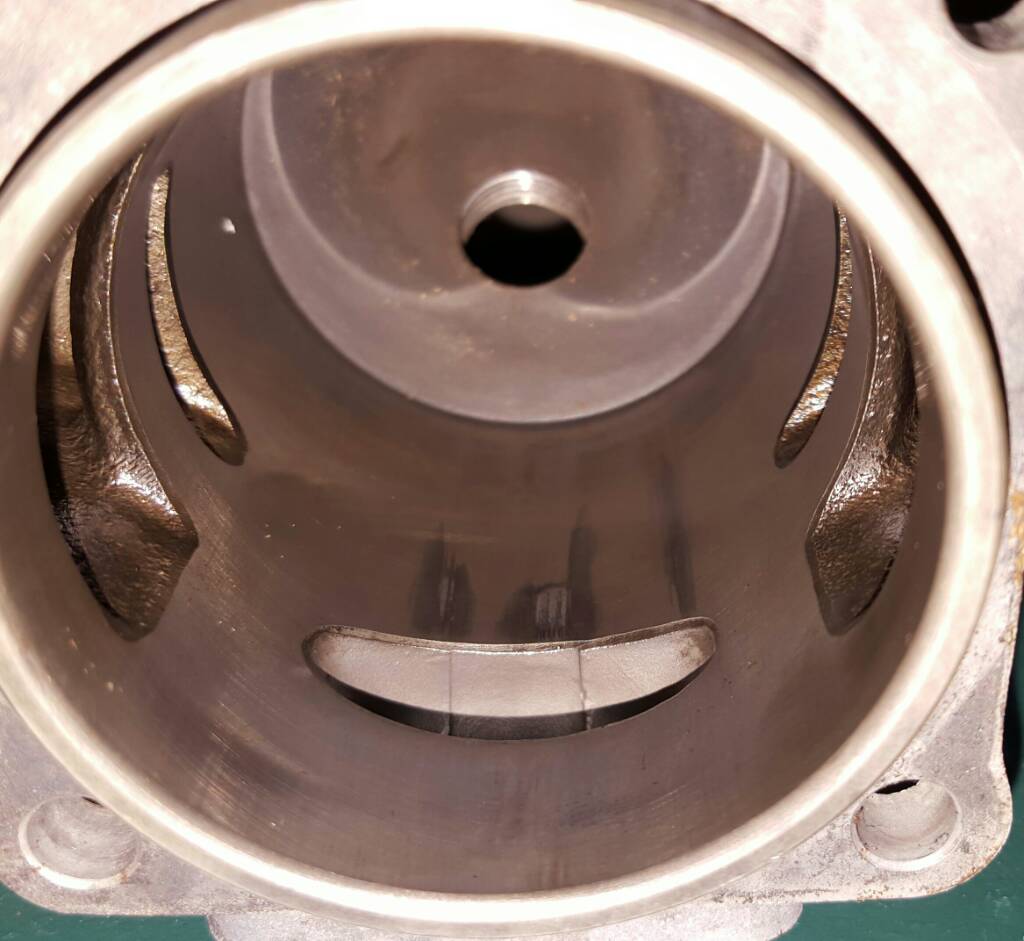

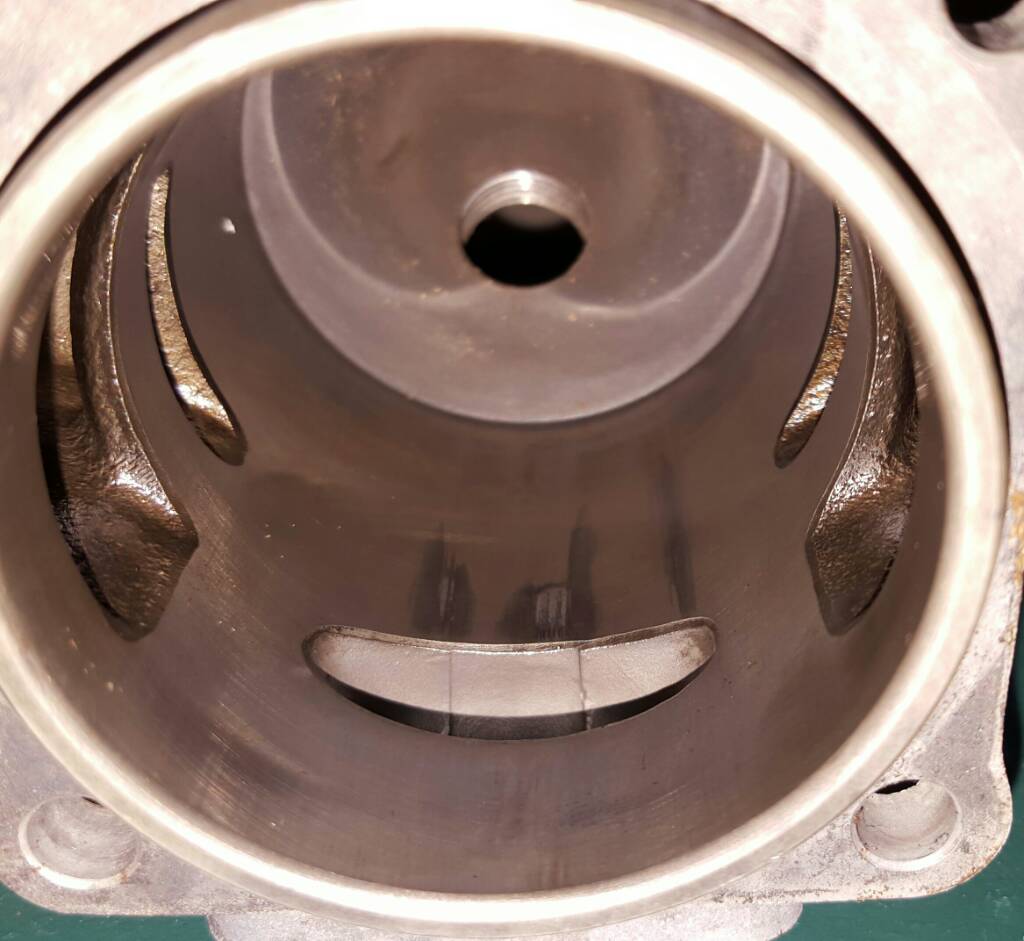

I built a 162se up and reused the old but good bearings but installed new seals.... Got a good used piston from bplust and I cleaned the badly transfer infused cylinder to be perfect.

I did a base gasket delete and let me tell ya, that closed port saw rips!!!

I sold it to a local pro firewood cutter who test ran it next to a perfect Echo CS-680 when he was trying to decide which saw to buy from me. The husky 162 outran and outcut the echo by enough difference to tell, and he couldn't bog the husky.

Anyways, not meaning to thread-jack, I am enjoying your build progress.

I built a 162se up and reused the old but good bearings but installed new seals.... Got a good used piston from bplust and I cleaned the badly transfer infused cylinder to be perfect.

I did a base gasket delete and let me tell ya, that closed port saw rips!!!

I sold it to a local pro firewood cutter who test ran it next to a perfect Echo CS-680 when he was trying to decide which saw to buy from me. The husky 162 outran and outcut the echo by enough difference to tell, and he couldn't bog the husky.

Anyways, not meaning to thread-jack, I am enjoying your build progress.

briantutt

Addicted to ArboristSite

I have never done a gasket delete. I am a little nervous putting the 162 SE top end on the 266 SE case. Mostly the cranks look different so I am thinking to use the 162 crank in the 266 case just to make sure I don't goof the stroke up.

I also think I might as well use the 266 carburetor and air filter system as well since it doesn't have the internal blockage from the case intake adaptor.

I also think I might as well use the 266 carburetor and air filter system as well since it doesn't have the internal blockage from the case intake adaptor.

Yeah, I just check the squish with some solder wire in 4 places by sticking it through the spark plug hole with the cylinder installed snug on the case with no sealant.

My 162se had .021 squish all around

The base gasket was .020 thick so it made a good difference.

I sparingly used yamabond 4 for sealing the base of the cylinder.

Works great and really ups the compression and brings an old saw back to life.

I am at 6000 ft so I really needed some bump in compression.

As for cranks, the stroke is the same I believe on all of them from 162 up to a 272; only the bore gets bigger for increased displacement.

My 162se had .021 squish all around

The base gasket was .020 thick so it made a good difference.

I sparingly used yamabond 4 for sealing the base of the cylinder.

Works great and really ups the compression and brings an old saw back to life.

I am at 6000 ft so I really needed some bump in compression.

As for cranks, the stroke is the same I believe on all of them from 162 up to a 272; only the bore gets bigger for increased displacement.

I used the mastermind method

http://www.arboristsite.com/community/threads/how-to-remove-aluminum-transfer-without-acid.248325/

I would practice on some cylinders that are total junk first to get the hang of it.

I think I remember fixing the first cylinder I tried it on though!

http://www.arboristsite.com/community/threads/how-to-remove-aluminum-transfer-without-acid.248325/

I would practice on some cylinders that are total junk first to get the hang of it.

I think I remember fixing the first cylinder I tried it on though!

briantutt

Addicted to ArboristSite

I used the mastermind method

http://www.arboristsite.com/community/threads/how-to-remove-aluminum-transfer-without-acid.248325/

Just ordered a piston kit from lil' red barn for the 268, now incredibly distracted reading the entire mastermind thread. Then I will figure out how to get a pole barn spike into my dremel collet. Thanks for the link!

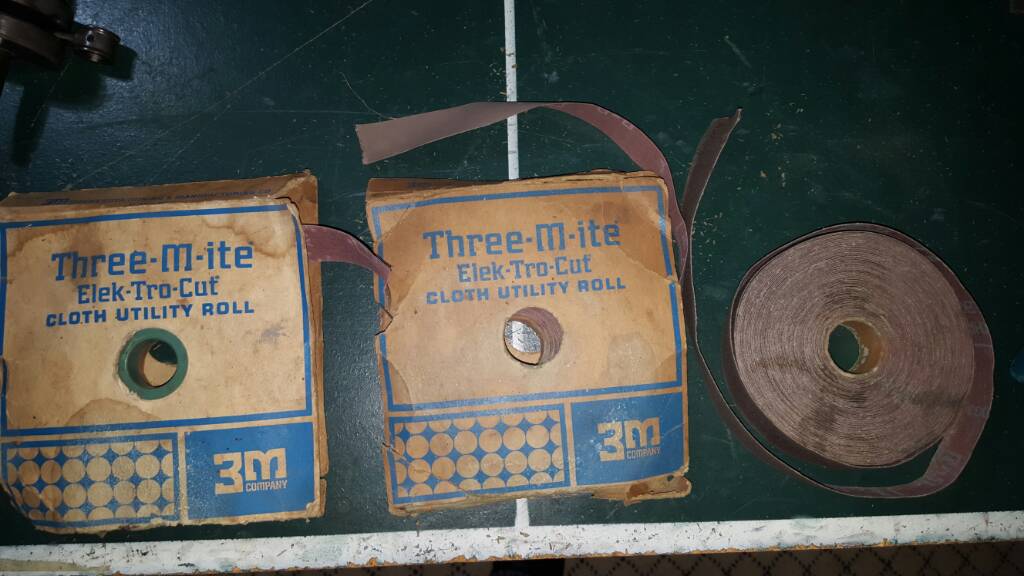

By the way, you can use a hand drill and a wood dowel to hold the Emory cloth for an easy starter setup.

Slot the end just enough to allow 1/8 of an inch of your Emory cloth to hang over the end

Roll up about 18 inches of Emory cloth onto the end shaped like a cylinder...

Let it slap and softly go over the transfer with very light pressure, cutting off loaded up Emory cloth very often

Slot the end just enough to allow 1/8 of an inch of your Emory cloth to hang over the end

Roll up about 18 inches of Emory cloth onto the end shaped like a cylinder...

Let it slap and softly go over the transfer with very light pressure, cutting off loaded up Emory cloth very often

briantutt

Addicted to ArboristSite

I will try my corded drill it goes 2100 on high speed. I have some drill rod bar stock that is .280 diameter that I will use for the holder. I may even try permanently attaching a holder straight into the collet holder on one of my dremels. 266 cylinder has more issues but I am only going to make one 266 I think so if I screw it up no loss.

Brian

Brian

briantutt

Addicted to ArboristSite

So I guess I should have took some measurements before it fully disassembled these. According to the service manuals there is a tool used to set the bearing location in the case half. The tool is around $50! Does anyone have a case split that could check the bearing location relative to the case with a caliper for me? Please!

The tool I don't have is below. I assume that lip sets the depth from the outside and you just set the bearing down from the inside. So all I need to know is either that lip height or bearing to case relative measurement on the inside.

Brian

The tool I don't have is below. I assume that lip sets the depth from the outside and you just set the bearing down from the inside. So all I need to know is either that lip height or bearing to case relative measurement on the inside.

Brian

Just put the bearings on the crank first, tight to the counterwieghts. Then put the crank with bearings on it in the flywheel side half first till the bearing bottoms in the case. Then put the clutch side half on. The bearings will be in the correct location when you are done. I usually use a toaster oven and freezer to heat or cool parts as nessecary so everything just slips together.

Similar threads

- Replies

- 15

- Views

- 34K

Latest posts

-

OLD husqvarna rancher 50 not starting - seems to have spark, compression, fuel, timing?

- Latest: Vintage Engine Repairs

-

-

-

-

-